Sinking pump automatic control device and control method thereof

An automatic control device and submersible pump technology, applied in pump control, machine/engine, liquid variable volume machinery, etc., can solve the problem of difficulty in controlling the start and stop time of submersible pumps, and avoid waste of personnel and eliminate accidents. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

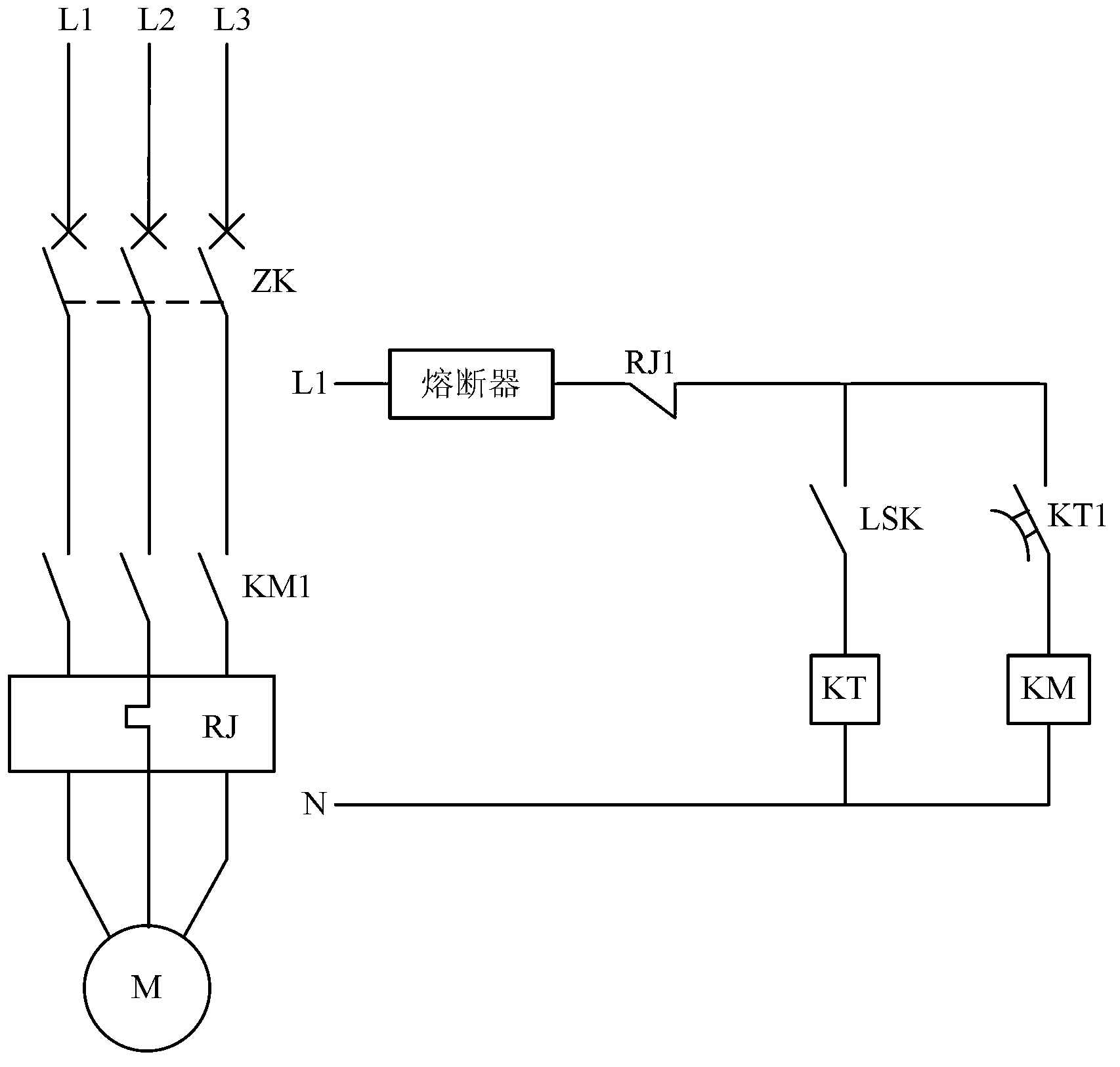

[0018] Specific implementation mode one: combine figure 1 Describe this embodiment, the submersible pump automatic control device described in this embodiment includes a submersible pump, a water level limiter, an AC contactor, a fuse, a time relay and a thermal relay, and the control coil KT of the time relay is connected to the water level limiter. The limit switch LSK of the meter is connected in series to form the first series branch, and the coil KM of the AC contactor is connected in series with the delay normally open contact KT1 of the time relay to form the second series branch, and the second series branch is connected in series with the first series branch. The branches are connected in parallel to form a parallel branch, and the parallel branch is connected in series with the normally closed contact RJ1 of the thermal relay and the fuse between any live wire and the neutral wire of the power supply circuit of the three-phase AC motor M of the submersible pump. The ...

specific Embodiment approach 2

[0020] Specific implementation mode two: combination figure 1 Describe this embodiment. The difference between this embodiment and the submersible pump automatic control device described in Embodiment 1 is that the device also includes an air switch ZK, which is connected in series to the power supply of the three-phase AC motor M of the submersible pump. in the loop.

specific Embodiment approach 3

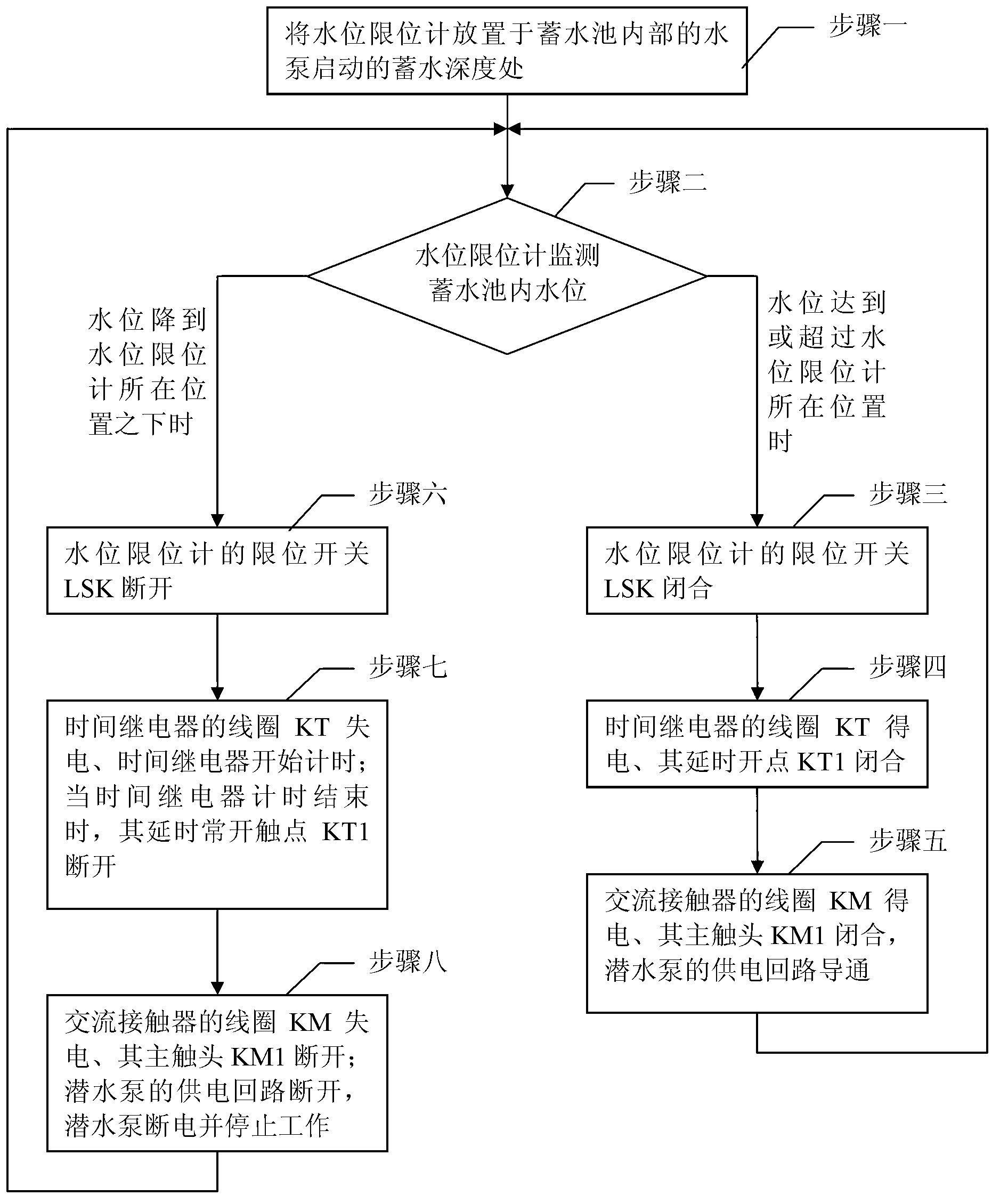

[0021] Specific implementation mode three: combination figure 2 This embodiment is described. This embodiment is based on the control method of the submersible pump automatic control device described in Embodiment 1. The control method is implemented through the following steps:

[0022] Step 1. Place the water level limiter at the water storage depth where the water pump inside the reservoir starts; perform step 2;

[0023] Step 2. The water level limit gauge monitors the water level in the reservoir. When the water level reaches or exceeds the position of the water level limit gauge, perform step 3; when the water level drops below the position of the water level limit gauge, perform step 6;

[0024] Step 3, the limit switch LSK of the water level limit gauge is closed, and step 4 is performed;

[0025] Step 4, the coil KT of the time relay is energized, and its time-delay normally open contact KT1 is closed; perform step 5;

[0026] Step 5: The coil KM of the AC contacto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com