Foam stabilizing technology for preparing foam-like fracturing fluid

A foam fracturing fluid and foam stabilization technology, which is applied in the directions of drilling compositions, chemical instruments and methods, etc., can solve the problem that the reaction of gas heat generating agent is difficult to control, affects the application range of a foam-like fracturing system, and cannot meet construction requirements. and other problems, to achieve the effects of controllable foaming time, improved performance, and increased foam stabilization ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A foam stabilizing process for preparing foam-like fracturing fluid, which comprises the following steps:

[0042] S1. Add a foam stabilizer to the foam-like fracturing fluid base fluid, and the amount of the foam stabilizer added is 1% of the base fluid weight;

[0043] S2. During the use of the foam-like fracturing fluid, acid catalyst A is added to the acidic liquid of the foam-like fracturing fluid, and the amount of acid catalyst A added is 3% of the weight of the acidic liquid.

[0044] It also includes a step for preparing a foam stabilizer, and the preparation method of the foam stabilizer is:

[0045] A1. Weigh the fatty alcohol polyoxyethylene ether and the sulfonating agent in a molar ratio of 1:1 for later use, add the weighed fatty alcohol polyoxyethylene ether into a clean 250ml three-necked flask, and raise the temperature to 85°C under stirring ;

[0046] A2. Slowly add the weighed sulfonating agent into the above-mentioned three-necked flask filled wi...

Embodiment 2

[0055] A foam stabilizing process for preparing foam-like fracturing fluid, which comprises the following steps:

[0056] S1, adding a foam stabilizer to the foam-like fracturing fluid base fluid, the amount of the foam stabilizer added is 0.5% of the base fluid weight;

[0057] S2. During the use of the foam-like fracturing fluid, acid catalyst A is added to the acidic liquid of the foam-like fracturing fluid, and the amount of acid catalyst A added is 1.0% of the weight of the acidic liquid.

[0058] It also includes a step for preparing a foam stabilizer, and the preparation method of the foam stabilizer is:

[0059] A1. Weigh the fatty alcohol polyoxyethylene ether and the sulfonating agent in a molar ratio of 1:1 for later use, add the weighed fatty alcohol polyoxyethylene ether into a clean 250ml three-necked flask, and raise the temperature to 80°C under stirring ;

[0060] A2. Slowly add the weighed sulfonating agent into the above-mentioned three-necked flask filled...

Embodiment 3

[0069] A foam stabilizing process for preparing foam-like fracturing fluid, which comprises the following steps:

[0070] S1. Adding a foam stabilizer to the base fluid of the foam-like fracturing fluid, the amount of the foam stabilizer added is 0.5-1.5% of the weight of the base fluid;

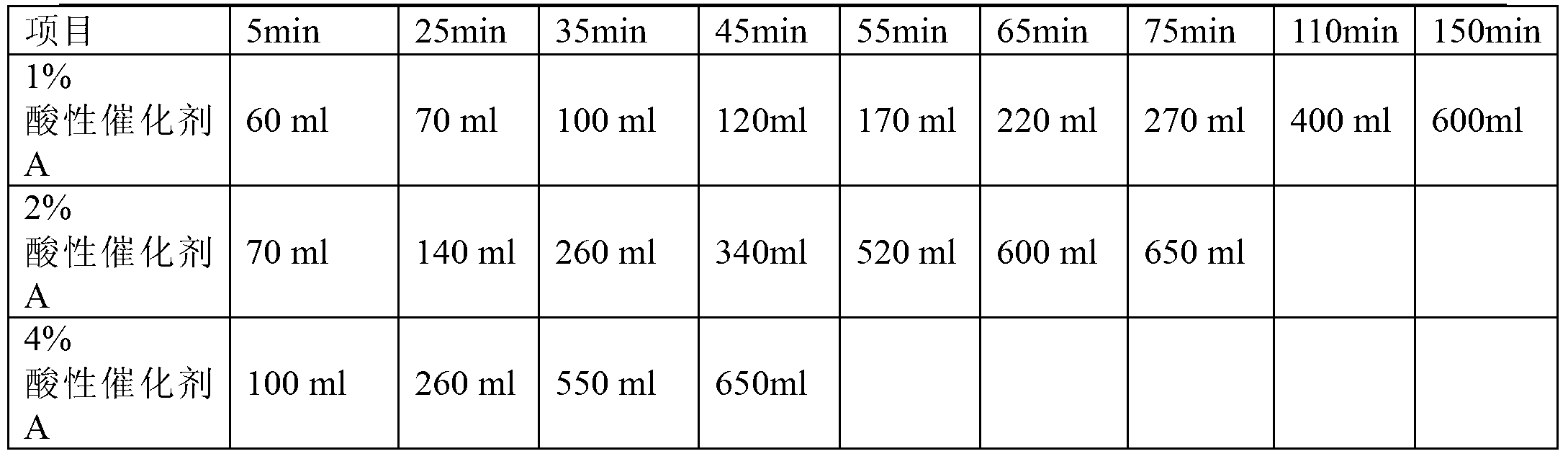

[0071] S2. During the use of the foam-like fracturing fluid, acid catalyst A is added to the acidic liquid of the foam-like fracturing fluid. The amount of acid catalyst A added is 1.0-5.0% by weight of the acidic liquid.

[0072] It also includes a step for preparing a foam stabilizer, and the preparation method of the foam stabilizer is:

[0073] A1. Weigh the fatty alcohol polyoxyethylene ether and the sulfonating agent in a molar ratio of 1:1 for later use, add the weighed fatty alcohol polyoxyethylene ether into a clean 250ml three-necked flask, and raise the temperature to 80°C under stirring ~90°C;

[0074] A2. Slowly add the weighed sulfonating agent into the above-mentioned three-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com