Refining method of styrene

A purification method, technology of styrene, applied in chemical instruments and methods, hydrocarbon purification/separation, chemical modification purification/separation, etc., can solve problems such as unfavorable environmental protection, toxicity, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

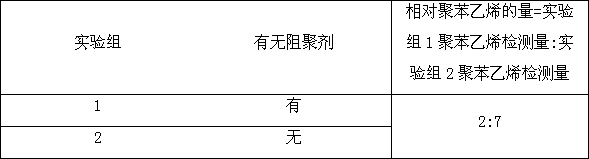

Image

Examples

Embodiment 1

[0029] 1 Preparation of catalyst

[0030] Weigh according to mass ratio: 10% ferric oxide, 15% potassium chromate, 2.4% calcium oxide, 12% zinc oxide, 6.2% aluminum oxide, and mix evenly to obtain a finished catalyst.

[0031] 2 catalytic reaction

[0032] Add above-mentioned catalyst in the crude product of styrene that contains ethylbenzene, the ratio of its addition is 100mg / l; Control reaction temperature is 550 ℃, reaction system pressure 0.7 atmospheric pressure, pass into reaction polymerization inhibitor in reaction system simultaneously, with To avoid self-polymerization of styrene monomers, the polymerization inhibitor is hydrogen peroxide vapor, and the amount of hydrogen peroxide vapor introduced is 2 / 3 of the volume of the reaction vessel.

[0033] (c) Sampling and testing the content of ethylbenzene in the styrene product obtained from the reaction. When the content of ethylbenzene is less than 0.1%, stop the reaction and filter to remove excess catalyst.

[00...

Embodiment 2

[0053] On the basis of Example 1, the iron-zinc catalytic hydrogenation system also includes 2.5% chromium oxide.

[0054] Its ethylbenzene conversion rate is 90%

Embodiment 3

[0055] Embodiment 3 reduction system comparison

[0056] Adopt the reducing system and step parameter in embodiment 1, embodiment 2, only adjust temperature.

[0057] The optimal reaction temperature is 560°C, 570°C, and 580°C respectively, and the conversion rate of ethylbenzene is investigated

[0058] temperature (°C) 560, conversion rate of ethylbenzene 570, conversion rate of ethylbenzene 580, conversion rate of ethylbenzene Embodiment 1 reaction system of the present invention 80 83 75 Embodiment 2 reaction system of the present invention 85 92 80

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com