Continuous punching and shearing machine

A technology of punching and shearing machines and punches, which is applied to metal processing equipment, forming tools, manufacturing tools, etc. It can solve the problems of oil pollution and heavy smell of coolant, affect the health of employees, and occupy a large area of the factory building, etc., and achieve low cost of tools , compact structure, and the effect of reducing the floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

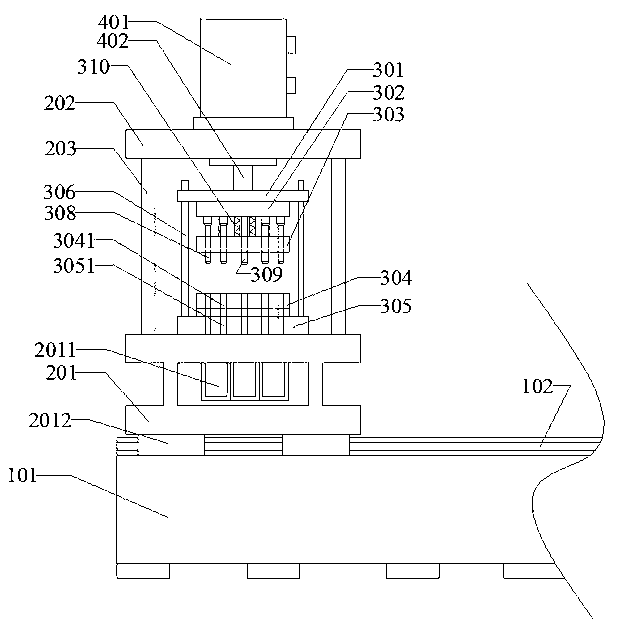

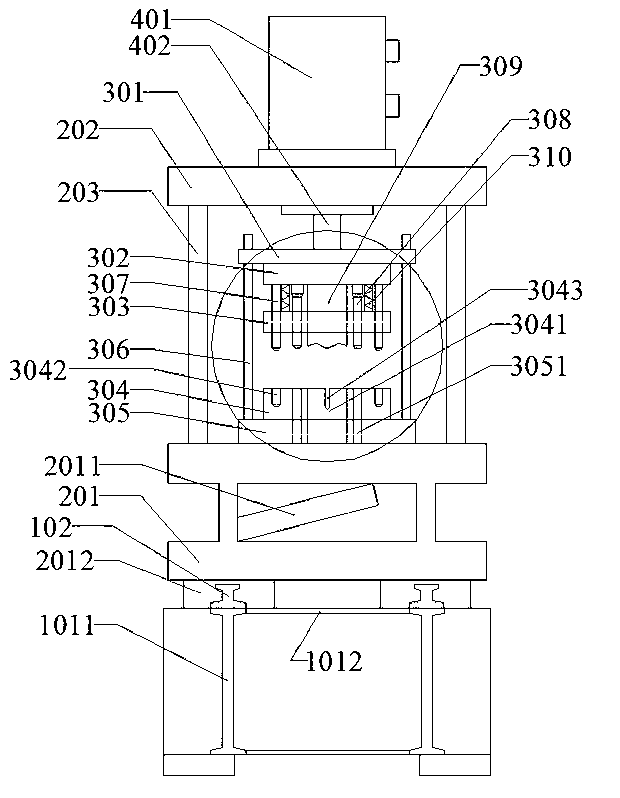

[0034] refer to Figure 2 to Figure 5 As shown, the online continuous punching and shearing machine suitable for hollow guide rails of the present invention includes: a reciprocating walking system, a punching and shearing system, and a control system.

[0035] Wherein, the reciprocating walking system includes: a slide rail base 101 , a sliding actuator disposed inside the slide rail base 101 , and a slide rail 102 disposed on the top surface of the slide rail base 101 .

[0036] The main function of the slide rail base 101 is to set and install the sliding actuator and the sliding track 102. The sliding actuator is used to provide a power source, so that the device for realizing punching and shearing can be extended along the direction of the hollow guide rail (also The hollow guide rail rolling production line (logistics direction) re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com