Fluidized vacuum dust collector

A vacuum suction and fluidization technology, applied in chemical instruments and methods, separation of dispersed particles, filtration of dispersed particles, etc., can solve the problem of increased resistance of the filter bag 3, difficulty in disassembling and replacing the filter bag 3, and failure of the filter bag 3 to be used normally And other problems, to achieve the effect of improving the efficiency of ash suction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

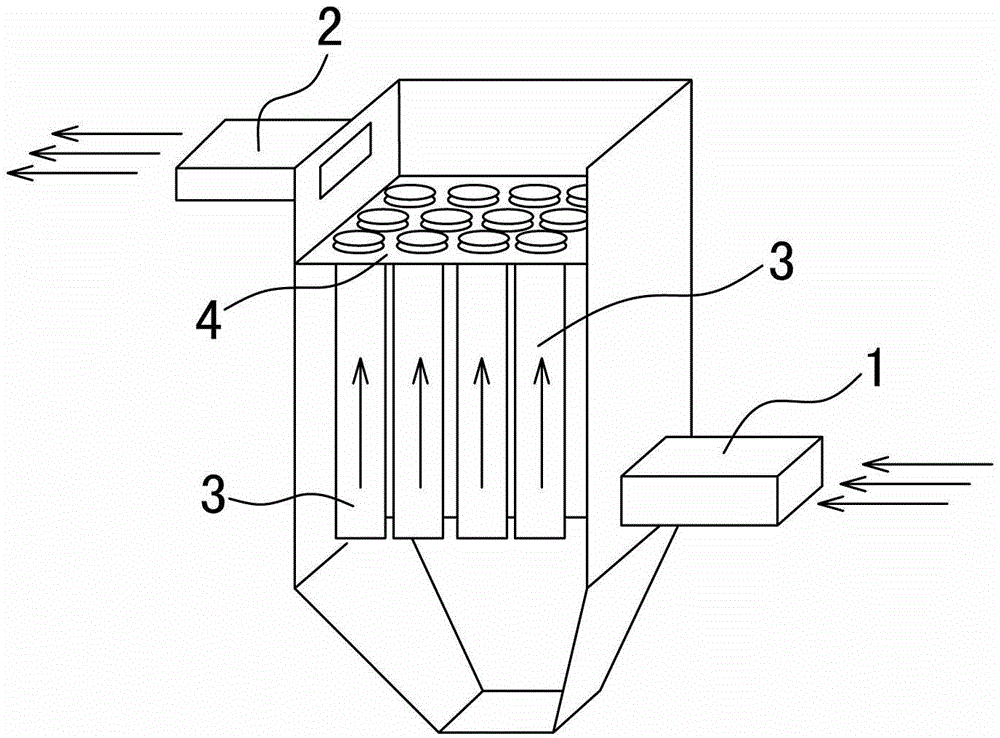

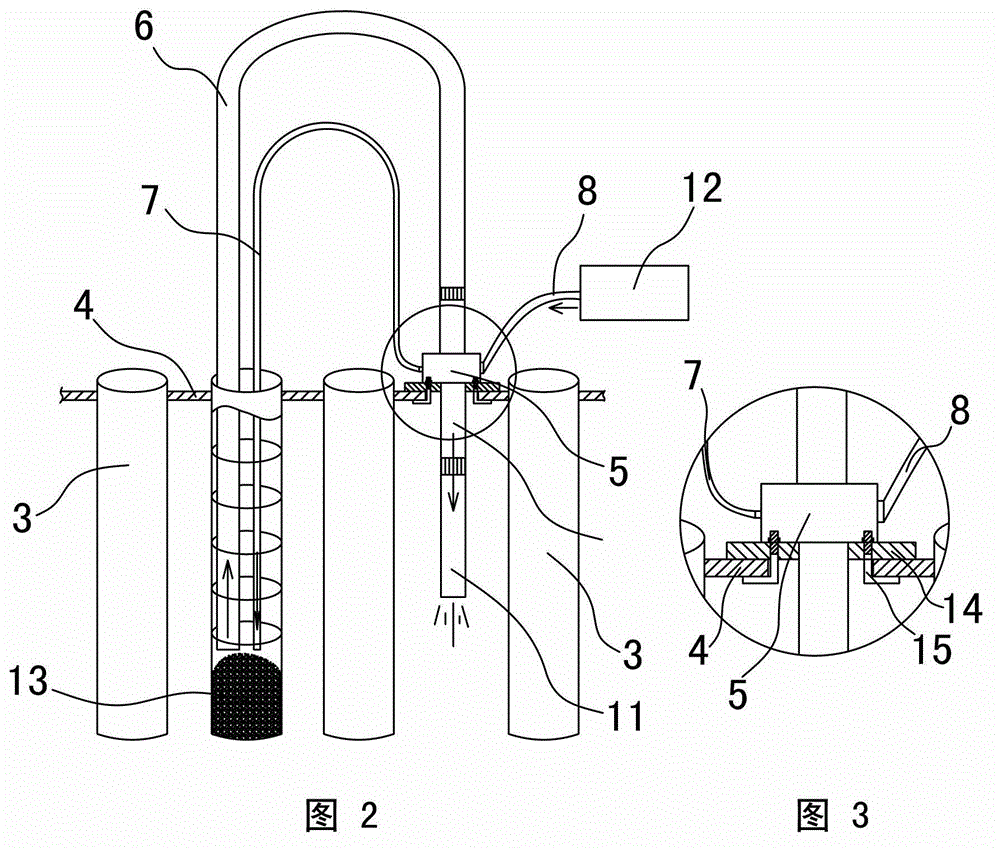

[0029] Example: fluidized vacuum dust collector

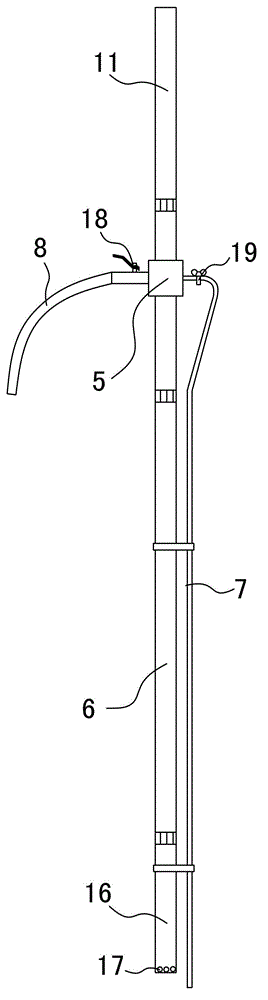

[0030] See attached figure 2 , attached image 3 , attached Figure 4 And attached Figure 5 As shown, a gas distributor 5 is included, an exhaust port 10 and a suction port 9 are provided on the gas distributor 5, and a gas flow connecting the exhaust port 10 and the suction port 9 is provided in the gas distributor 5 channel, an annular air chamber 21 is provided on the outside of the air flow channel along the circumference of the air flow direction, and an annular partition wall 27 is used to separate the annular air chamber 21 and the air flow channel. 11 is threadedly connected, and the suction port 9 is threadedly connected with a dust suction pipe 6. The air inlet pipe 8 is provided with an air inlet valve 18, and the air blow pipe 7 is provided with an air blowing valve 19.

[0031] The air flow passage is composed of a flow equalizing section 25 and a flow converging section 20 along the air flow direction, the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com