Chestnut picking machine

A chestnut machine and guide wheel technology, applied in harvesters, agricultural machinery and implements, applications, etc., can solve problems such as low efficiency and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings:

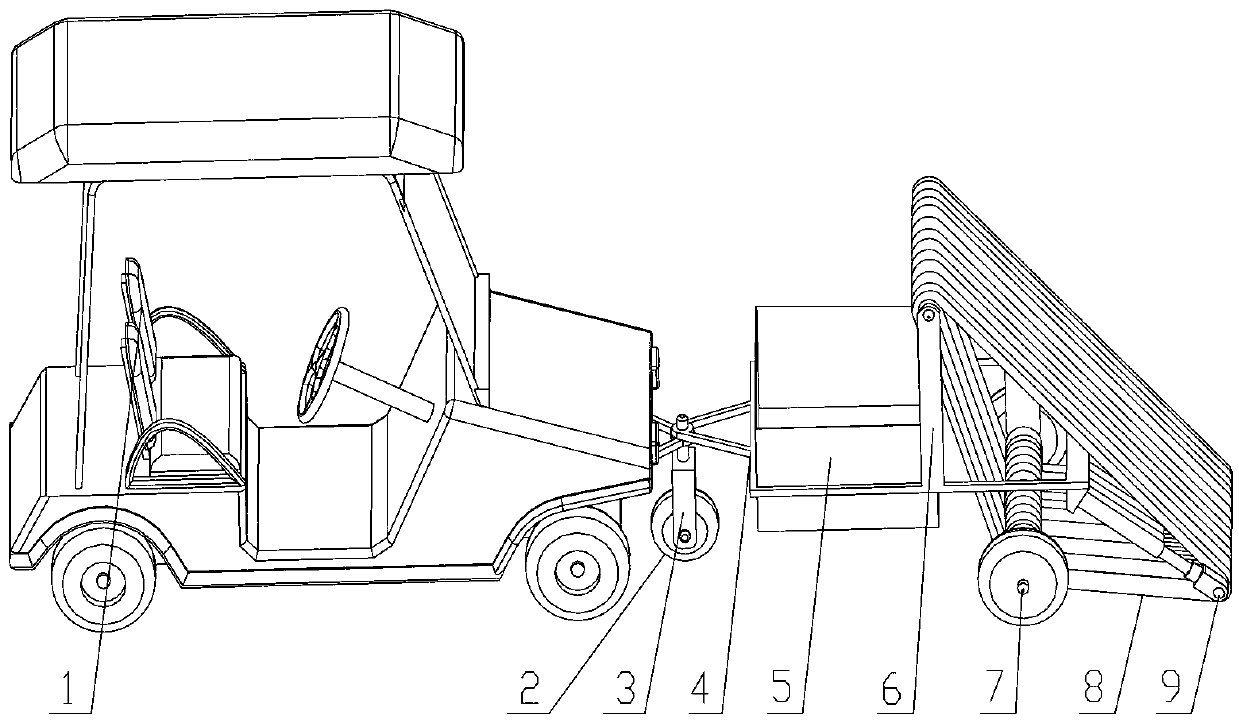

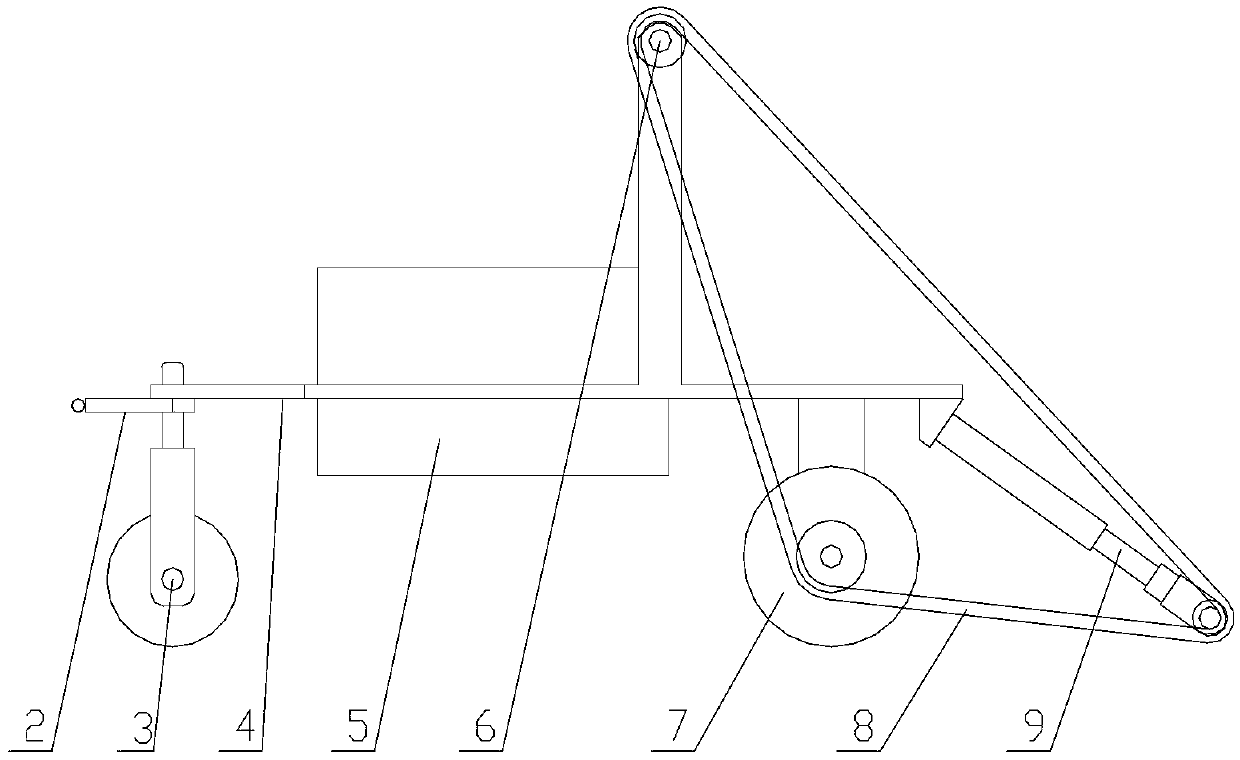

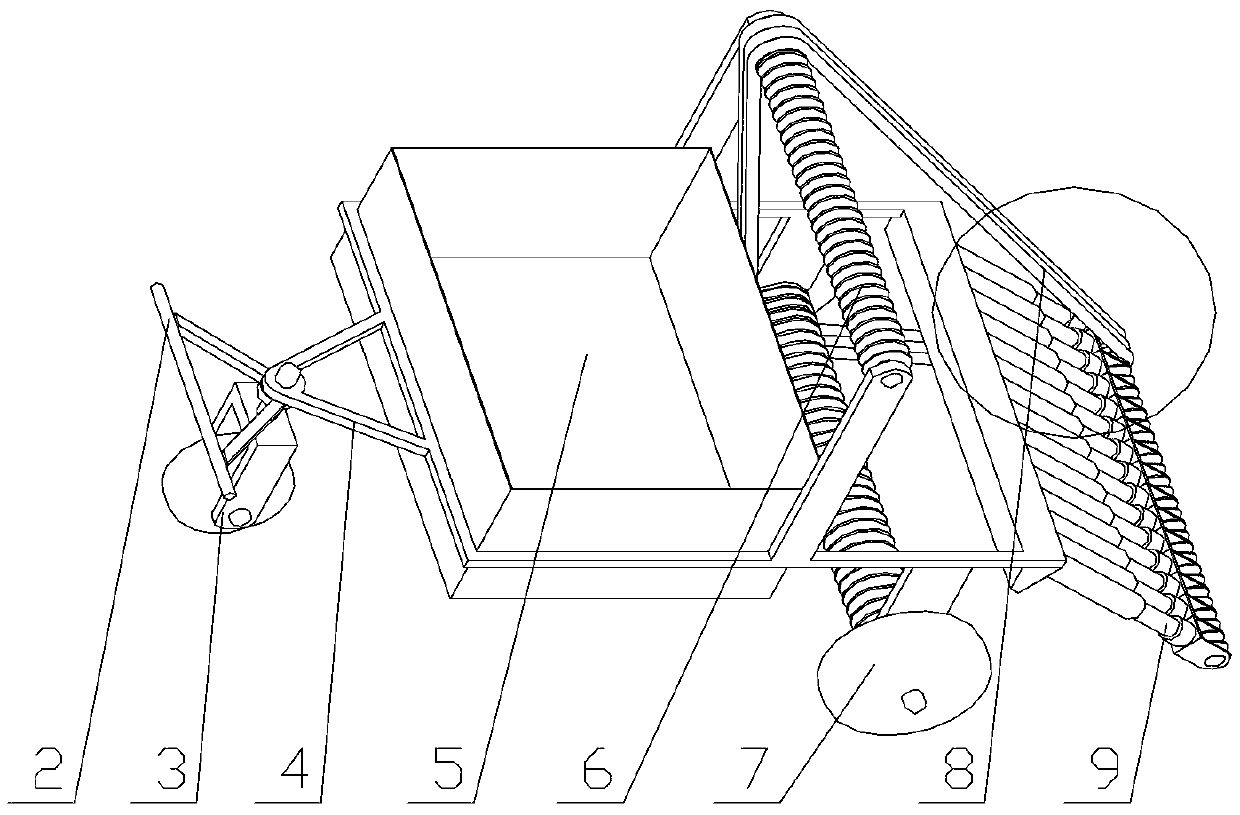

[0019] see Figure 1~4 , the embodiment of the present invention is provided with battery car 1, connector 2, universal wheel 3, skeleton 4, collecting frame 5, guide wheel 6, guide assembly 7, spring group 8 and automatic adjustment guide wheel 9; Described connector 2 is fixed On the battery car 1, a hinge hole is provided on the connecting piece 2, the universal wheel 3 and the frame 4 are hinged with the connecting piece 2, the collection frame 5 is arranged in the rectangular frame of the frame 4, and the bearing seat above the frame 4 passes through the bearing and the frame 4. The guide wheel 6 is connected, the bearing seat located under the frame 4 is connected with the guide assembly 7 through a bearing, the spring seat located on the frame 4 is connected with the automatic adjustment guide wheel 9 through a spring; an arc-shaped guide wheel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com