Lid member with waterproof function, and method of manufacturing thereof

A technology of cover parts and functions, which is applied to the parts of the connection device, manufacturing tools, electrical components, etc., can solve the problem of damage to the coating surface of the connection cover, and achieve the effects of light weight, prevention of peeling, and easy assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Hereinafter, preferred embodiments for carrying out the present invention will be described.

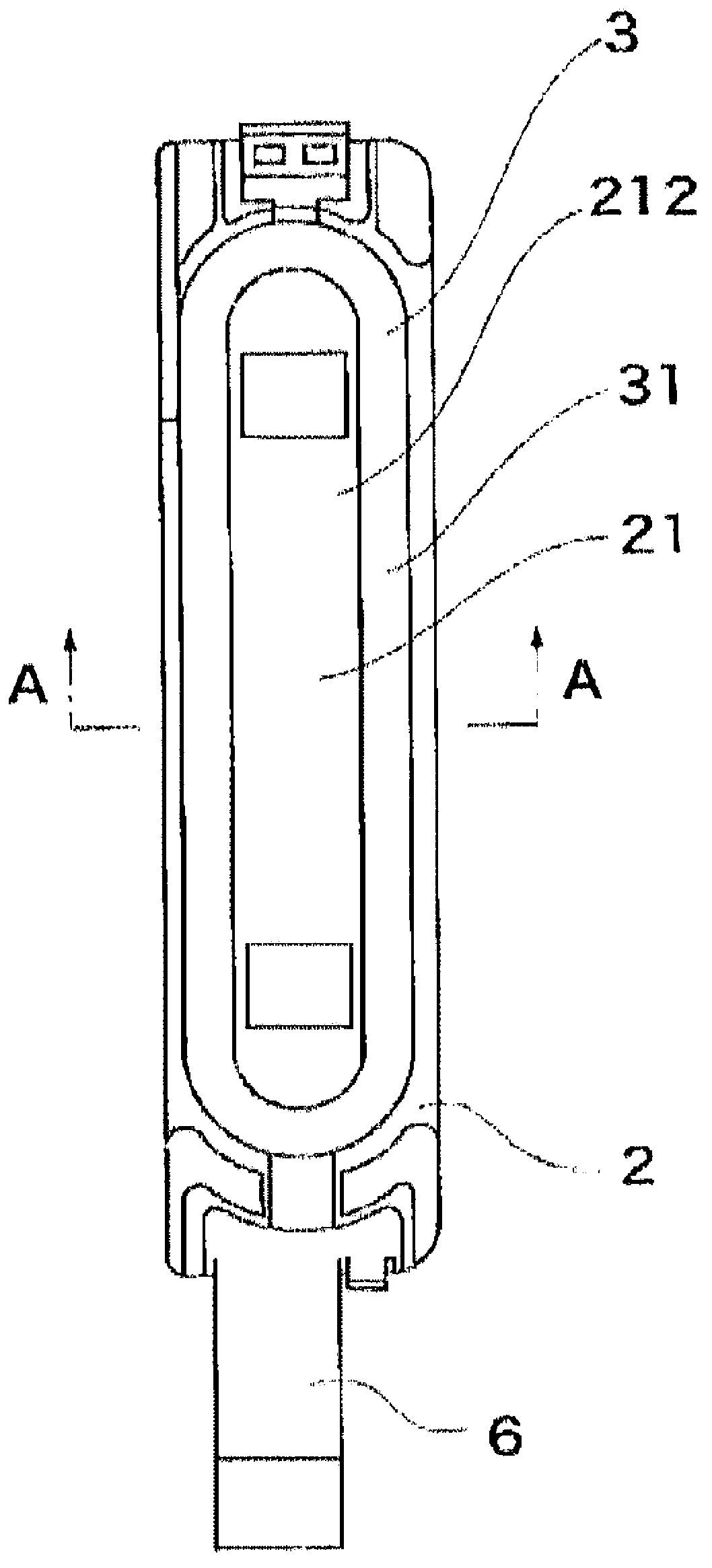

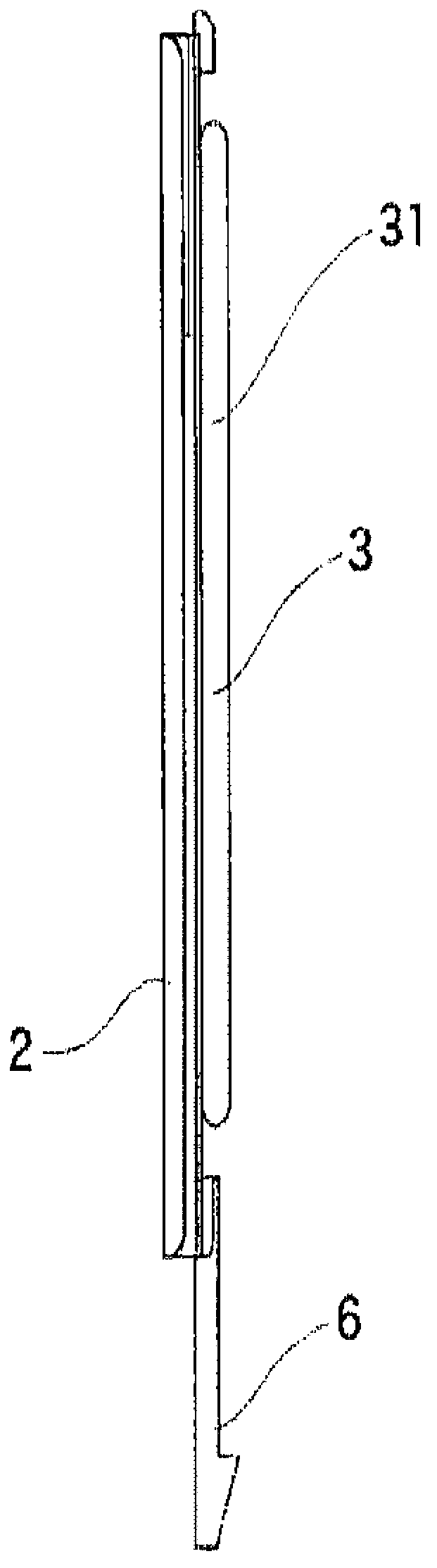

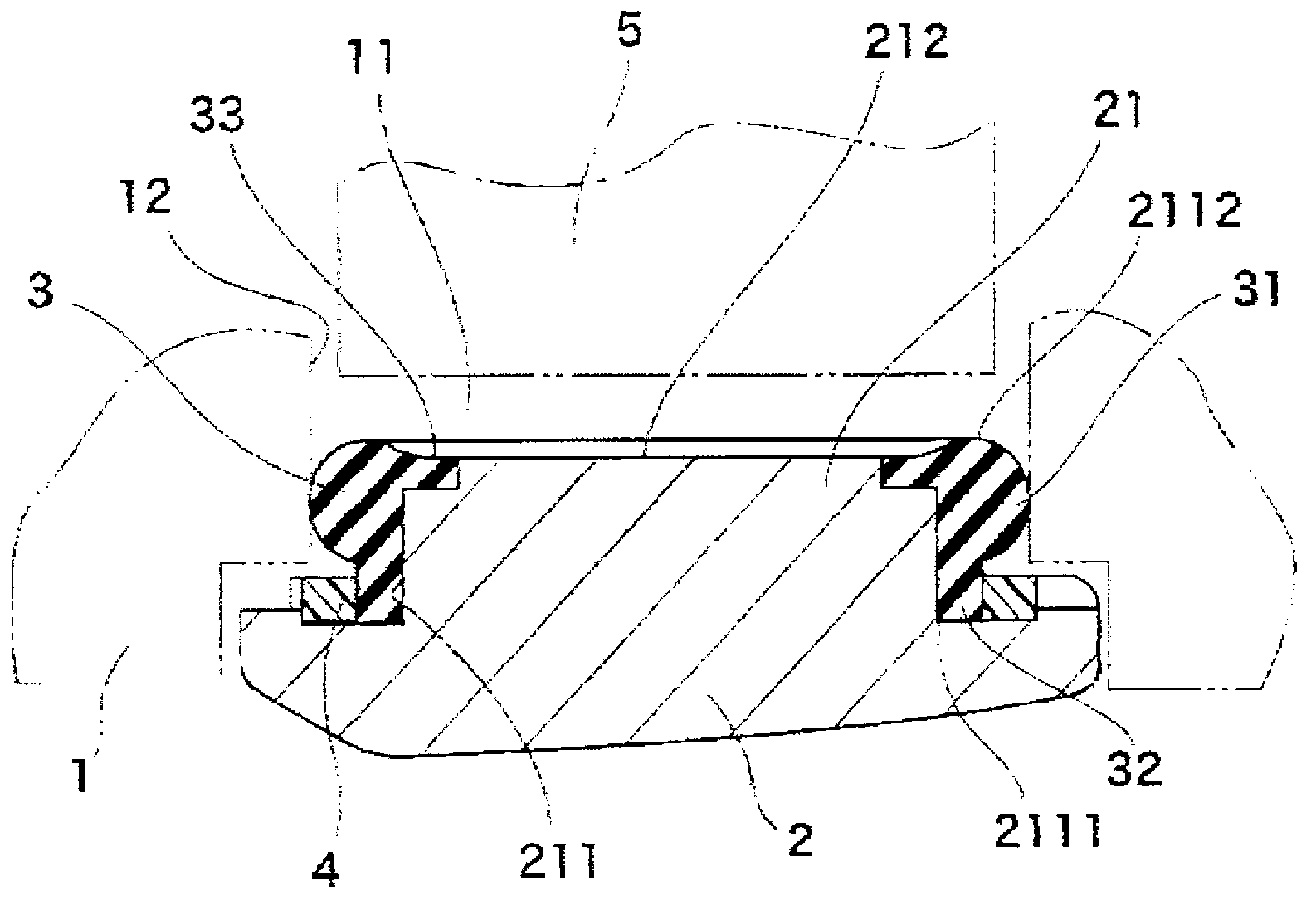

[0052] Such as Figure 1 to Figure 3 As shown, the cover member having a waterproof function according to the present invention is used to open and close the opening 11 formed in the casing 1 forming the housing of the portable terminal device.

[0053] The connector 5 is disposed on the opening 11 .

[0054] In addition, on one side of the main body 2 made of resin material of the cover member, a protrusion 21 , a sealing portion 3 made of a rubber-like elastic material, and a holding portion 4 made of a thermoplastic elastomer material are disposed. The protruding portion 21 is integrally formed on the main body 2 and accommodated in the opening portion 11 . The sealing portion 3 made of rubber-like elastic material is provided with: an annular protrusion 31 integrally formed on the outer peripheral surface 211 of the protrusion 21 and in close contact with the peripheral ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com