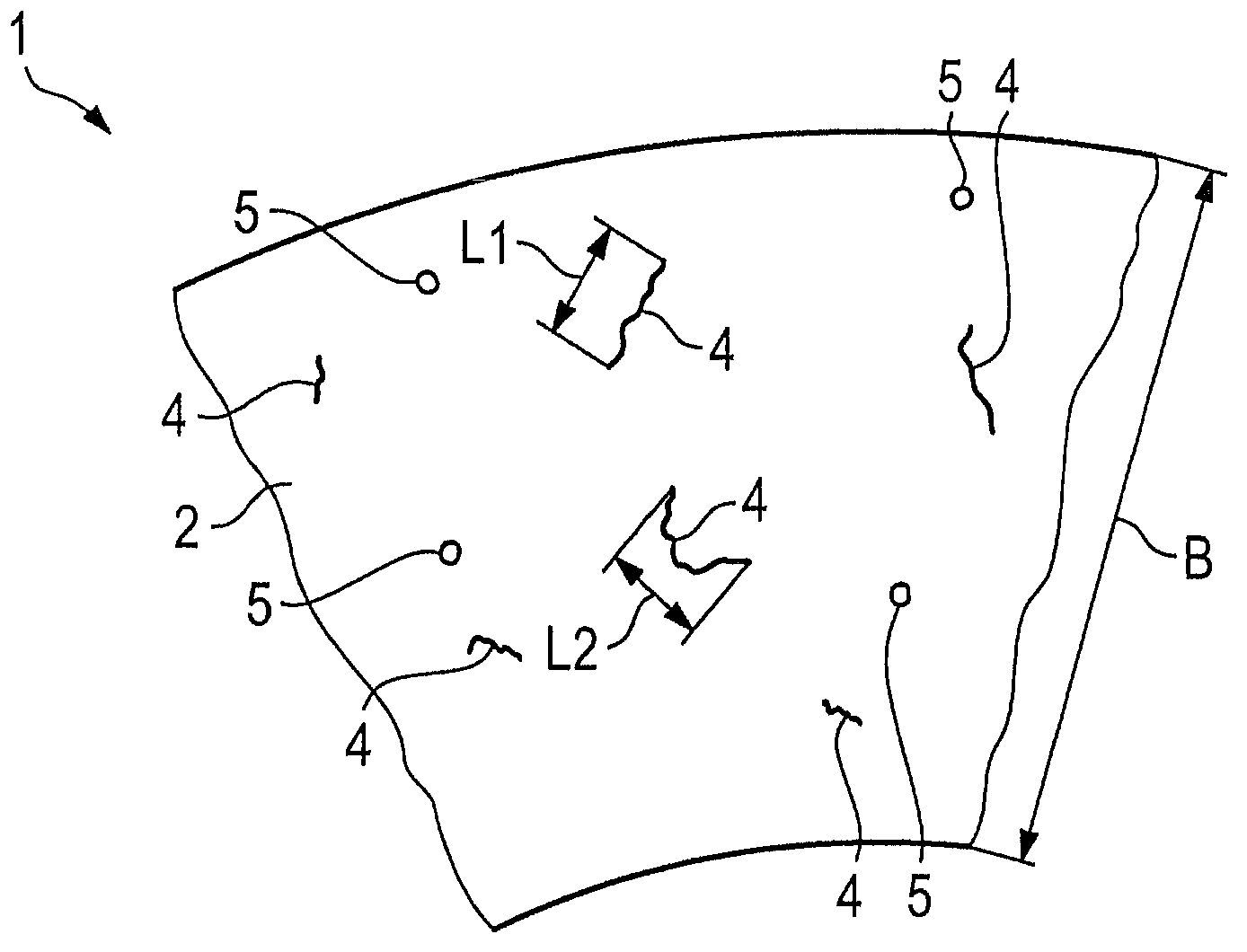

Low-friction sliding ring having an economical diamond coating

A technology of diamond layer and sealing ring, which is applied in engine sealing, metal material coating process, coating, etc., can solve problems such as bad bonding, diamond layer detachment, sealing ring damage, etc., and achieve long service life and excellent dry running The effect of the characteristic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

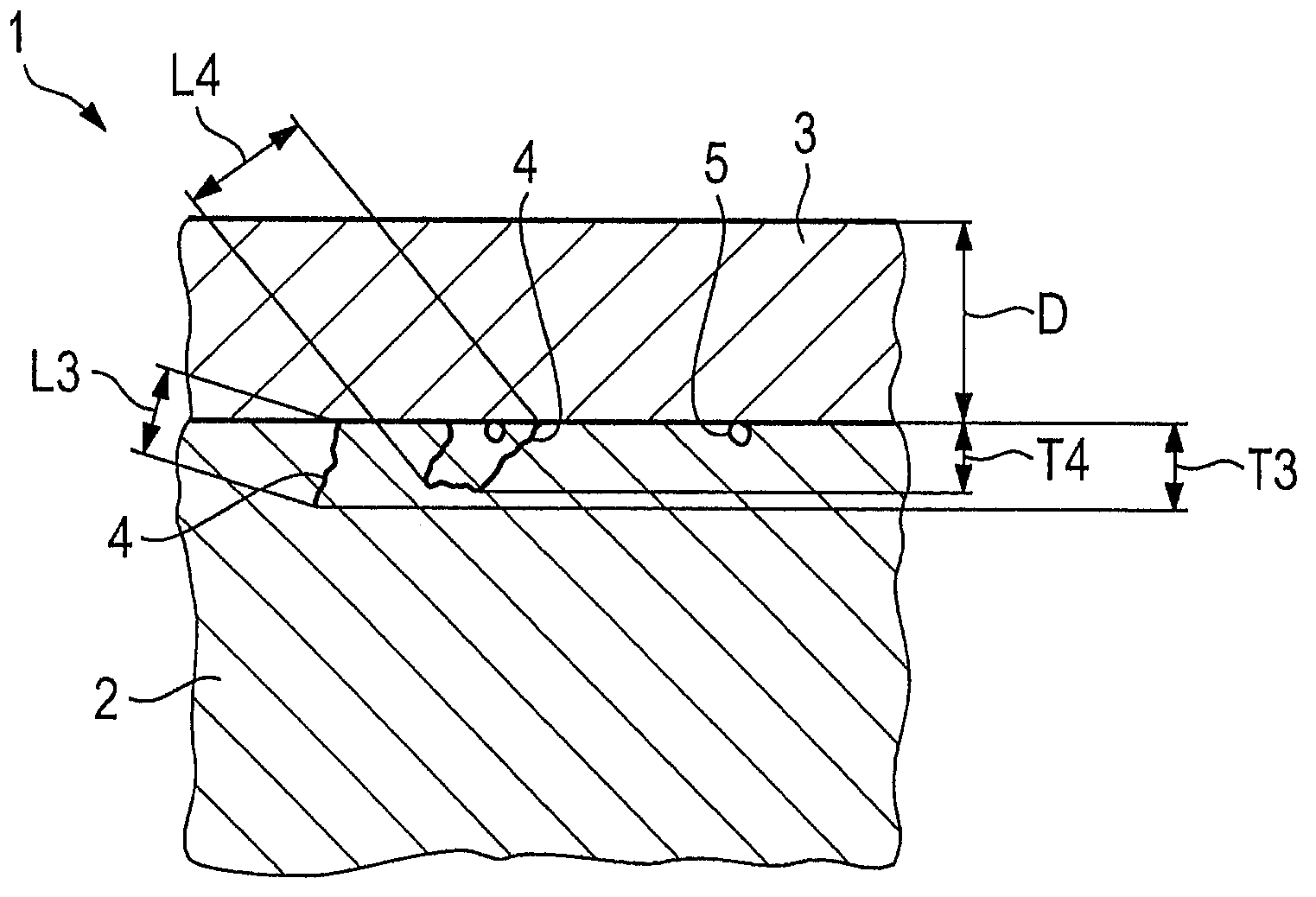

[0030] Here the thickness of the diamond is measured by means of the beta backscattering method. The crystal size was measured by means of an optical microscope with a magnification of 1000 times. Determination of roughness R by means of white light interferometer aAnd the SP3 component was determined by means of Raman spectroscopy. The pore size and pore distance were determined by means of an optical microscope and the slit length and slit depth, respectively, by determining the distribution of the number of slits of ionically inclined cuts (cuts with a minimum cut length of 1 mm) made in the substrate 2 . The hardness of the substrate was determined by means of a Vickers hardness test and the defect specific gravity, defined as the area ratio of uncoated defects on the surface of the substrate to the diamond-applied surface, was determined by means of an optical microscope.

[0031] Therefore, according to the present invention, a uniform and permanent diamond coat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com