MWT solar battery and manufacturing method thereof

A technology for solar cells and substrates, applied in circuits, electrical components, and final product manufacturing, etc., can solve the problems of complex process flow, high cost of removing the back field, and achieve the effect of simple process, cost control, and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Hereinafter, the present invention will be described in detail with reference to the drawings and examples. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

[0020] Explanation of terms:

[0021] MWT: Metal Emitter Wrap Through Hole Technology.

[0022] Double-sided power generation battery: The front and back of the battery are designed with main grid and fine grid, so that the back of the battery can also absorb light and improve the utilization rate of light.

[0023] Back field (diffusion back field): On the back side of the silicon wafer (the side where the pn junction is not formed), a high-low junction is formed through diffusion, that is, the back field.

[0024] Strong alkaline solution: an alkaline solution that can completely ionize in water and release hydroxide ions.

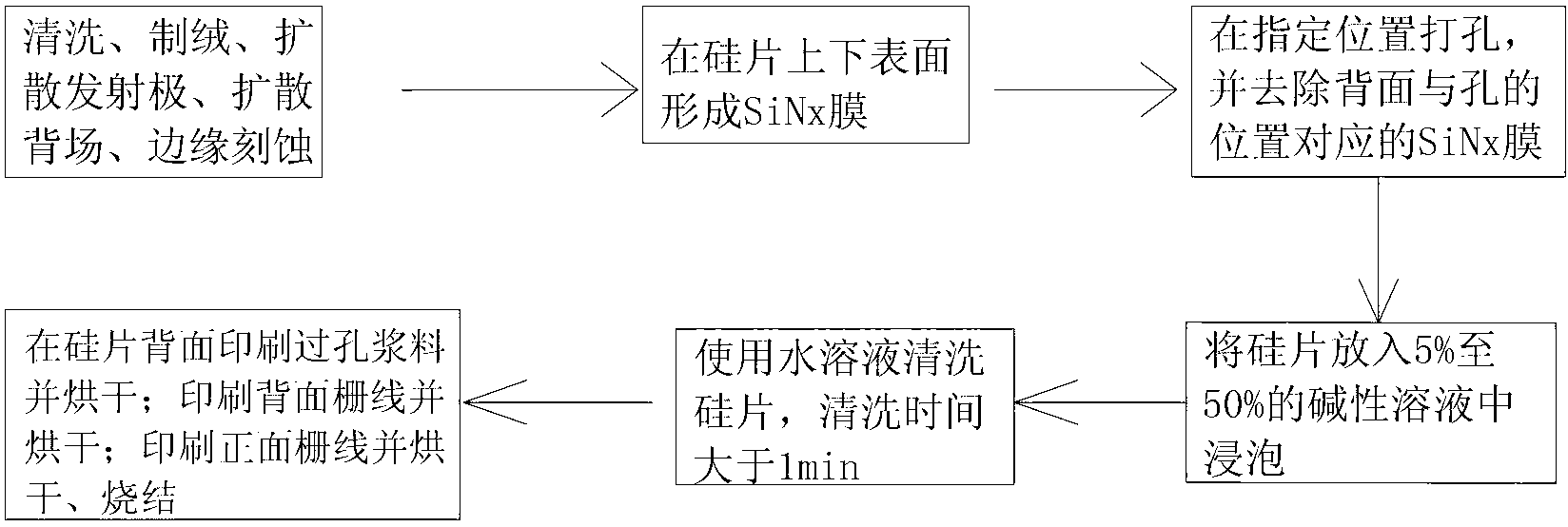

[0025] Such as figure 1 As shown, according to an embodiment of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com