Light wood construction side-froce-resistance design rigid membrane sheet model and application

A wooden structure and membrane technology, applied in teaching models, educational tools, instruments, etc., can solve the problems of lack of anti-side design structural models, and achieve the effect of avoiding design defects and simplifying the design process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

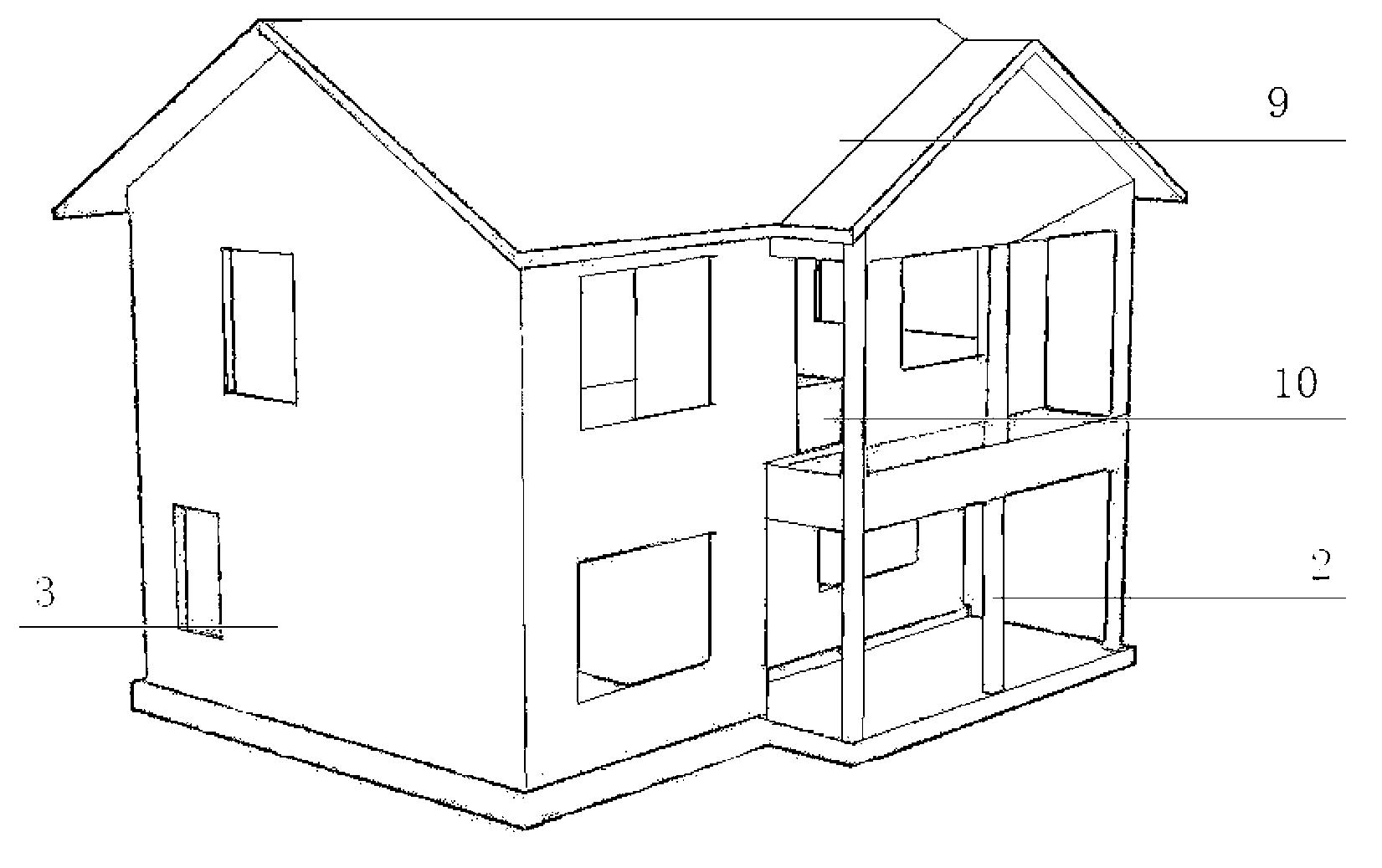

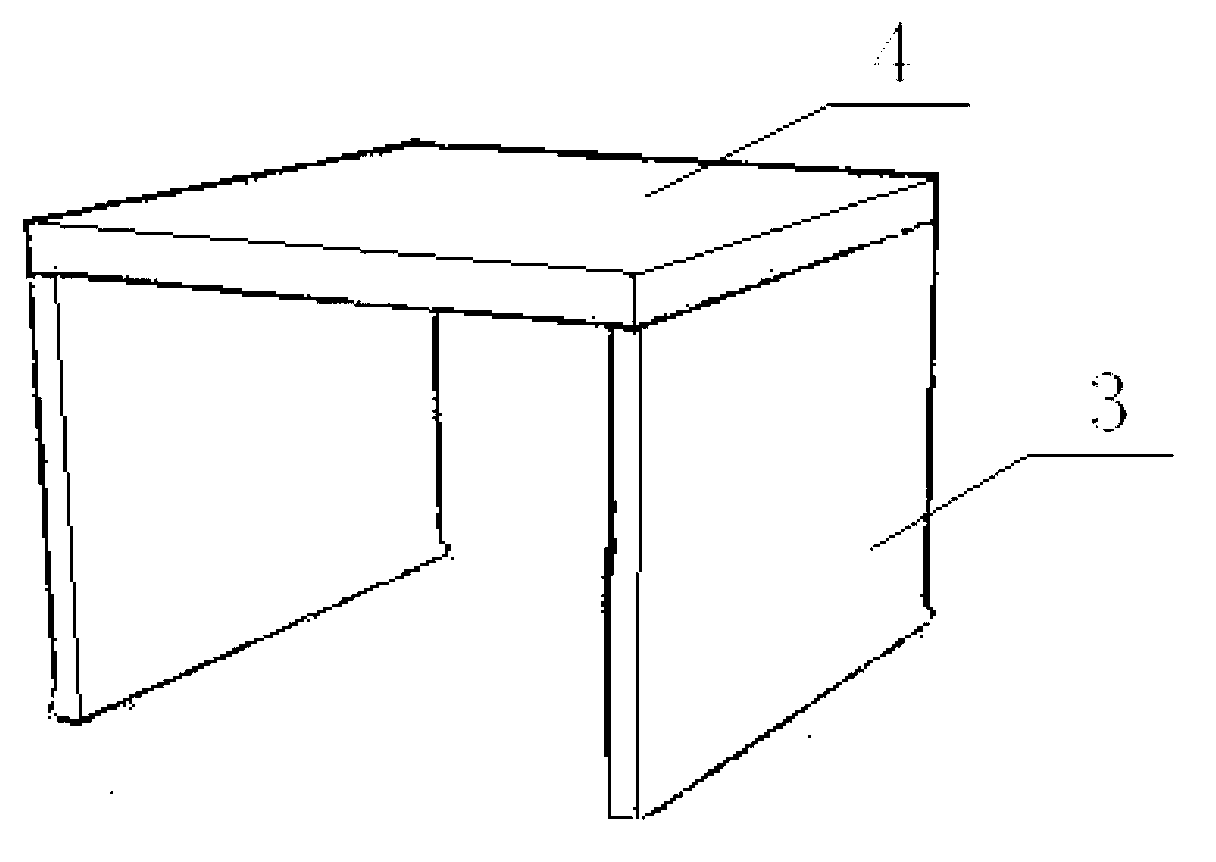

[0044] Embodiment 1: A kind of rigid diaphragm model of light timber structure anti-side design (see Figure 1-5 ), characterized in that it consists of a rigid diaphragm and a frame column 2, the rigid diaphragm 2 is divided into a horizontal rigid sheet 4 and a vertical rigid sheet 3, and the horizontal rigid sheet 4, the vertical rigid sheet 3 and the frame column 2 are respectively Combined into a simply supported rigid sheet member unit, a cantilevered rigid sheet member unit and a torsion rigid sheet member unit, the simply supported rigid sheet member unit, the cantilevered rigid sheet member unit and the torsion rigid sheet member unit are composed of horizontal The arrangement and combination of horizontal and vertical and vertical and vertical constitute the whole model.

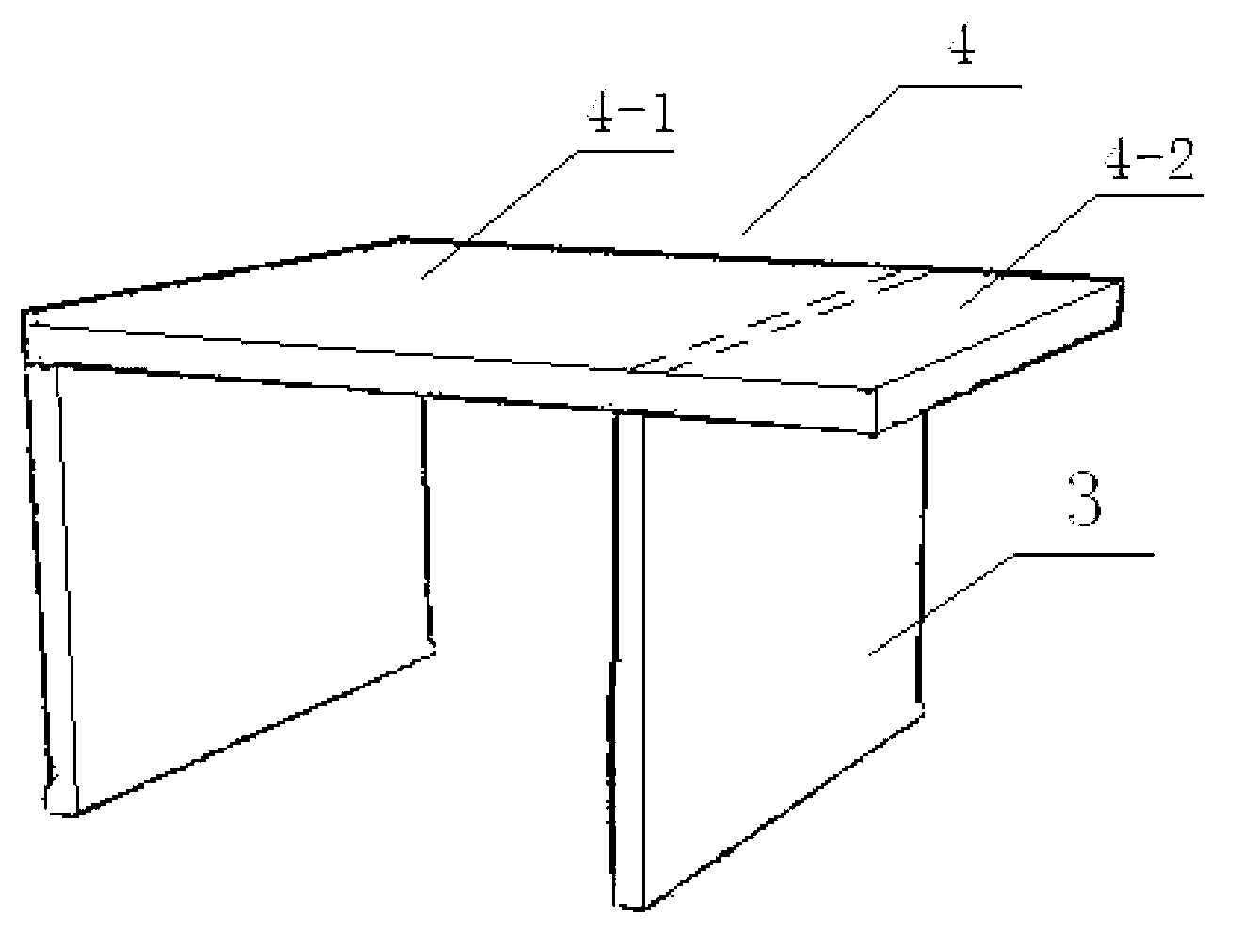

[0045]The above-mentioned rigid diaphragm is composed of a diaphragm 5, an in-membrane strut 6 and an edge strut 7, and the in-mold strut 6 and the edge strut 7 are fixedly connected to the diaphra...

Embodiment 2

[0070] Embodiment 2: a kind of rigid diaphragm model of light wood structure anti-side design, it is characterized in that it is made of rigid diaphragm and frame column 2, and rigid diaphragm 2 is divided into horizontal rigid sheet 4 and vertical rigid sheet 3, described The horizontal rigid sheet 4, the vertical rigid sheet 3 and the frame column 2 are respectively combined into a simply supported rigid sheet member unit, a cantilevered rigid sheet member unit and a torsional rigid sheet member unit. The whole model is composed of horizontal and horizontal, horizontal and vertical, vertical and vertical arrangement and combination between component unit and torsion rigid sheet component unit.

[0071] The above-mentioned rigid diaphragm is composed of a diaphragm 5, an in-membrane strut 6 and an edge strut 7, and the in-mold strut 6 and the edge strut 7 are fixedly connected to the diaphragm 5 through structural nails 8, and the edge strut The rods 7 are fixed on the edge o...

Embodiment 3

[0096]Embodiment 3: a kind of rigid diaphragm model of anti-side design of light wood structure is characterized in that it is made of rigid diaphragm and frame column 2, and rigid diaphragm 2 is divided into horizontal rigid sheet 4 and vertical rigid sheet 3, described The horizontal rigid sheet 4, the vertical rigid sheet 3 and the frame column 2 are respectively combined into a simply supported rigid sheet member unit, a cantilevered rigid sheet member unit and a torsional rigid sheet member unit. The whole model is composed of horizontal and horizontal, horizontal and vertical, vertical and vertical arrangement and combination between component unit and torsion rigid sheet component unit.

[0097] The above-mentioned rigid diaphragm is composed of a diaphragm 5, an in-membrane strut 6 and an edge strut 7, and the in-mold strut 6 and the edge strut 7 are fixedly connected to the diaphragm 5 through structural nails 8, and the edge strut The rods 7 are fixed on the edge of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com