burners for gas hobs

A technology for burners and gas stoves, which is applied in the direction of gas fuel burners, burners, and combustion methods. It can solve the problems of short mixing time and mixing path, unfavorable full combustion of gas, and insufficient combustion of yellow flames, so as to avoid burning Insufficient, long mixing time, the effect of improving the mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

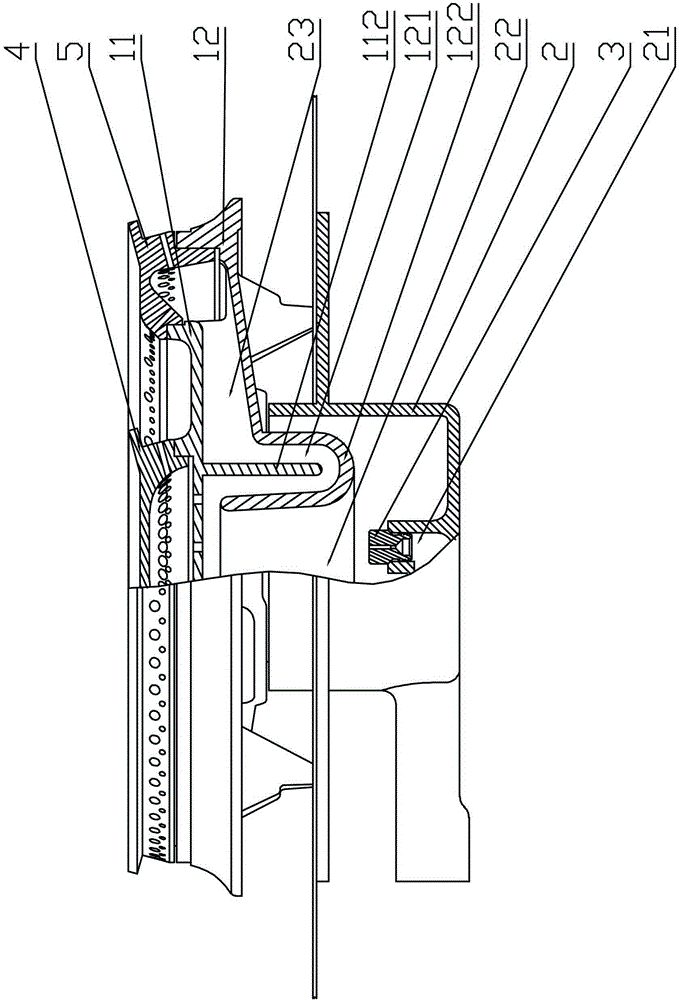

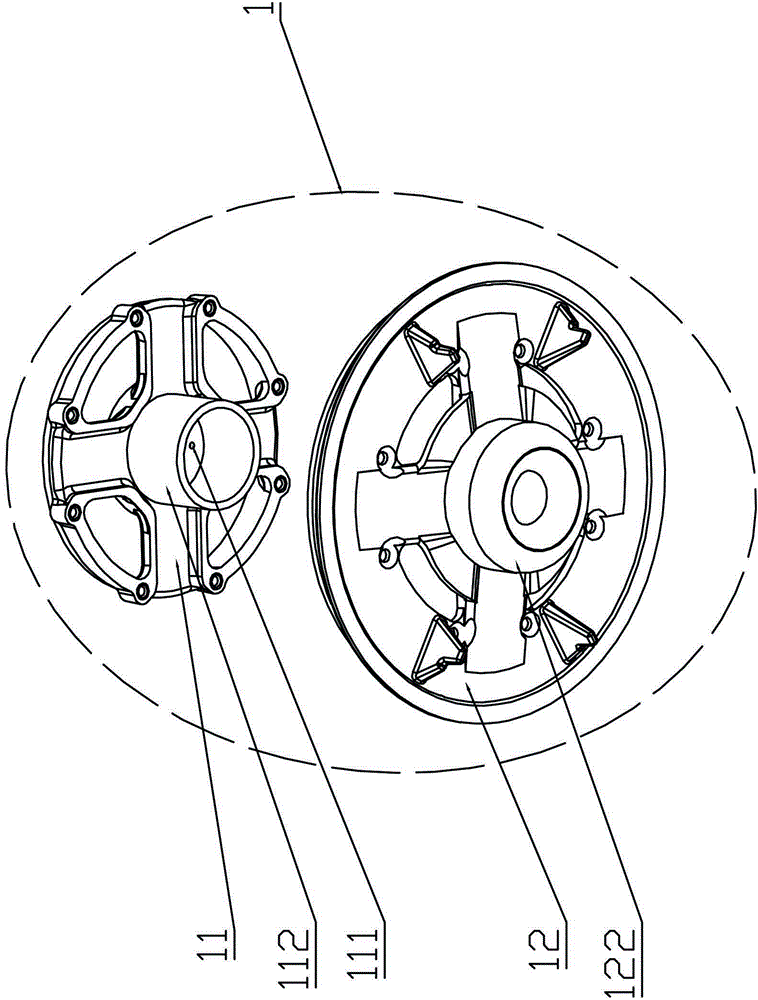

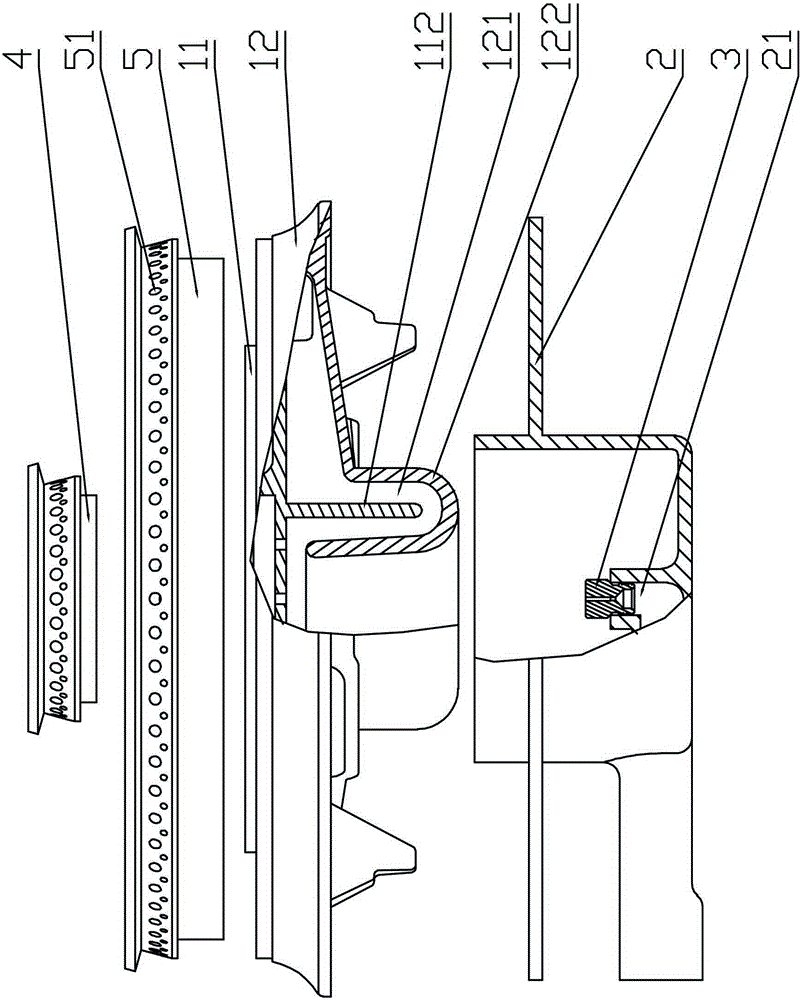

[0023] Specific implementation method: see attached figure 1 , attached figure 2 , attached image 3 , attached Figure 4 , attached Figure 5 , attached Figure 6 , attached Figure 7 As shown, the present embodiment includes an upper seat 1, a lower seat 2, a nozzle 3, a central fire distribution device 4, and an outer ring fire distribution device 5. The injection cavity 22 and the mixing cavity 23, the injection cavity 22 is located above the nozzle 3, the upper seat 1 includes the upper seat top plate 11 and the upper seat bottom plate 12, the upper seat top plate 11 and the upper seat bottom plate 12 can be connected by riveting or screw connection to form a complete upper seat 1 . as attached Figure 4 As shown, the upper seat top plate 11 is covered on the upper seat bottom plate 12 to form a "U" type mixing channel 121, as attached Figure 5 As shown, the upper seat top plate 11 covers the upper seat bottom plate 12 to form a "W"-shaped mixing channel 121, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com