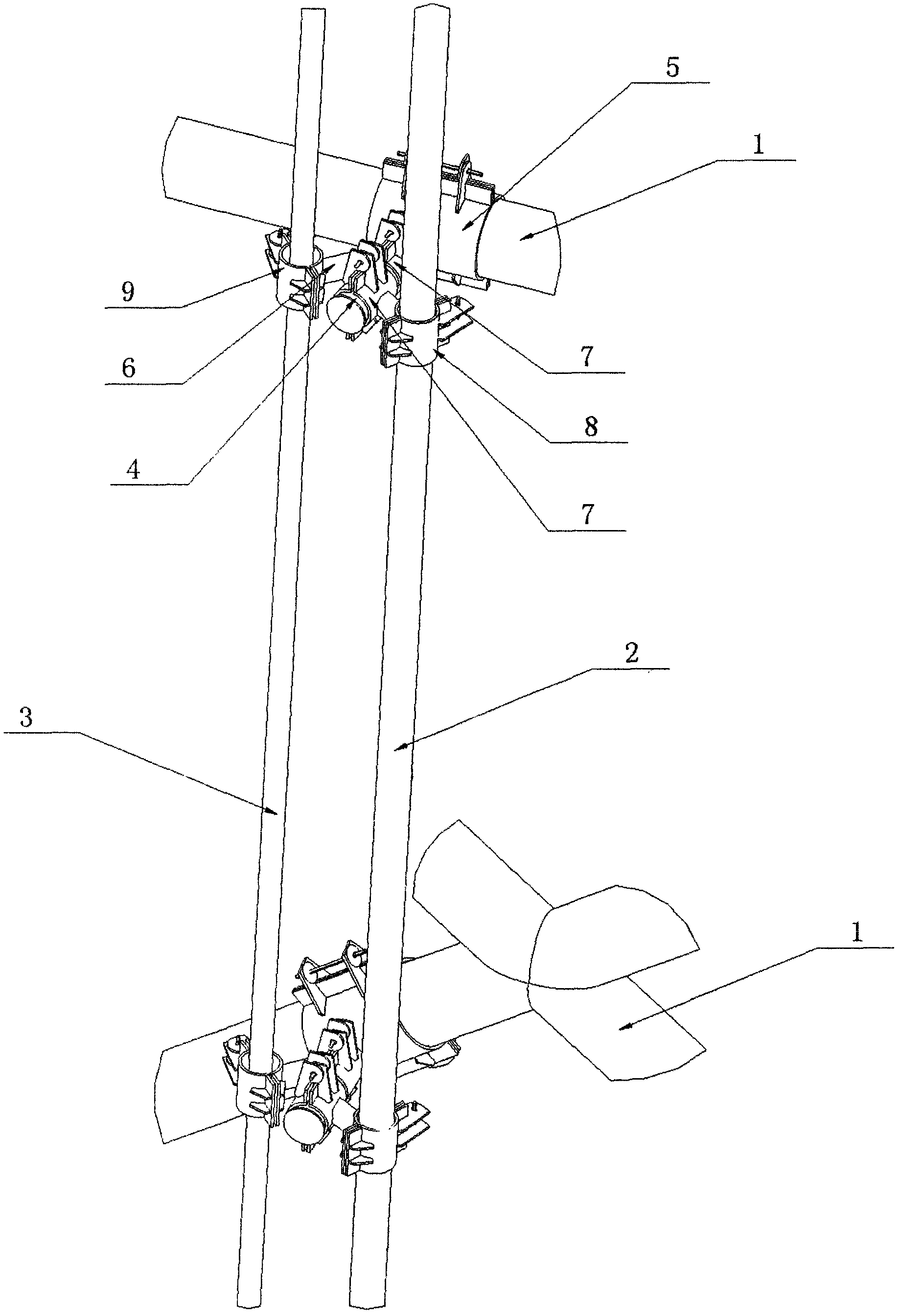

Adjustable underwater pipe clamp device

An adjustable, pipe-clamping technology, applied in the directions of underwater structures, hoses, pipes, etc., can solve the problems of difficult implementation, narrow construction space for blocks, and tight spare space for jacket structure rods, and reduce installation costs. , The effect of improving the success rate of offshore installation and shortening the offshore construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] 1. The design of the underwater combined pipe clamp. Firstly, according to the structure diagram of the jacket, the layout diagram of the newly established pipe and the cable protection pipe, the stakeout is carried out to determine the installation position of the main pipe clamp on each horizontal layer of the jacket. According to the load conditions of the platform wave environment, the structural strength design of the pipe clamp is carried out, and the type of locking bolt is selected according to the calculation results.

[0011] 2. Manufacture of underwater combined pipe clips. Due to the high precision requirements of offshore installation, the factory will strictly control the size of the pipe clamps according to the design drawings, and has the ability to temporarily correct the local dimensions of the pipe clamps.

[0012] 3. Pre-measurement of the underwater size of the jacket. Through an accurate underwater inspection, find out the specific conditions suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com