Frame wall pile type wharf

A frame and wharf technology, applied in the field of frame wall pile type wharf, can solve problems such as low bearing capacity, increased construction difficulty, poor durability, etc., and achieve strong foundation adaptability, high component prefabrication, and less sand and gravel consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

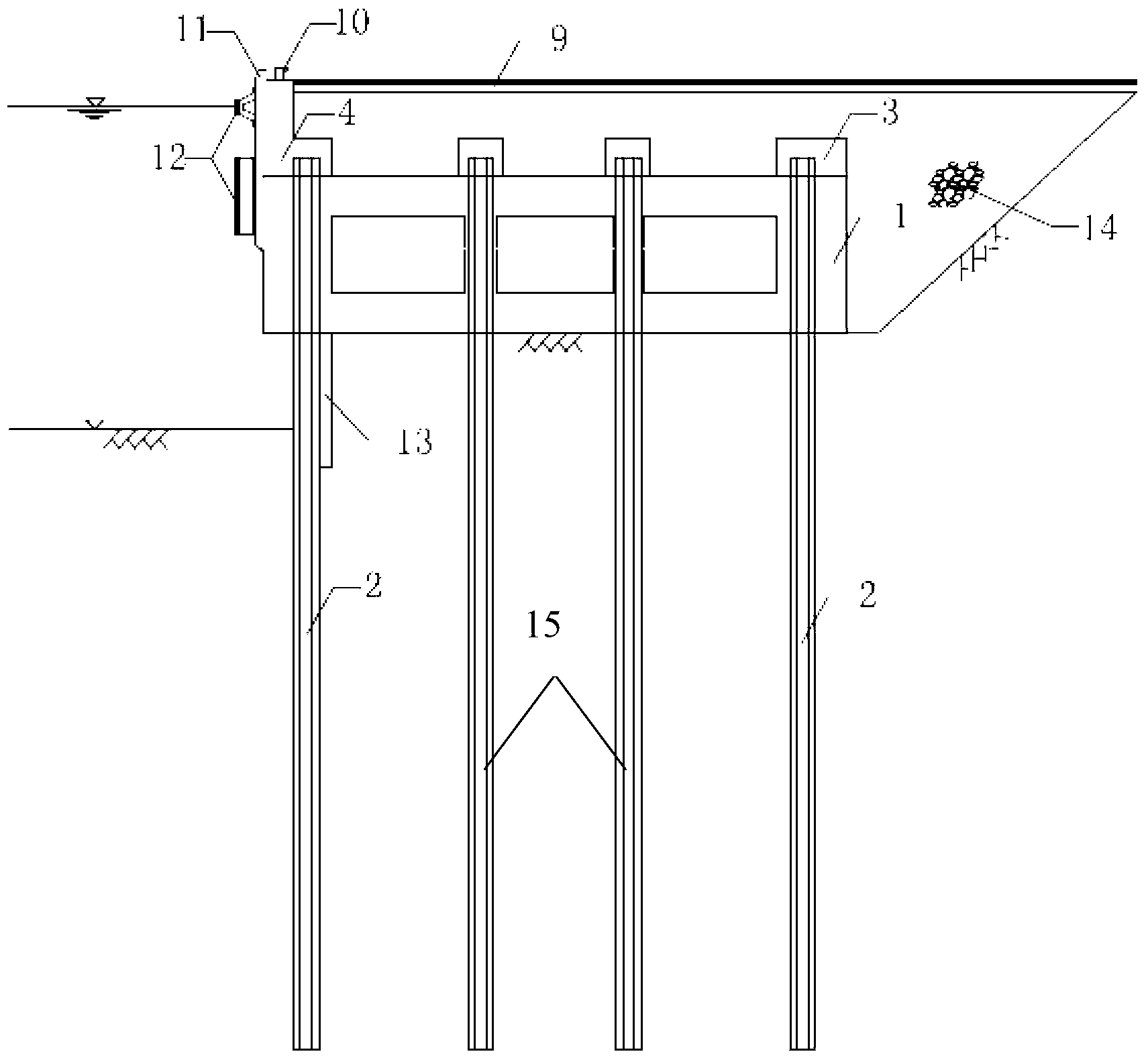

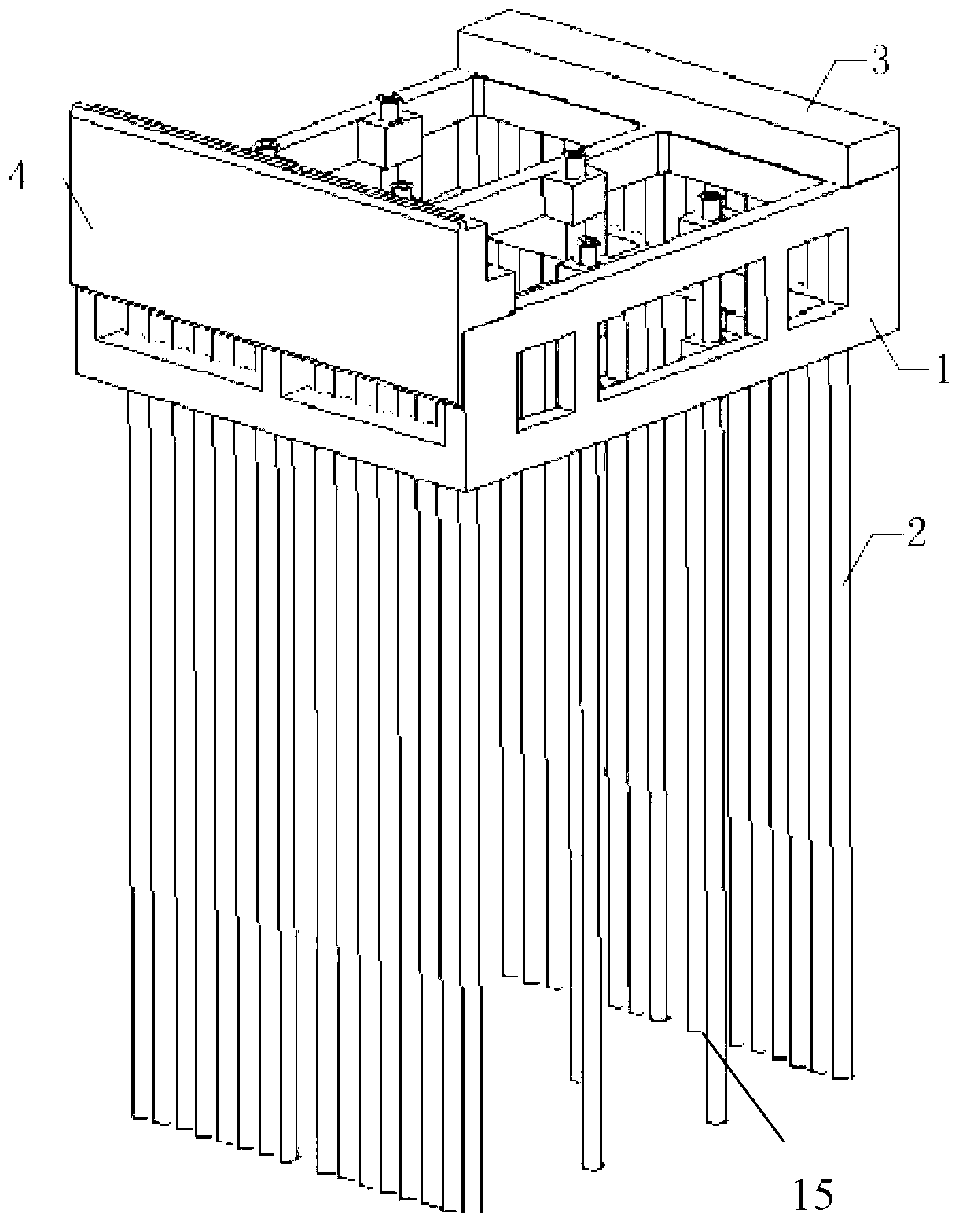

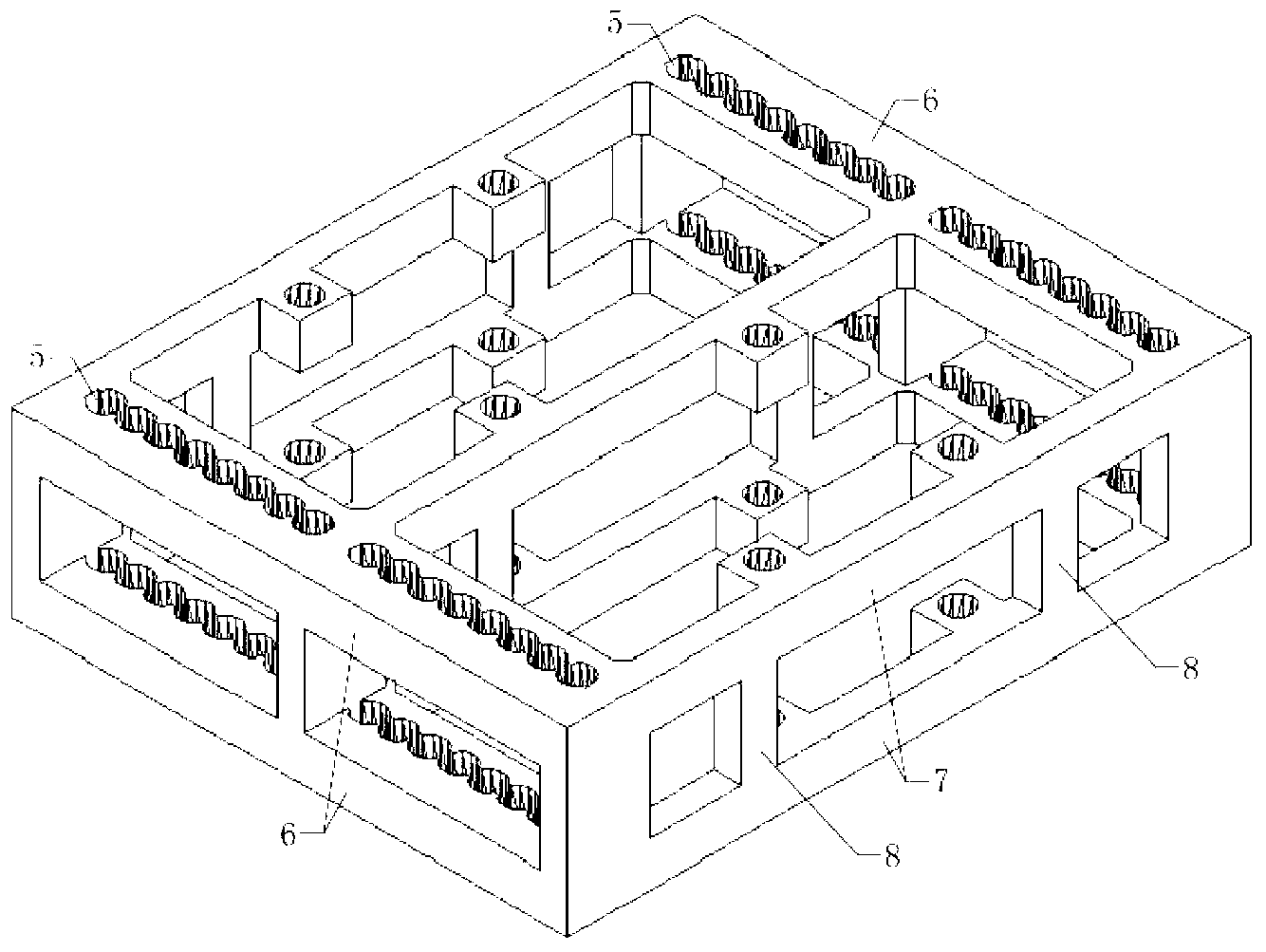

[0040] Such as figure 1 As shown, the top surface elevation of the frame wall piled wharf is 5m, the elevation of the original mud surface is -1.5m, the elevation of the excavated mud surface is -4.5m, the design high water level is 4.3m, and the design low water level is 0.5m. The wall piles are PHC pipe piles with a pile diameter of 600mm, a wall thickness of 130mm and a pile length of 23m. The precast concrete frame is 15m long, 12.2m wide and 4m high. The wharf is designed with a ground load of 100kPa / m 2 .

[0041] 1. Geological data

[0042] The geological parameters are selected from the ZK2 drill hole in the "Geological Survey of Beidawei Nian Dike Engineering Geological Survey in Dongjiang Port Area, Tianjin Port":

[0043] Table 1-1 Soil physical and mechanical indicators

[0044]

[0045]

[0046] 2. Calculation of internal force of pile and frame structure

[0047] According to the calculation of the depth of the BZ, combined with the geological bearing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com