Carbonization treatment process and device thereof of animals died of illness

A treatment process, animal charcoal technology, applied in the petroleum industry, special carbonization, coke oven, etc., can solve the problems of high power consumption, inconvenient operation, heavy labor, etc., to reduce floor space and maintenance cost, heat loss reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

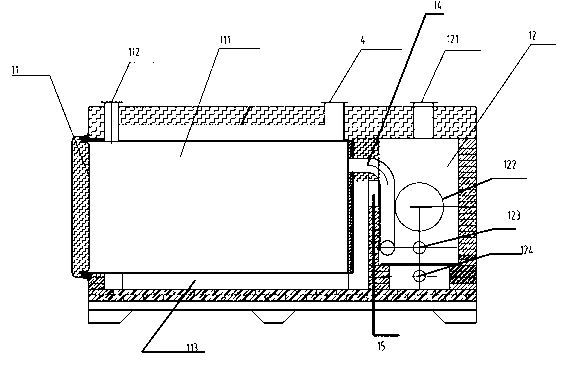

Image

Examples

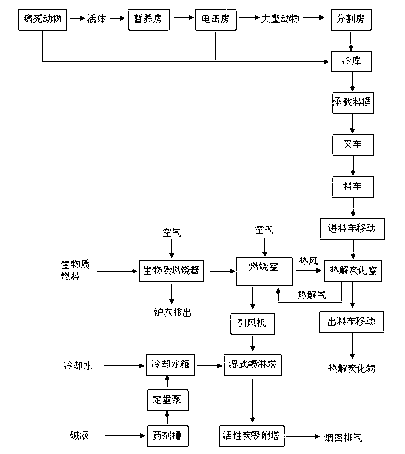

Embodiment 1

[0071] like image 3 As shown, for the diseased pigs seized by the agricultural department or handed over by farmers, if they are dead, the carcasses are directly unloaded into the cold storage for temporary storage; for live pigs, they are first unloaded to the temporary breeding workshop, and then sent to the cold storage for temporary storage after being killed by electric shock. live. When the number of dead animals is too large to be immediately pyrolyzed and carbonized, they can be frozen and temporarily stored to reduce environmental pollution and worker operability, making the treatment process safer and more environmentally friendly.

[0072] The carrying mechanism is a material frame, the transfer mechanism is a forklift, the transfer track is a material truck guide rail; the automatic conveying mechanism is a material truck. The diseased and dead animals to be treated are first sent to the stacking platform of the treatment workshop, and the corpses are stacked in ...

Embodiment 2

[0081] Same as Example 1, the difference is that the carcasses of dead animals such as chickens and ducks are subjected to pyrolysis and carbonization treatment at a temperature of 300°C under oxygen barrier and normal pressure, and the flue gas produced by pyrolysis and carbonization is burned at 800°C; The material fuel is the carbonized product produced by the carbonization process of sick and dead animals. The combustion time of the flue gas generated in the pyrolysis and carbonization process in the combustion chamber is 1s. The combusted flue gas is cooled in the sodium hydroxide alkali solution in the wet spray tower 51 at a cooling rate of 500°C / s. The flue gas is quenched in an alkaline solution, which helps to prevent the generation of harmful gases such as dioxins.

Embodiment 3

[0083] Same as Example 1, the difference is that the dead animal carcasses such as cattle are dried and pyrolytically carbonized at a temperature of 600° C. under oxygen barrier and normal pressure, and the smoke generated by pyrolytic carbonization is burned at 1300° C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com