Low-temperature vehicle-mounted oil drilling fluid purifying system during drilling and repairing

A purification system and oil drilling technology, applied in wellbore/well components, earthwork drilling, flushing wellbore, etc., can solve problems such as focusing on system pipelines and local ingredients, no function of removing iron filings, scattered layout, etc., to achieve It is convenient for the collection and treatment of waste solid phase, meets the requirements of vehicle transportation, and solves the effect of installation problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further elaborated below in conjunction with the accompanying drawings.

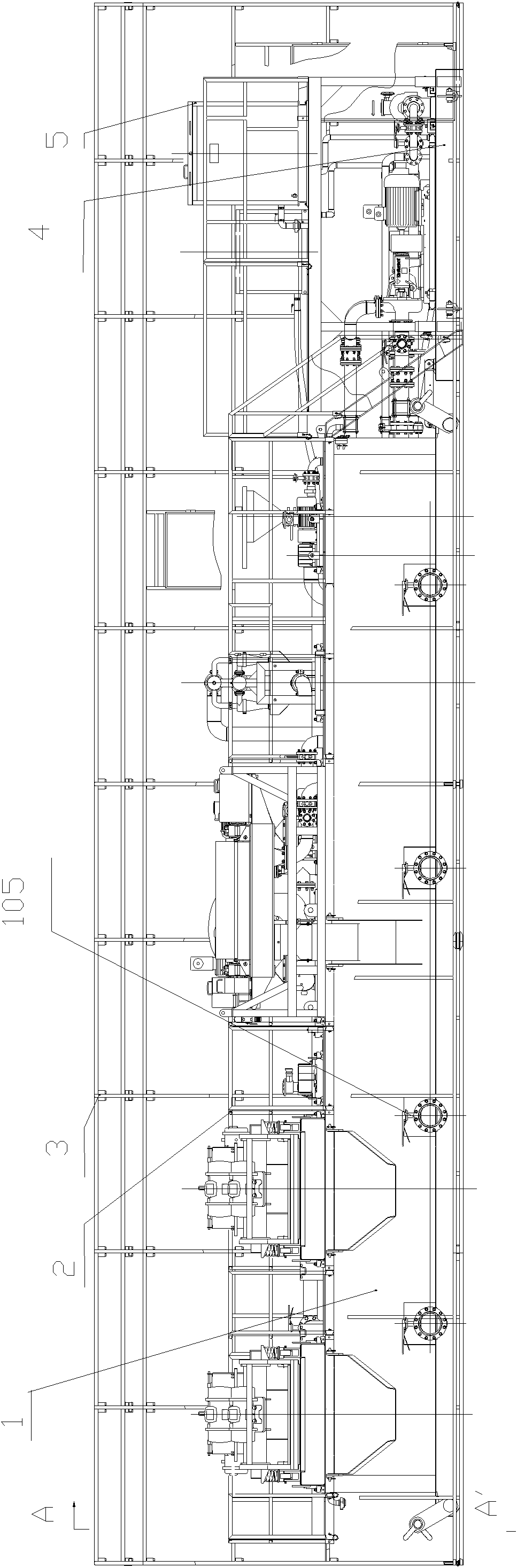

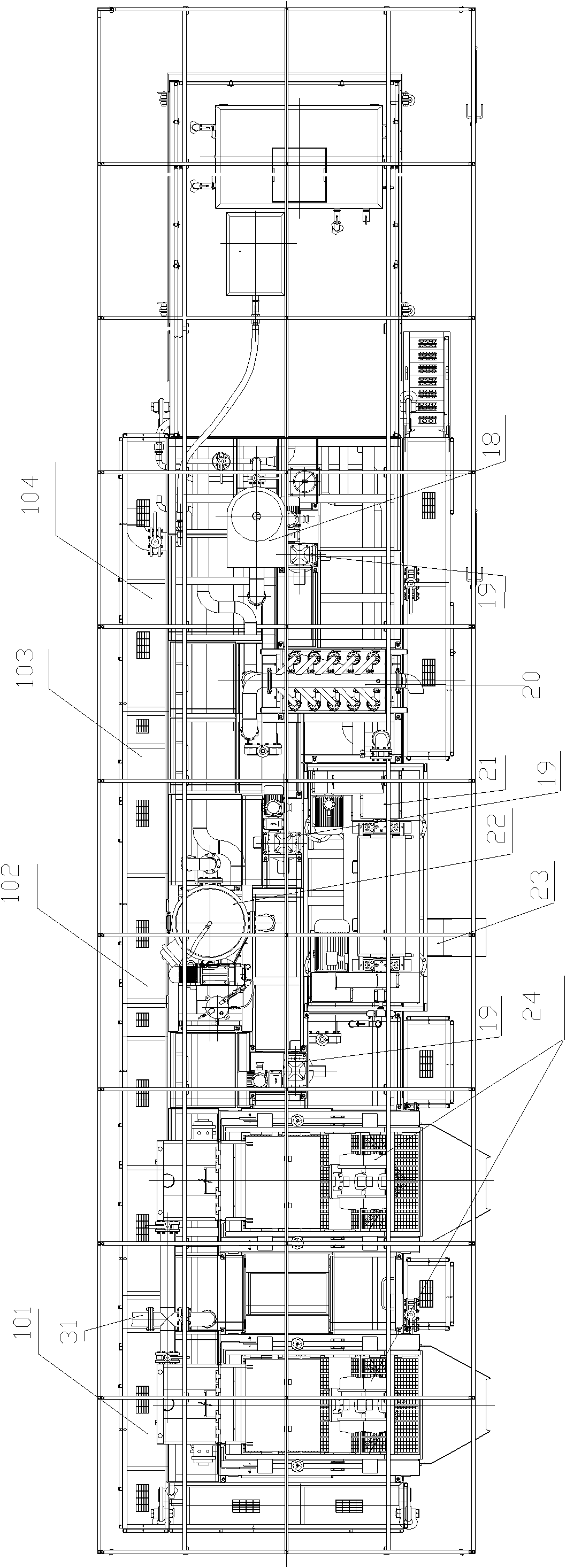

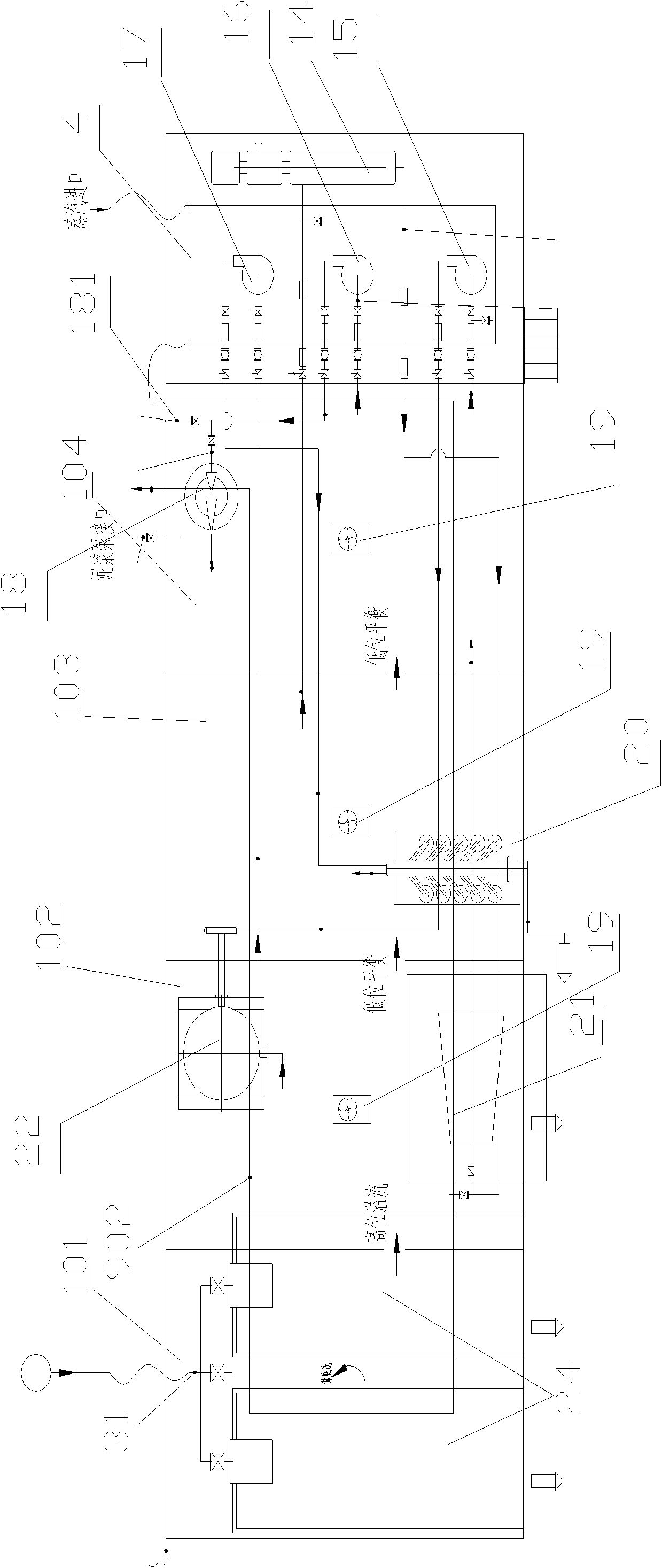

[0038] Such as figure 1 , 2As shown, a low-temperature vehicle-mounted oil drilling and workover drilling fluid purification system includes a mud tank 1, a pump skid 4, solid control equipment, equipment communication pipelines, a cleaning hot water tank, a dosing tank, and a steam heating pipeline. The solid control equipment is installed on the tank surface of the mud tank 1. The mud tank 1 is equipped with a sand cleaning port 105, and is divided into a grit chamber 101, a degassing chamber 102, a centrifuge chamber 103, and a mixing chamber 104. Arranged from left to right, each warehouse has a sequential overflow port, and each warehouse is equipped with a sand cleaning port 105. The solid control equipment includes two vibrating screens 24, a degasser 22, and a desilter device 20, a high-speed centrifuge 21, three agitators 19, a mixing funnel 18, three centr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com