A modified masterbatch suitable for fiber-reinforced PET engineering plastics and its preparation method

A technology for modifying masterbatches and engineering plastics, applied in the field of engineering plastics, can solve the problems of increasing the synergy of additives in the weighing process, limiting the application of PET engineering plastics, and poor surface quality of injection molded parts, and simplifying the material weighing process. , The effect of large filling amount and easy extrusion and granulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

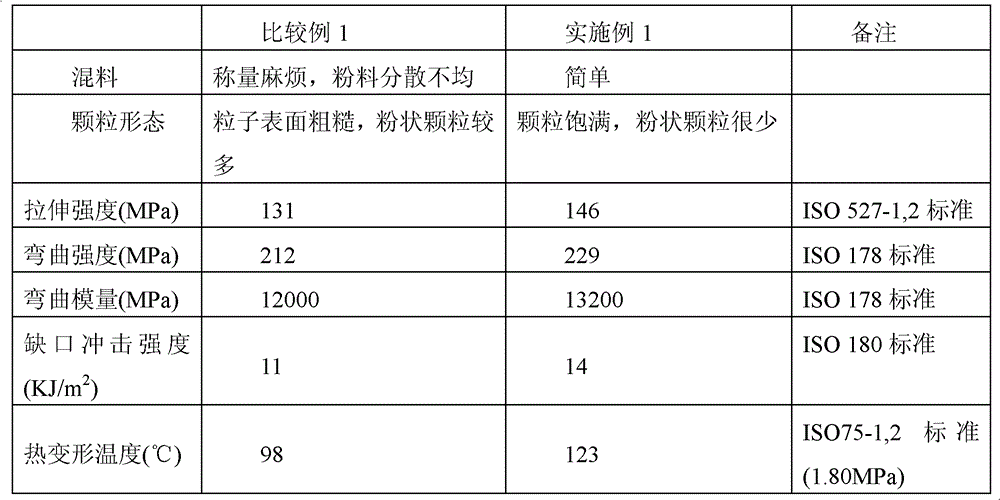

Embodiment 1

[0040] 100 parts of extrusion grade PETG (Eastman grade is GN120), 3 parts of lubricant PETS, 30 parts of nucleating agent ADD-PET301, 40 parts of toughening agent AX8900, 4 parts of antioxidant P262, 5 parts of light stabilizer Agent UV-531, 10 parts of colorant channel black, mixed in a high-speed mixer for 5 to 10 minutes, melted, blended, extruded and granulated through a co-rotating parallel twin-screw extruder to obtain modified masterbatches. The twin-screw extruder is a twin-screw extruder, the temperature range of the extruder barrel is 145-230°C, the screw speed is controlled at 150-800 rpm, and the extruder speed is 500 rpm , the temperature is set to 135°C, 150°C, 165°C, 175°C, 180°C, 180°C, and the die head temperature is 175°C.

[0041] In practical application, the optimal ratio of PET resin to the modified masterbatch is 10:1. By using the modified masterbatch, PET engineering plastics can be endowed with good comprehensive properties. Formula: PET (CZ 328): ...

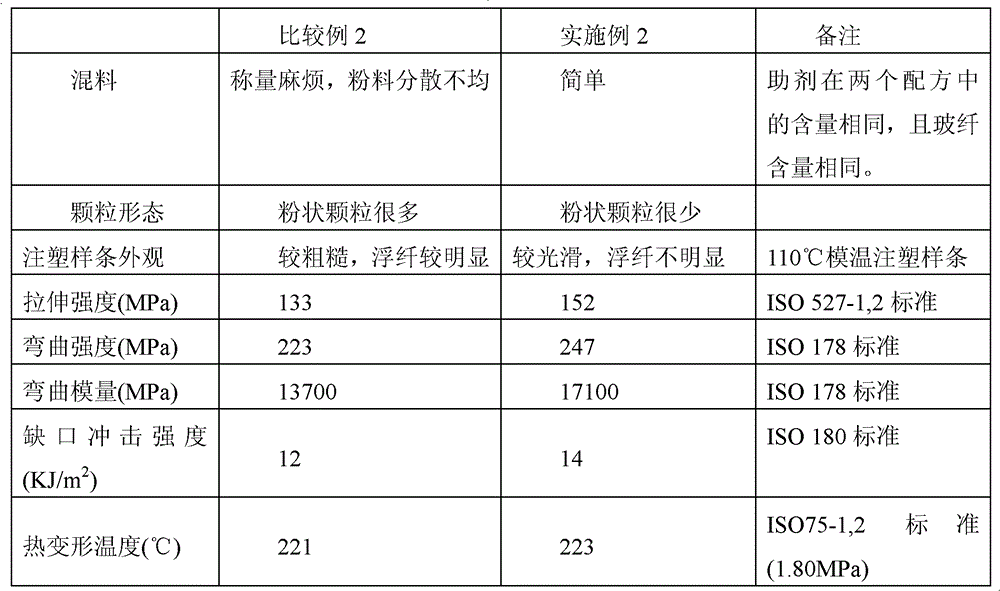

Embodiment 2

[0057] 100 parts of extrusion-grade PETG (Eastman grade EB062), 5 parts of lubricant EBS and 4 parts of silicone lubricant, 25 parts of nucleating agent MB-HDN, 2 parts of antioxidant 1010 and 4 parts of antioxidant Agent 168, 10 parts of light stabilizer UV-531, mixed by a high-speed mixer for 5 to 10 minutes, and granulated in a twin-screw extruder parallel to the same direction, the extruder speed is 400 rpm, and the temperature is set at 140 ° C , 155°C, 170°C, 190°C, 200°C, 200°C, die head temperature 195°C.

[0058] In actual application, the dosage ratio of PET resin and modified masterbatch is 10:1. Using the masterbatch, PET engineering plastics can be endowed with high modulus, high strength, good surface quality, high heat distortion temperature and good weather resistance.

[0059] PET (the trade mark is CZ 328): 100 parts; the modified masterbatch of embodiment 2: 10 parts; glass fiber (988A, boulder glass fiber): 50wt%.

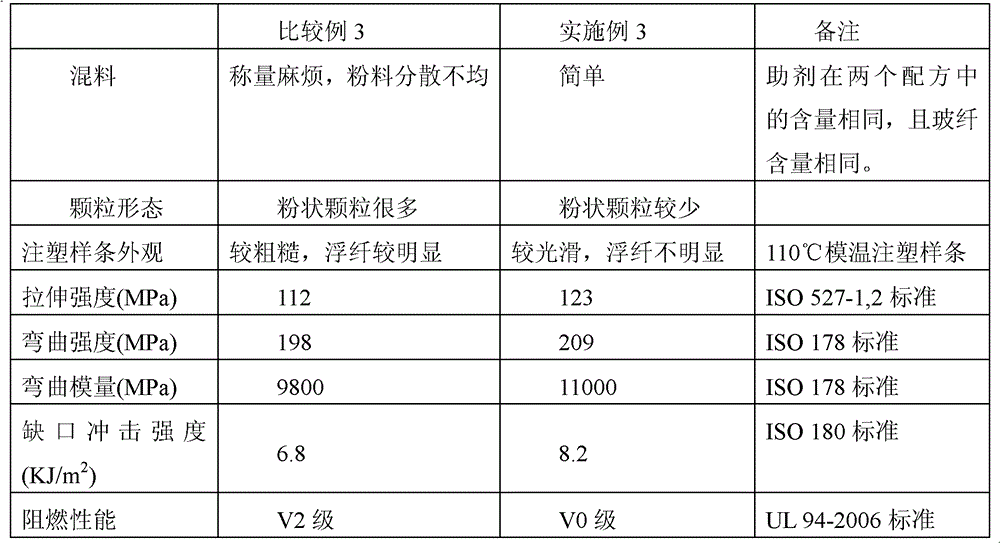

Embodiment 3

[0074] With 100 parts of extrusion-grade PETG (Eastman brand is EB062), 4 parts of lubricant EBS and 6 parts of silicone, 10 parts of nucleating agent NAV101, 3 parts of antioxidant 1010 and 6 parts of antioxidant 168, and 120 parts of flame retardant red phosphorus and 15 parts of channel carbon black were mixed in a high-speed mixer for 5 to 10 minutes, and granulated in a twin-screw extruder with a speed of 400 rpm and a temperature of 140°C and 155 °C, 170 °C, 190 °C, 200 °C, 200 °C, the die head temperature is 195 °C.

[0075] In practical applications, the ratio of PET resin to modified masterbatch is 10:1, which is suitable for flame-retardant PET engineering plastic formulations. Using the masterbatch, PET engineering plastics can be endowed with high modulus, high strength, good surface quality, and better flame retardant effect.

[0076] PET (the trade mark is CZ 328): 100 parts; the modified masterbatch of embodiment 3: 10 parts; glass fiber (988A, boulder glass fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com