Water purifier

A pure water machine and main engine technology, applied in the field of water treatment, can solve the problems that the operating status of the filter element cannot be directly displayed, the operating status of the machine cannot be grasped in a timely manner, and it is unfavorable for the use and maintenance of the machine, so as to overcome rust, paint peeling, The effect of saving installation process, saving material cost and production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

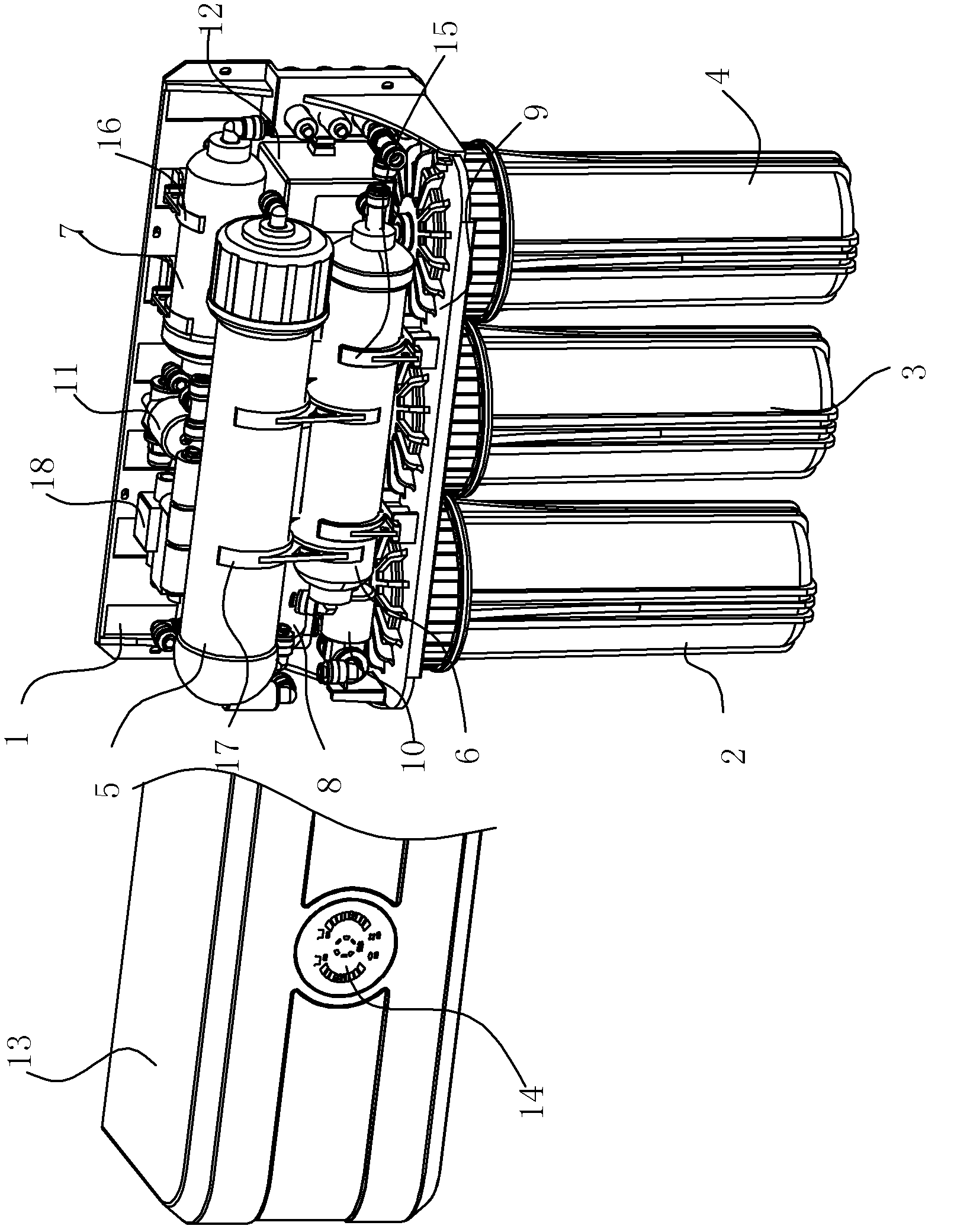

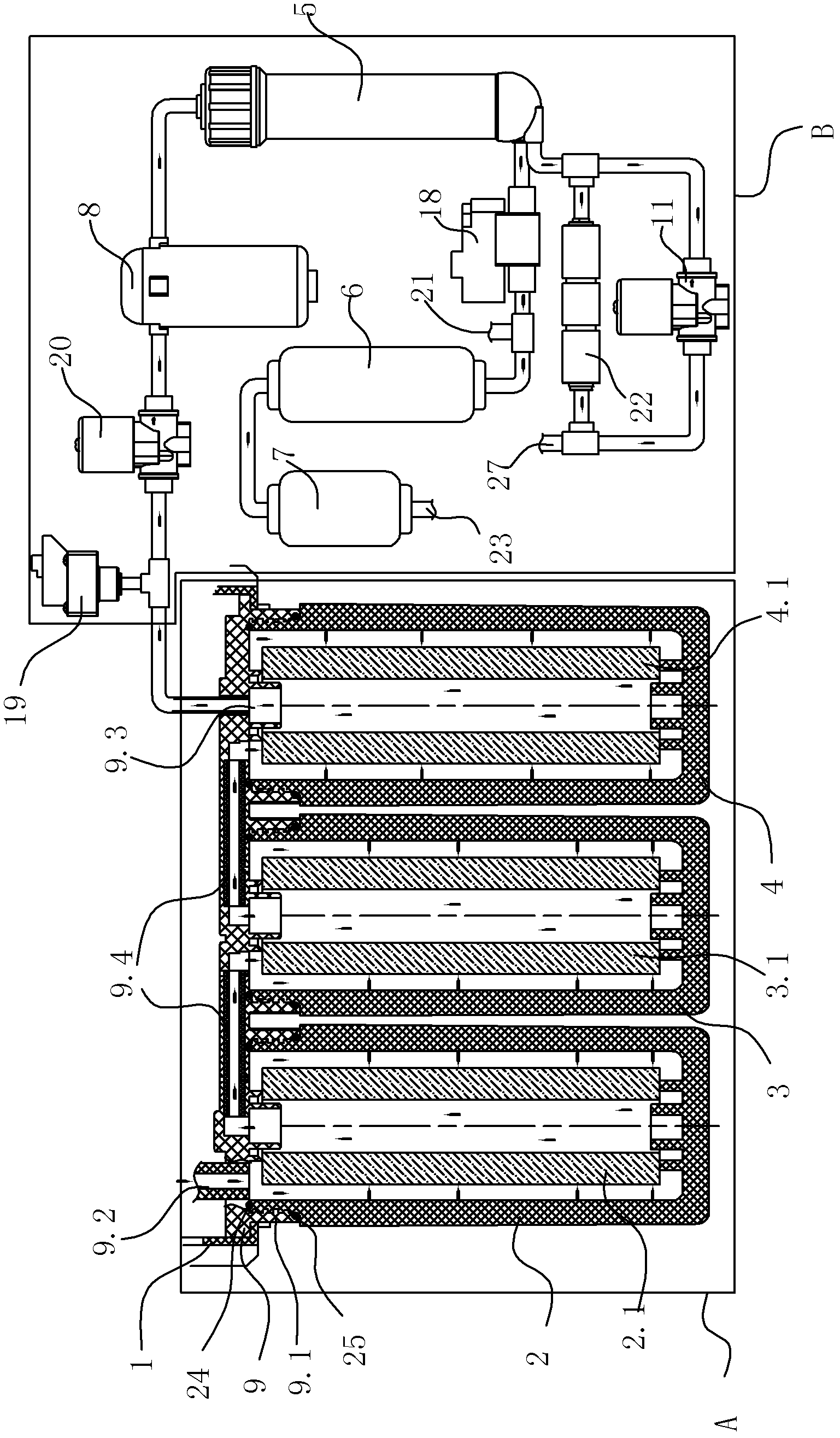

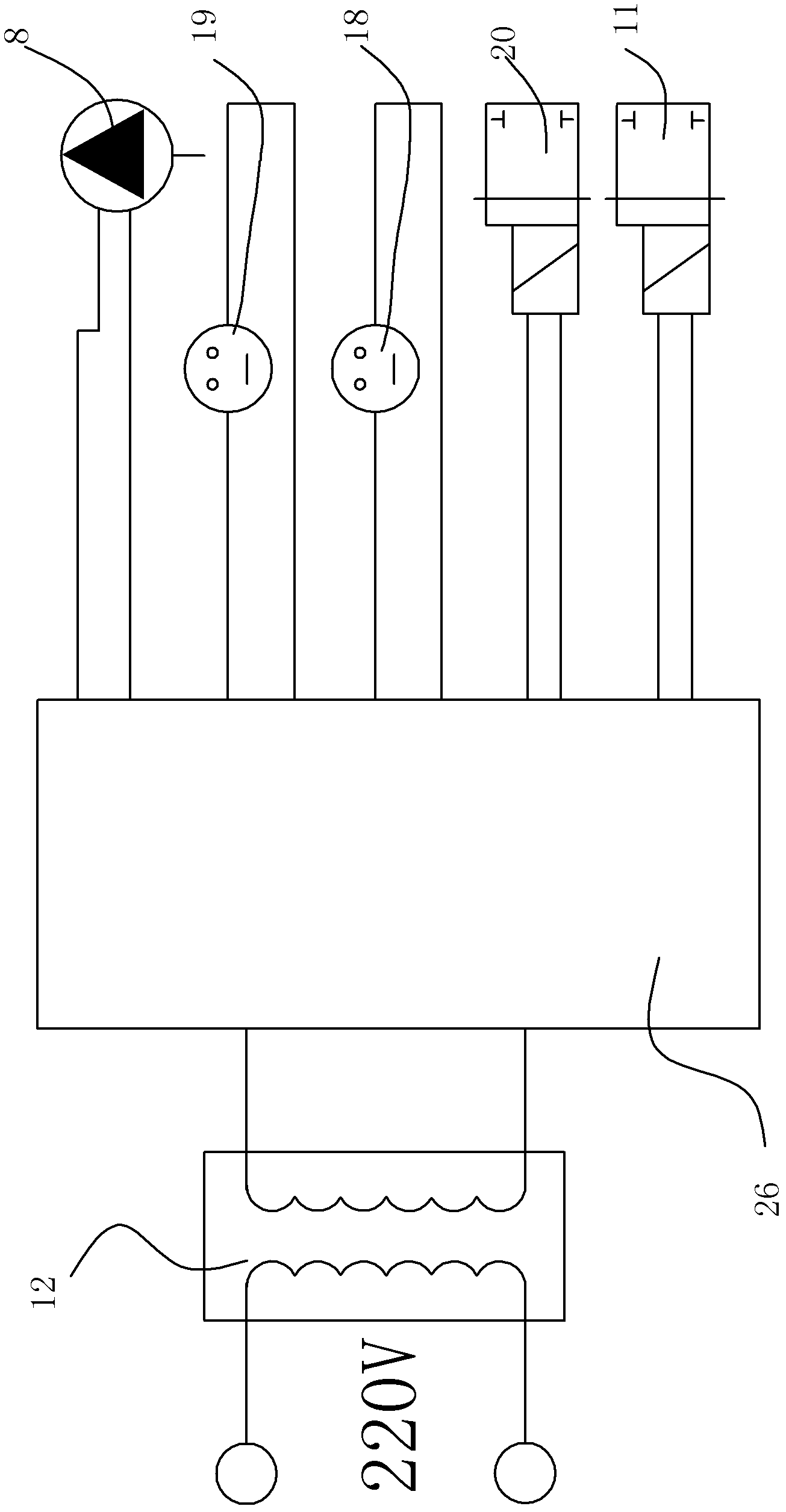

[0022] Such as Figure 1-4 As shown, a new one-piece pure water machine includes a host hanger 1, a machine cover 13, a fully automatic control system, and a coarse filter system A and a fine filter B installed on the host hanger 1. The plate 1 and the machine cover 13 are made of plastic, and there are two hanging holes on the rear end surface of the host hanging plate 1, so that the host can be hung up during use to save space; the coarse filtration system A includes three filter bottles 2 and 3 and 4, each filter bottle 2, 3 and 4 is provided with a water inlet hole and a water outlet hole, wherein the filter bottle 2 is provided with a PP filter element 2.1, the filter bottle 3 is provided with a UDF filter element 3.1, and the filter bottle 4 is provided with a There is a CTO filter element 4.1, the filter bottle 3 is set between the filter bottle 2 and the filter bottle 4, and a one-piece cover corresponding to the bottle mouths of the filter bottles 2, 3 and 4 is provid...

Embodiment 2

[0028] When the source water pressure is less than 0.5KG or there is no source water pressure, the booster pump 8 is used as a self-priming pump, the low pressure switch 19 is used as a water flow switch, and the rest remain unchanged. When the water flow switch detects that there is water, the system Automatically start working, when there is no water, the system stops working.

[0029] The invention is composed of all plastic parts, which overcomes the defects that the existing pure water machine hanging boards adopt metal parts and are easy to rust and paint off.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com