Height adjusting plate

A height-adjusting board and board-lapping technology, which is applied in the directions of transportation, packaging, loading/unloading, etc., can solve inconvenience and other problems, achieve the effect of avoiding manual pulling and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described below in conjunction with the accompanying drawings and specific embodiments.

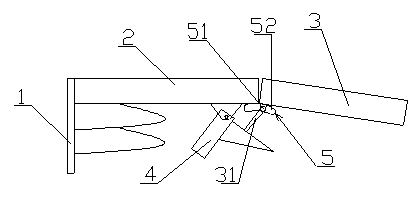

[0010] The height adjustment plate includes a frame 1, a main panel 2, a board 3, a support foot 4 and a connecting mechanism 5, one side of the main panel 2 is hinged with the frame 1, and the other side is connected to the board through the connecting mechanism 5. 3 are hinged on one side, and the support foot 4 is hinged on the lower side of the main panel 2 on the side where the main panel 2 and the strap 3 are connected. , when the strap is rotated to the horizontal position, the flexible plate will rotate with the strap to push the supporting feet to the horizontal position.

[0011] The connecting mechanism 5 includes a rotating shaft 51 and an arc block 52. The arc block 52 is welded to the corresponding side of the main panel. In the hole, the bottom surface of the strap is in contact with the upper side of the arc block. The upper side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com