A welding repair method

A welding repair and full welding technology, applied in the field of welding repair, can solve the problems of mechanical equipment damage, unsafe, vicious accidents, etc., and achieve the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

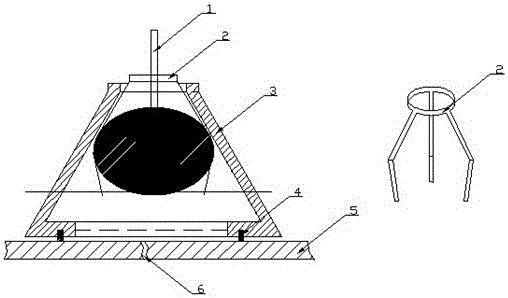

[0021] Referring to accompanying drawing, the present invention has adopted a kind of welding repair method,

[0022] Specific welding repair steps:

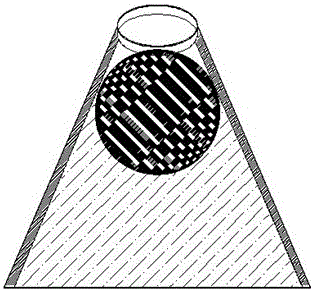

[0023] Step 1: Place the jacket together with the card and the steel ball with handle in the jacket in the forming cover in advance. The jacket is a three-arm elastic clamp. The diameter of its circular mouth is slightly larger than the circular upper opening of the forming cover. The three clamping arms of the jacket are stretched from the circular upper opening of the forming cover. The opening is placed in the middle of the three clamping arms of the jacket to form a suspended clamping state.

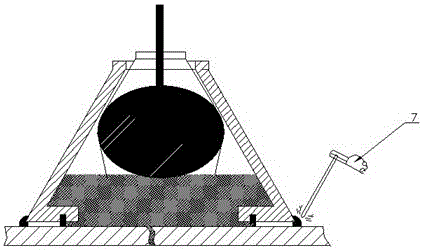

[0024] Step 2: Insert asbestos ring strips (the purpose of using asbestos component strips is to prevent high temperature damage during subsequent welding) evenly in the bottom square groove of the forming cover. Try to focus on the leakage of the container wall, and use a little force (the asbestos strip and the container wall to ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com