A full counterflow mass flow unit and a tray equipped with the unit

A countercurrent, tray technology, applied in the field of chemical engineering, can solve the problems of low utilization rate of the column section and the pressure drop of the tray, and achieve the effect of increasing the effective mass transfer area, widening the gas phase load range, and improving the utilization rate of the tray.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

[0023] In the φ650 experimental column, the experiment is carried out by using the full counterflow mass flow tray provided by the present invention. The parameters of the tray structure are as follows:

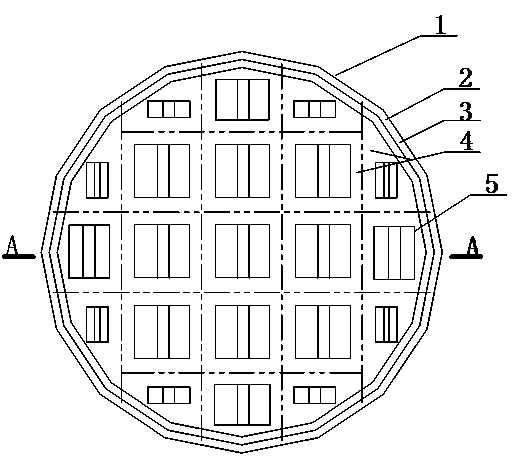

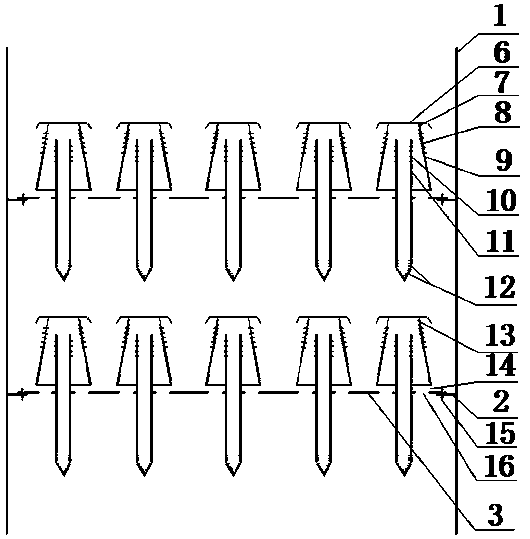

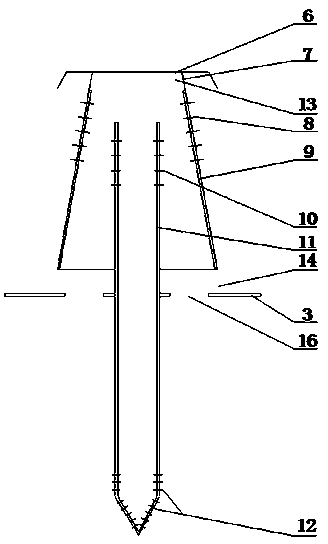

[0024] There is no downcomer, and there are 4 mass transfer unit areas. The mass transfer unit in each mass transfer unit area is 158mm×158mm in size, the plate spacing is 450mm, and the weir height is 50mm. figure 1 As shown, the schematic diagram of the cross-sectional structure of the tray is shown in figure 2 As shown, the schematic diagram of the cross-sectional structure of the mass transfer unit is shown in image 3 shown.

Embodiment 1-2

[0026] Compared with Example 1, the end plate is extended to the gas-liquid separation liquid distribution plate, the injection channel is closed, and the opening ratio of the injection hole of the side plate is correspondingly increased, so that the cross-sectional area of the injection hole of the side plate accounts for the outer surface area of the mass transfer unit The ratio of is the same as the ratio of the sum of the cross-sectional areas of the side plate injection holes and injection channels to the external surface area of the mass transfer unit in Example 1-1. Other structures are the same as in Example 1-1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com