False eyelash and production method thereof

A manufacturing method and technology of false eyelashes, which are applied in the direction of baldness-covering wigs, cap products, textiles, and papermaking, can solve the problems of base fracture and structural damage of false eyelashes, and achieve the effect of preventing breakage and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Regarding the techniques, means and effects used in the present invention, two preferred embodiments are described in detail below with accompanying drawings, which are for illustration purposes only, and are not limited by such structures in patent applications.

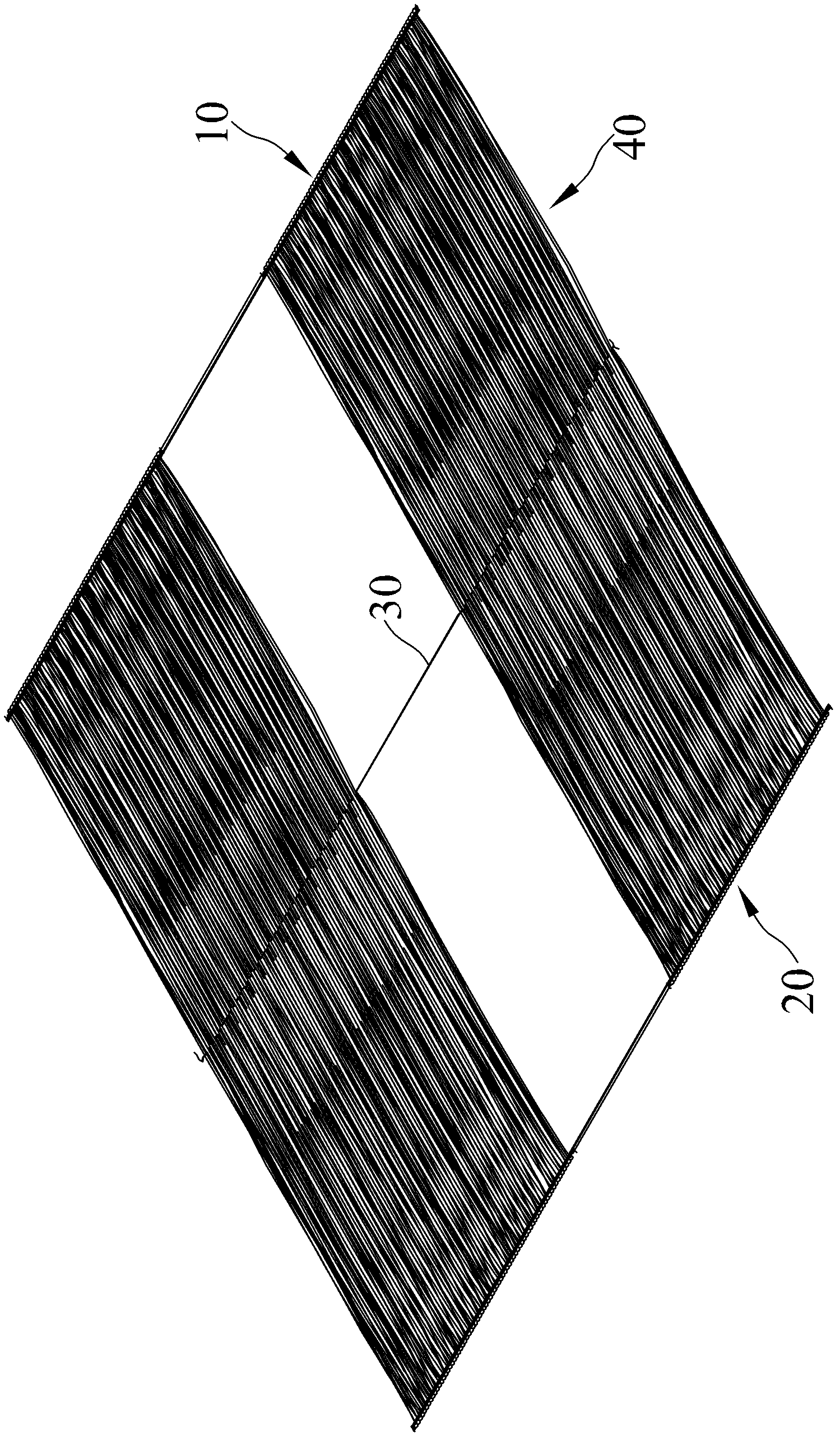

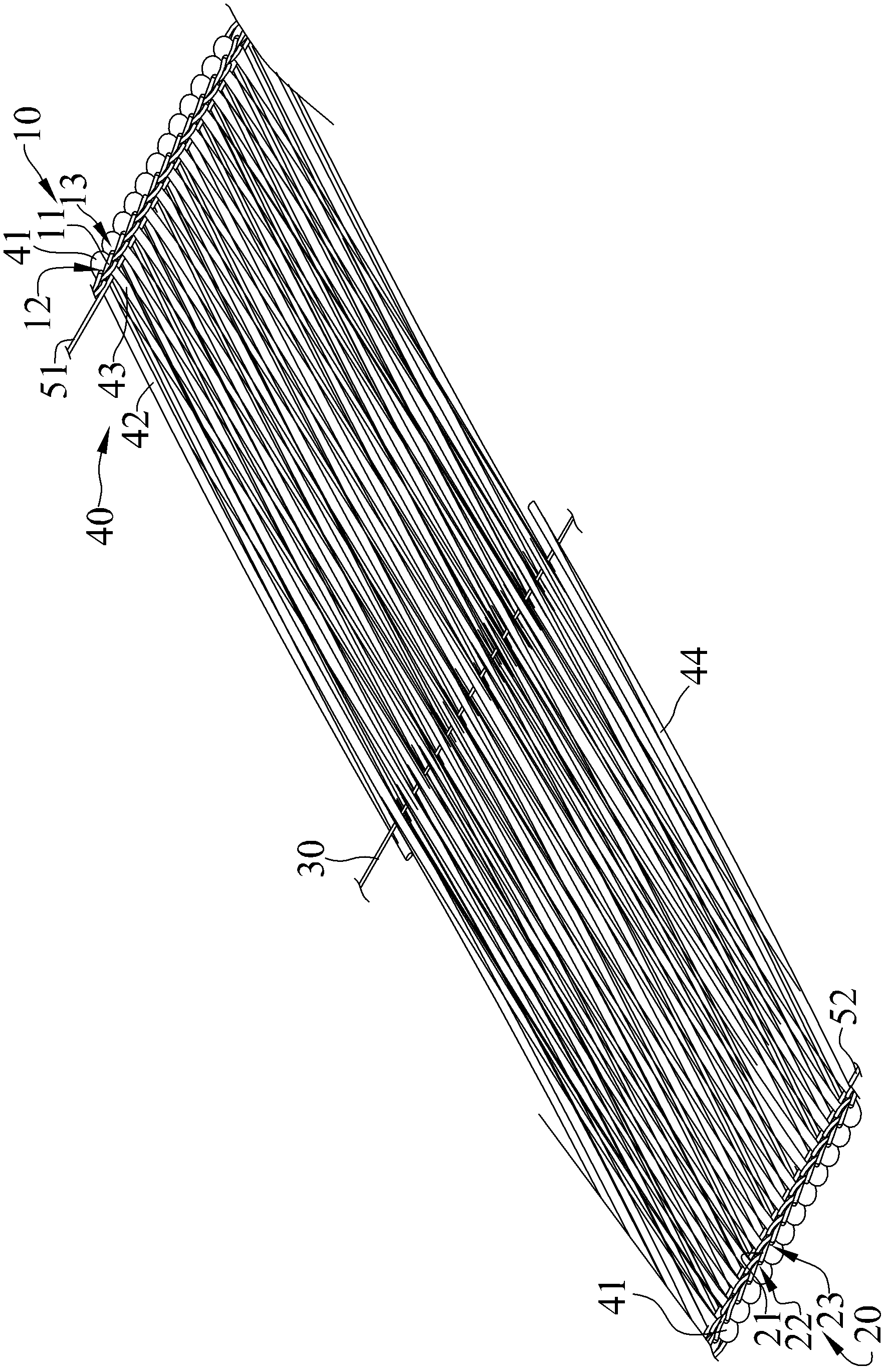

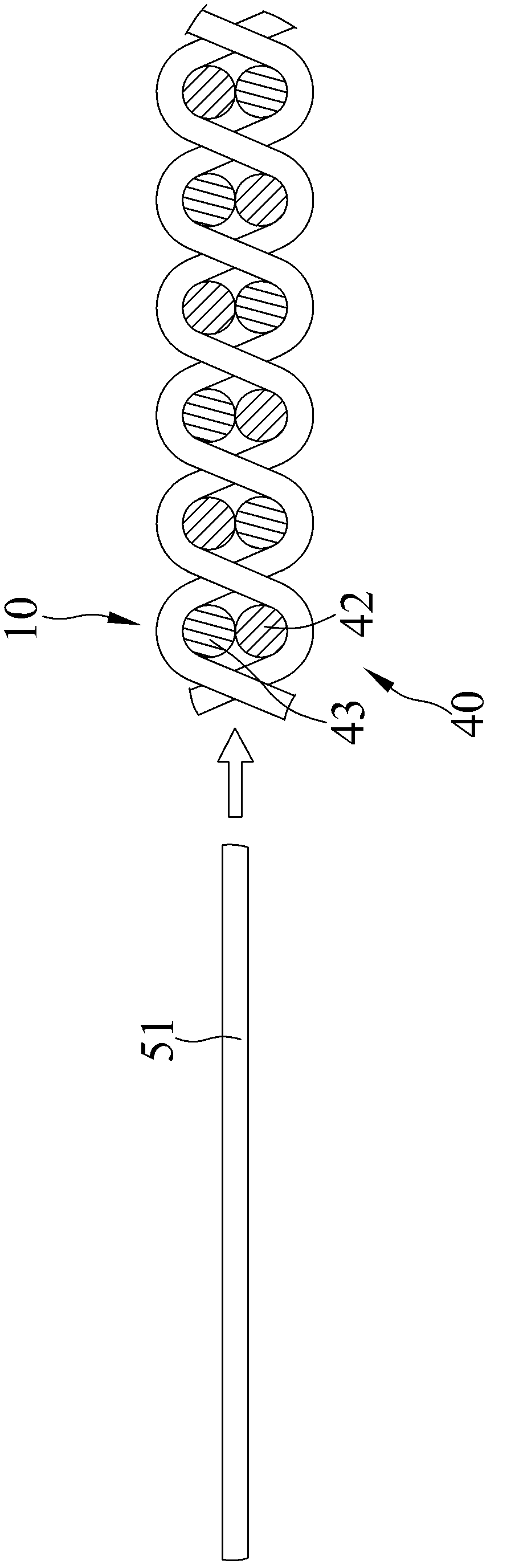

[0034] refer to Figure 1 to Figure 7 , is a three-dimensional appearance view and a cross-sectional view of the false eyelashes according to the first embodiment of the present invention. The manufacturing method of the false eyelashes according to the first embodiment of the present invention is as follows: material preparation → weaving → threading of the first reinforcement thread and the second reinforcement thread → mold cutting → finished product.

[0035] Material preparation: a first base line 10 , a second base line 20 , a reinforcement line 30 , a bundle of eyelash lines 40 , a first reinforcement line 51 and a second reinforcement line 52 are prepared.

[0036] Weaving: the first basic thread 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com