Piston unit

A technology of piston and radial piston engine, applied in the direction of piston, tubular piston, reciprocating piston engine, etc., to maximize the unloading force and improve the starting efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

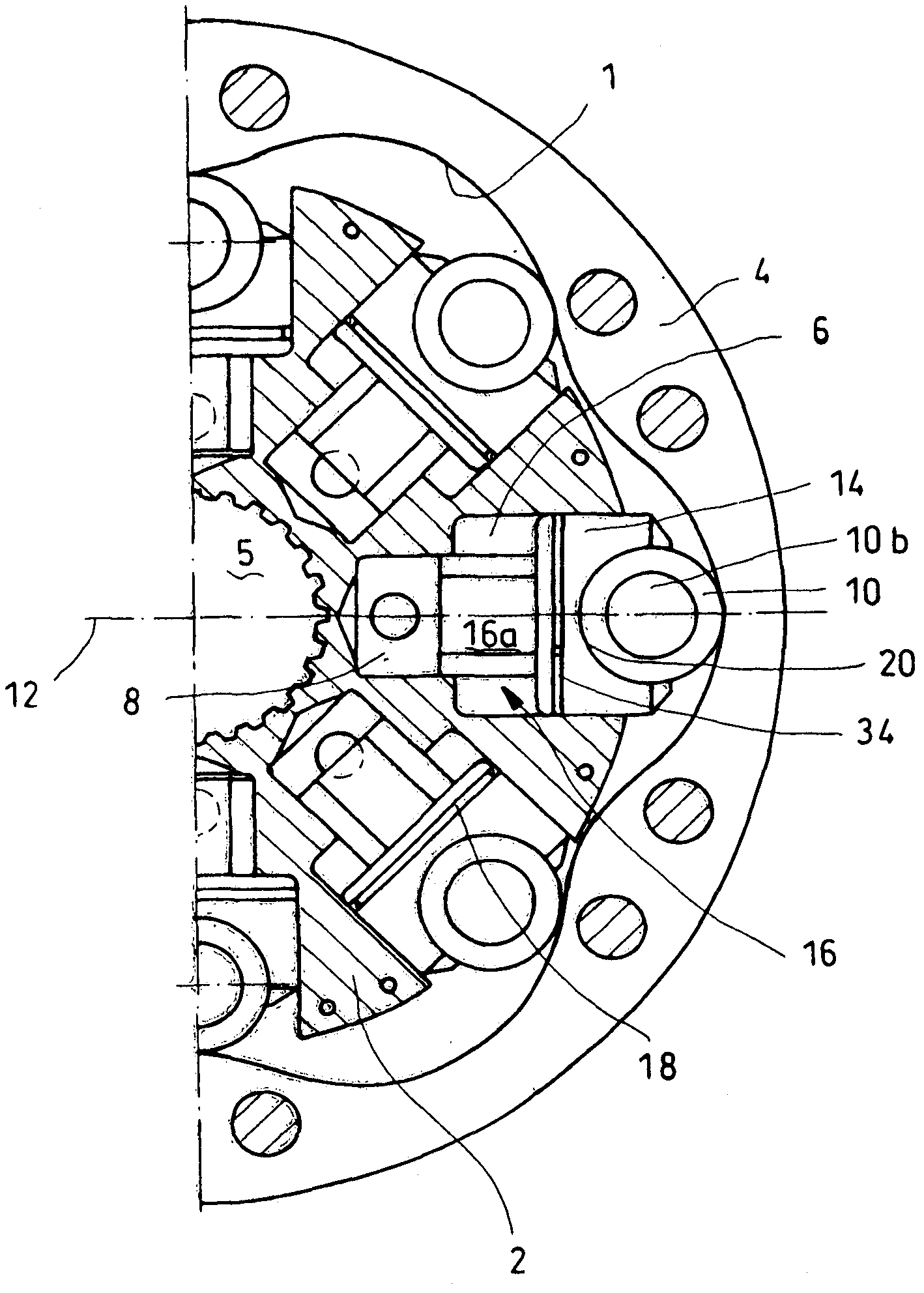

[0026] figure 1 A cutaway side view of a radial piston machine with a first exemplary embodiment of a piston unit 14 , 16 , 10 according to the invention is shown. The radial piston machine has an annular, undulating stroke cam 1 and eight cylinders 6, 8 with corresponding piston units 14, 16, 10, wherein in figure 1 Only three cylinders are shown in full and the other two cylinders are partially shown in . The cylinders 6 , 8 are arranged radially or star-shaped in the rotor 2 , while the travel cam 1 is formed on a disc cam 4 . The rotor 2 and the disc cam 4 are rotatable relative to each other. A radial piston machine of the type shown is usually used as a hydraulic motor, wherein the rotor can be fixed via a shaft 5 or a travel cam to the element to be driven.

[0027] Each cylinder 6 , 8 has a main section 6 and, on its side facing the shaft 5 , a radially stepped guide section 8 .

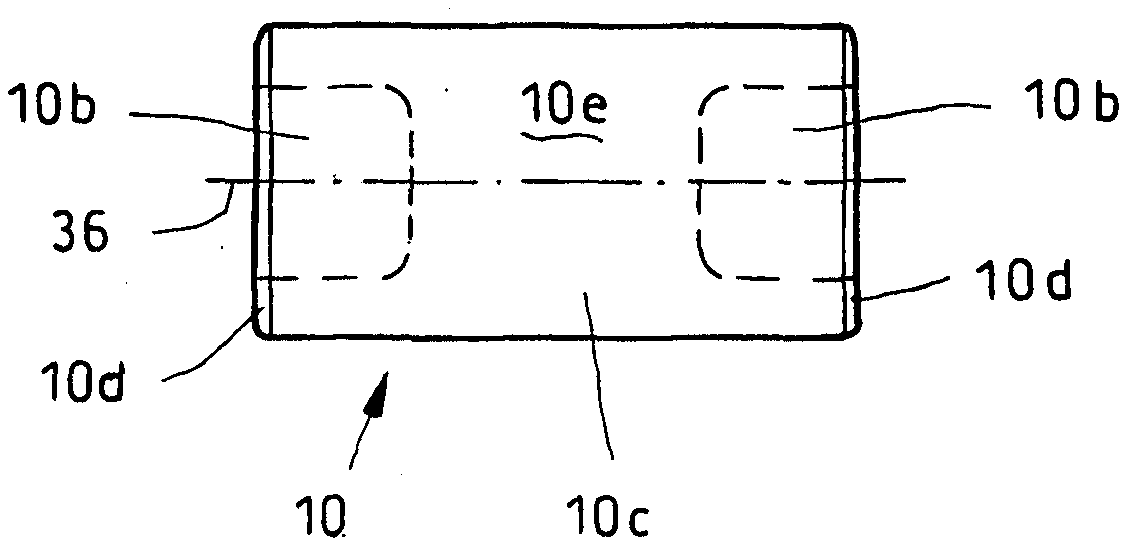

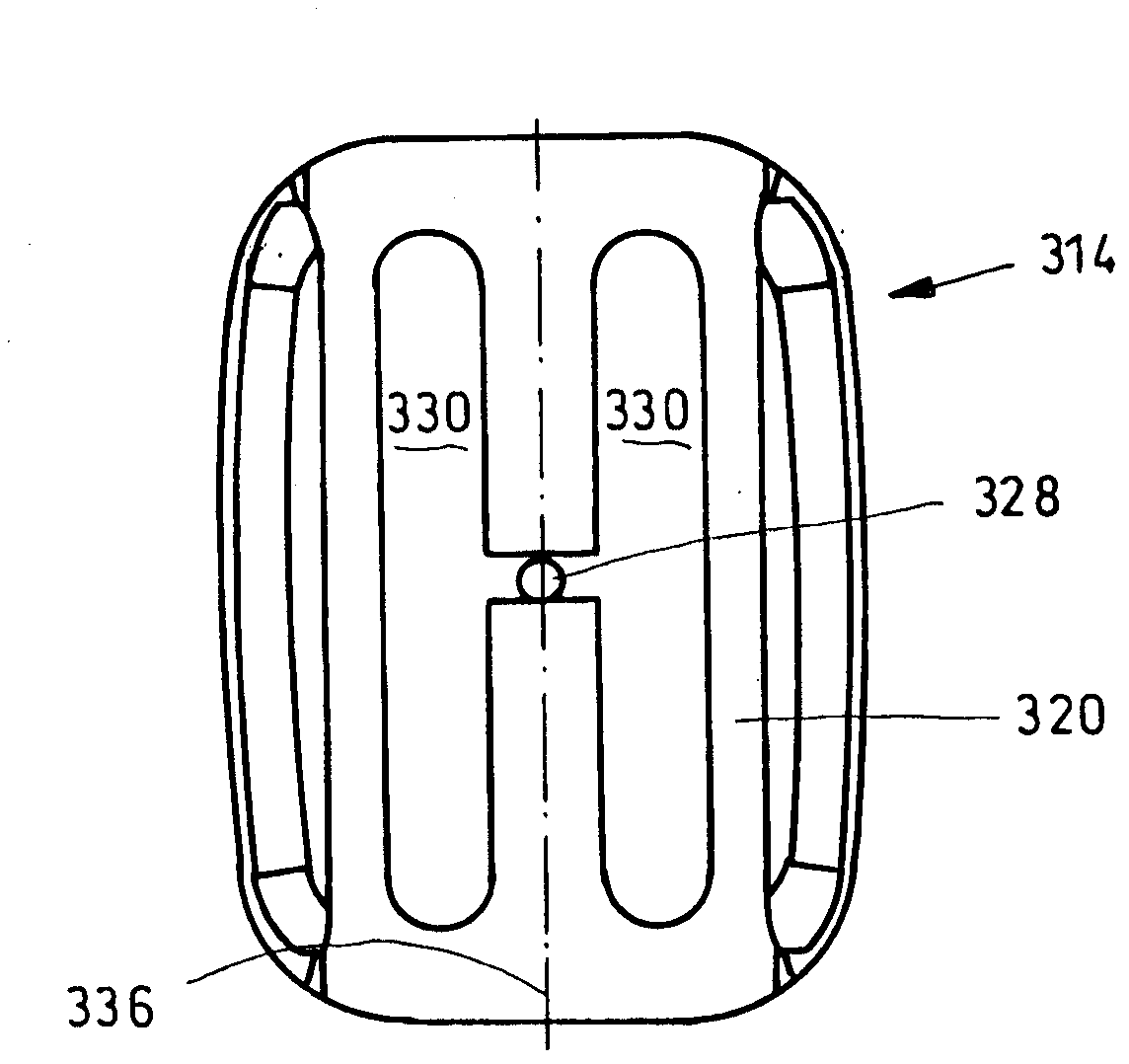

[0028] Each piston unit 14 , 16 , 10 has a roller 10 which, when the rotor 2 rotates,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com