Multifunctional support trolley for tunnel arches

A multi-functional, trolley technology, applied in tunnels, tunnel linings, shaft linings, etc., can solve problems such as hidden safety hazards, low efficiency, and high labor intensity, saving construction time, improving work efficiency, and saving labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

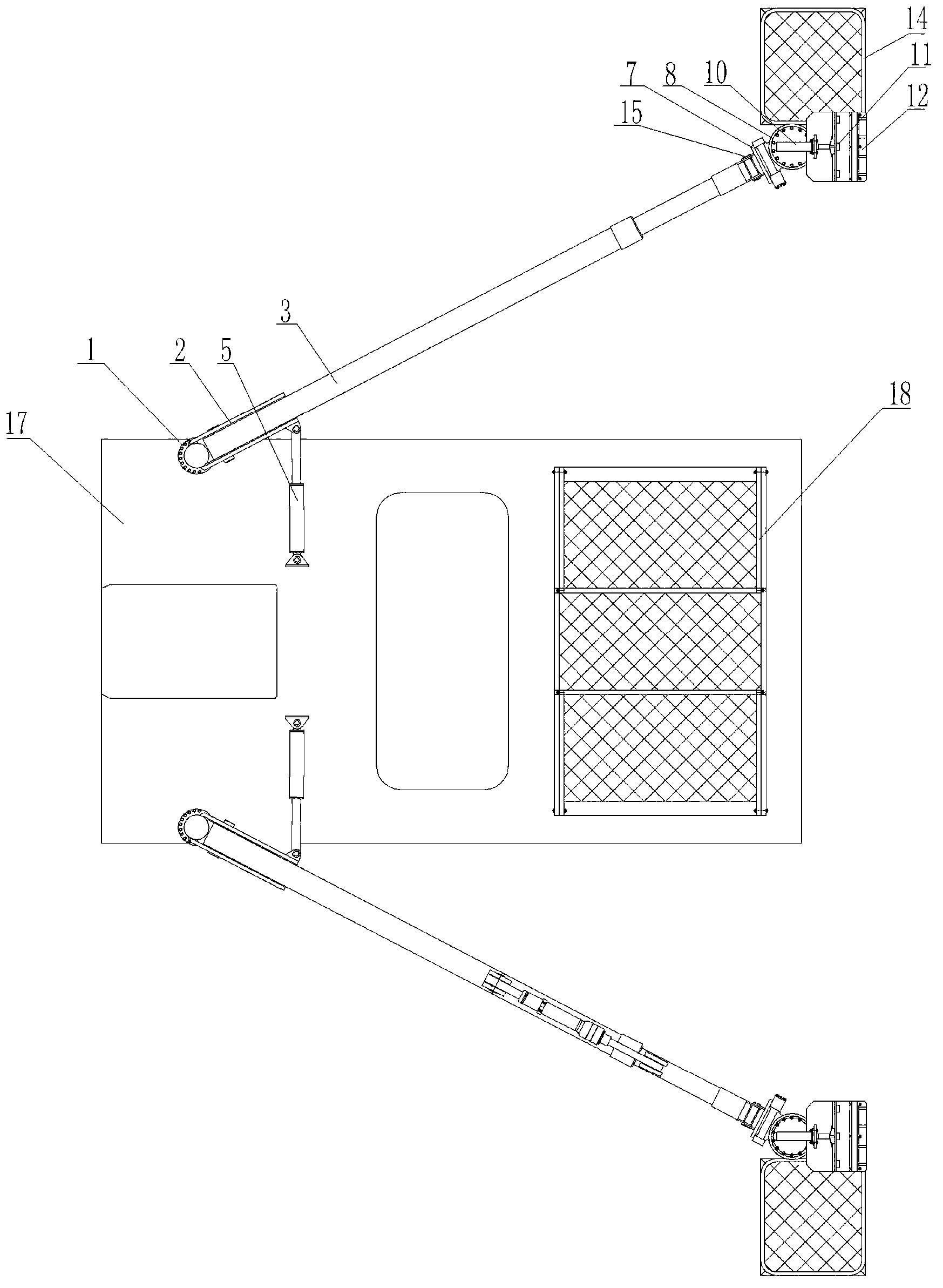

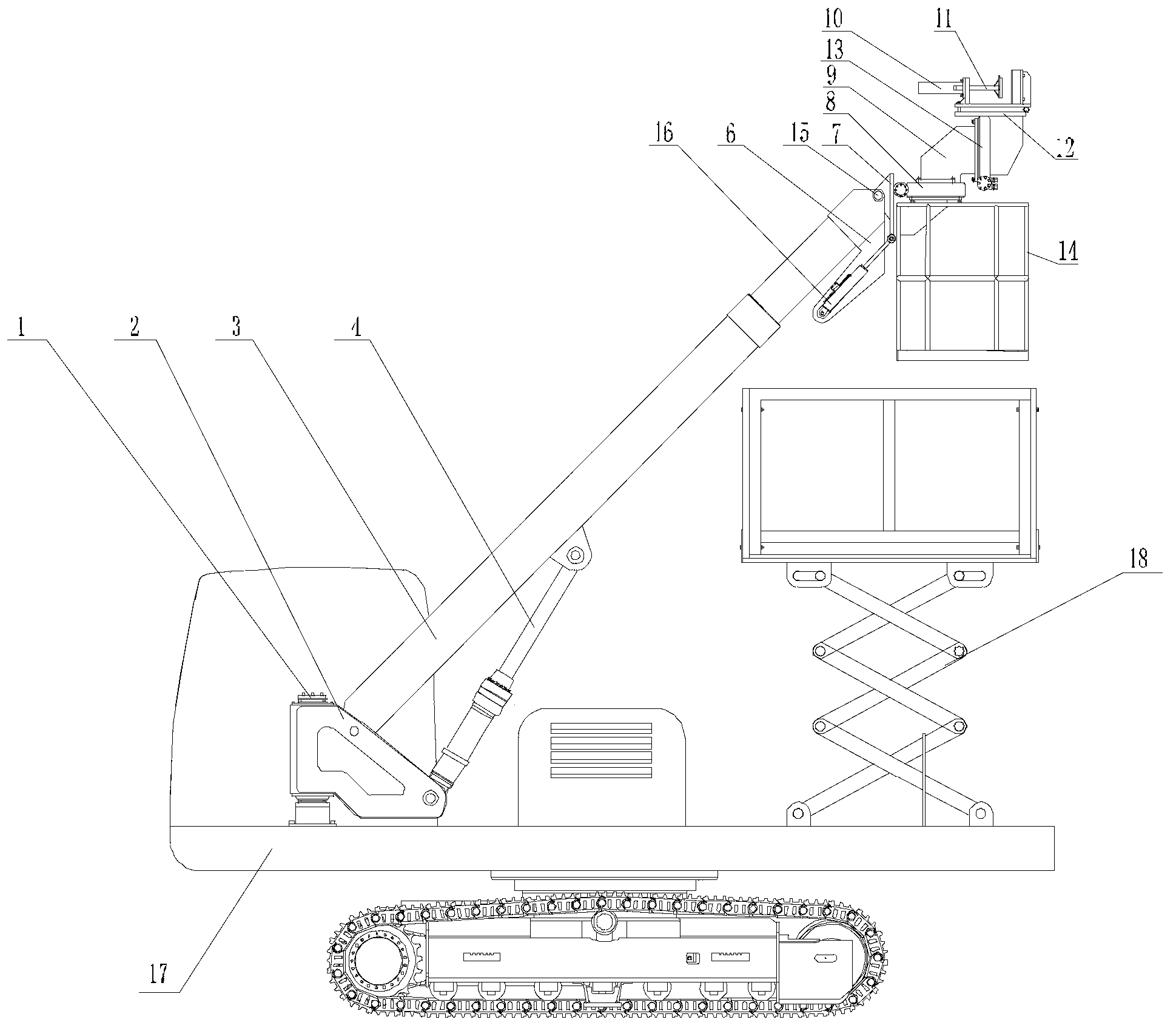

[0010] Such as figure 1 , figure 2 As shown, a tunnel arch multifunctional support trolley is equipped with a scissor fork lift platform 18 on the trolley platform 17, and is characterized in that: a special all-round manipulator for the tunnel is installed on both sides of the trolley platform 17, and the Tunnel-specific all-round manipulator includes telescopic arm 3, one end of telescopic arm 3 is installed on the telescopic arm rotating bracket 2, the rotating seat 1 is housed on the telescopic arm rotating bracket 2, and the telescopic arm rotating oil cylinder 5 is housed on the telescopic arm rotating bracket 2; One end of the oil cylinder 4 is installed on the telescopic arm rotating bracket 2, and the other end is installed on the telescopic arm 3. A manipulator is installed on the front end of the telescopic arm 3. The manipulator includes a leveling oil cylinder mount 6 mounted on the front end of the telescopic arm 3. The leveling rotating base 7 is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com