Integrated wall structure

A technology for wall structure and insulation layer, applied in the direction of walls, building components, building structures, etc., can solve the problem that it is difficult to meet the safety and fire protection requirements of building walls, the cost of composite energy-saving insulation walls is high, and the wall is wrapped in reinforced concrete. External and other issues, to achieve good thermal insulation effect, improve construction quality, increase the effect of construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

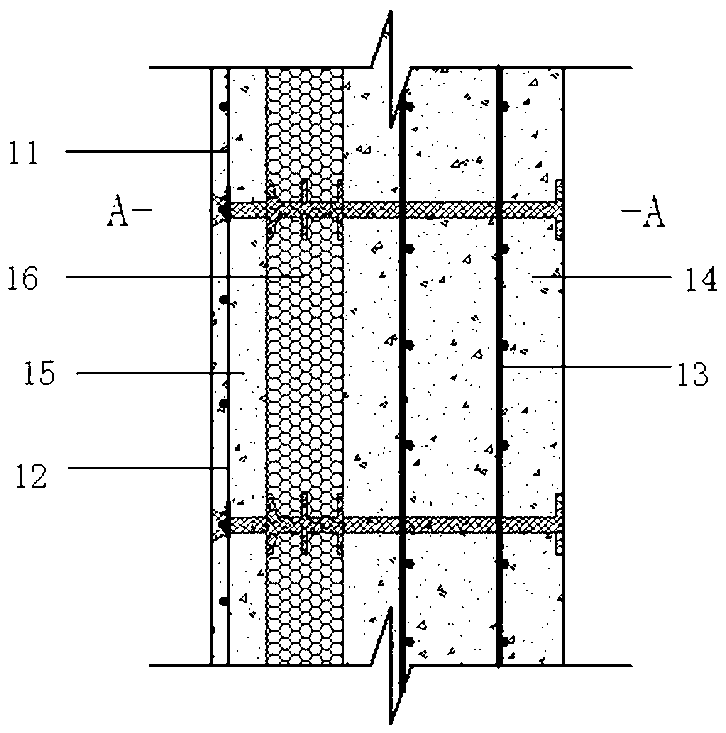

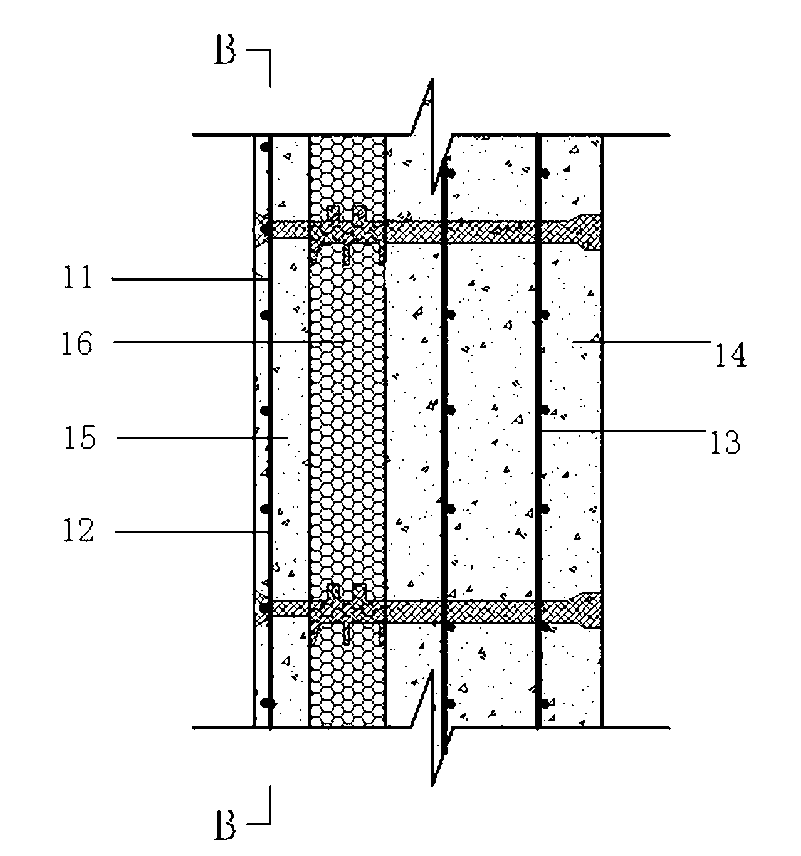

[0022] The present invention will be described in more detail below with examples in conjunction with the accompanying drawings.

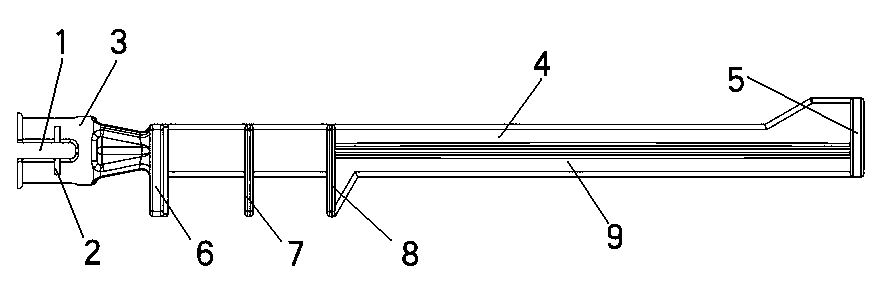

[0023] combine Figure 4-Figure 6 . The composition of the connector used in the present invention includes a connecting plate 4, a plug that matches the slot on the EPS module is provided at one end of the connecting plate, and an end plate 5 matching with a detachable template is provided at the other end of the connecting plate , The outer side of the plug is connected with a columnar terminal 3, and a "+" shaped steel bar installation groove 1 is opened on the columnar terminal. The side of the columnar end is provided with a reinforcing bar positioning groove 2 . The plug is made up of an inner board 8, an outer board 6 and a socket board 7 positioned between the inner and outer boards. The columnar end 3 is connected to the outside of the outer plate 6 . Rib plates 9 are provided on both sides of the connecting plate. The columnar en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com