Automatic fiber bundle and crimping machine butting device

An automatic docking and fiber tow technology, which is applied in the field of crimping devices, can solve the problems of high labor intensity, inability to guarantee the quality of tow, unsafety, etc., and achieve the effect of ensuring the quality of crimping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

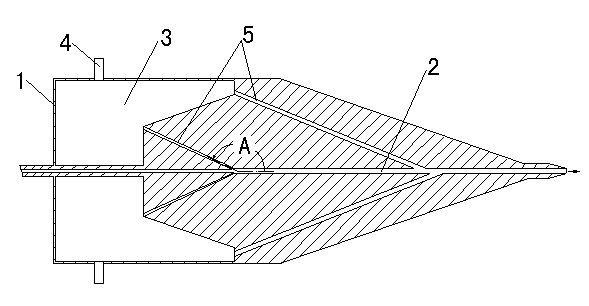

[0013] As shown in the accompanying drawings, the fiber tow automatic access crimping machine device of the present invention mainly includes a main body 1, the middle part of the main body 1 is provided with a wire guide hole 2 passing through the two ends of the main body, and an air storage chamber is provided inside the main body 1 3. The side wall of the main body 1 is provided with an air inlet 2 communicating with the air storage chamber 3, and the front end of the main body 1 is provided with a wire guide air channel 5, one end of the guide wire air channel 5 communicates with the air storage chamber 3, and the other end It communicates with the wire guide hole 2, and the axis of the wire guide air channel 5 is inclined relative to the axis of the wire guide hole 2. The included angle A of ) is greater than 90 degrees, preferably 135 degrees-175 degrees, so that the air intake direction of the wire guide air channel 5 is consistent with the running direction of the tow....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com