High-stability system enzymatic laundry soap composition and production method thereof

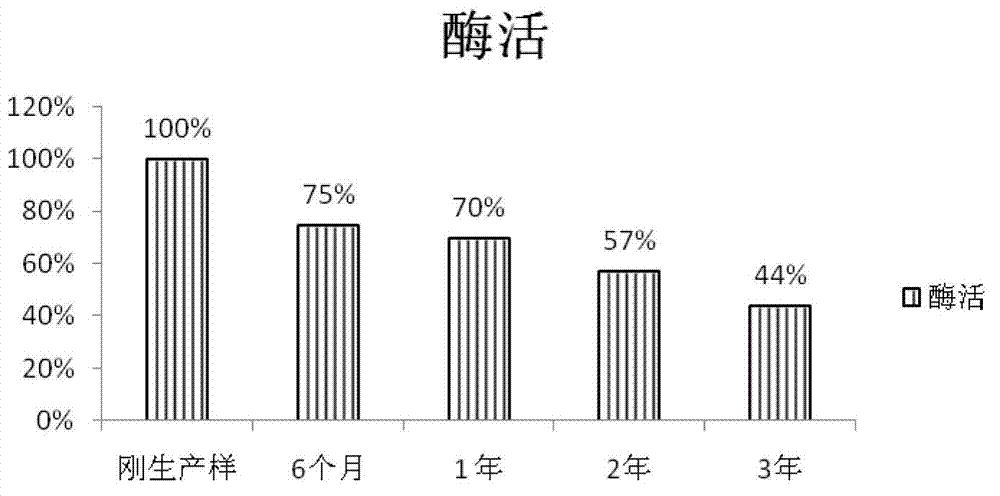

A composition and laundry soap technology, which are applied in the directions of detergent compositions, soap detergent compositions, organic compound-containing detergent compositions, etc., can solve the problems of poor stability of enzyme activity, insufficient preservation rate of enzyme preparations, poor stability, and the like, To achieve the effect of easy laundry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Each group distribution proportion of present embodiment is as shown in table 1:

[0042]Among them, the soap particles are composed of 15% coconut oil sodium soap and 85% tallow sodium soap, the colorant is acid golden yellow-G, the spice is jasmine flavor essence, and the metal ion chelating agent is hydroxyethylene diphosphonic acid ( HEDP), the molding agent is cetearyl ether-50, the enzyme is liquid alkaline protease (Savinase Ultra16XL), the pH regulator is 50% citric acid aqueous solution, and the complex boron-based stabilizer is a combination of 4-FPBA and boric acid. Solvent selects the glycerin of 98% content for use.

[0043] The production process is as follows:

[0044] First prepare the enzyme and its stabilizer solution; put the soap grains into the mixing pot, start the agitator to stir, add the colorant and metal ion chelating agent and stir for 2 minutes, then add cetearyl ether-50, stir for 3 minutes Then add citric acid aqueous solution (20% conce...

Embodiment 2

[0046] Each group distribution proportion of present embodiment is as shown in table 1:

[0047] Among them, the soap particles are composed of 12% palm kernel oil sodium soap and 88% tallow sodium soap, the colorant is Cosmenyl GreenGG (0.01% aqueous solution), the spice is lily flavor essence, and the metal ion chelating agent is hydroxyethylene bismuth Disodium phosphonate (HEDP-2Na), cetearyl ether-25 as the forming agent, lauric acid as the pH regulator, liquid alkaline protease (Savinase Ultra16XL) as the enzyme, and 4-acetophenone as the complex boron-based stabilizer A combination of boric acid and borax, and 99% ethylene glycol as the solvent.

[0048] The production process is as follows:

[0049] First prepare the enzyme and its protective agent solution; put the soap grains into the mixing pot, start the agitator to stir, add lauric acid, colorant and metal ion chelating agent and stir for 2 minutes, then add cetearyl ether-25, After stirring for 2 minutes, add t...

Embodiment 3

[0051] Each group distribution proportion of present embodiment is as shown in table 1:

[0052] Among them, the soap particles are made of whole vegetable oil soap particles: 10% palm kernel oil sodium soap, 90% palm oil sodium soap, the colorant is paint color paste 8401, the fragrance is rose flavor essence, and the metal ion chelating agent is ethylenediamine Tetrasodium tetraacetate (EDTA-4Na), polyvinylpyrrolidone PVP is used as the molding agent, lactic acid is used as the pH regulator, cellulase is used as the enzyme, acetamidophenylboronic acid and boric acid are used as the complex boron-based stabilizer, and the solvent is selected 99.5% content of propylene glycol.

[0053] The production process is as follows:

[0054] First prepare the enzyme and its protective agent solution; put the soap grains into the mixing pot, start the agitator to stir, add colorant, whitening agent and metal ion chelating agent and stir for 2 minutes, then add polyvinylpyrrolidone PVP, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com