Method for comprehensively extracting effective ingredients in tea

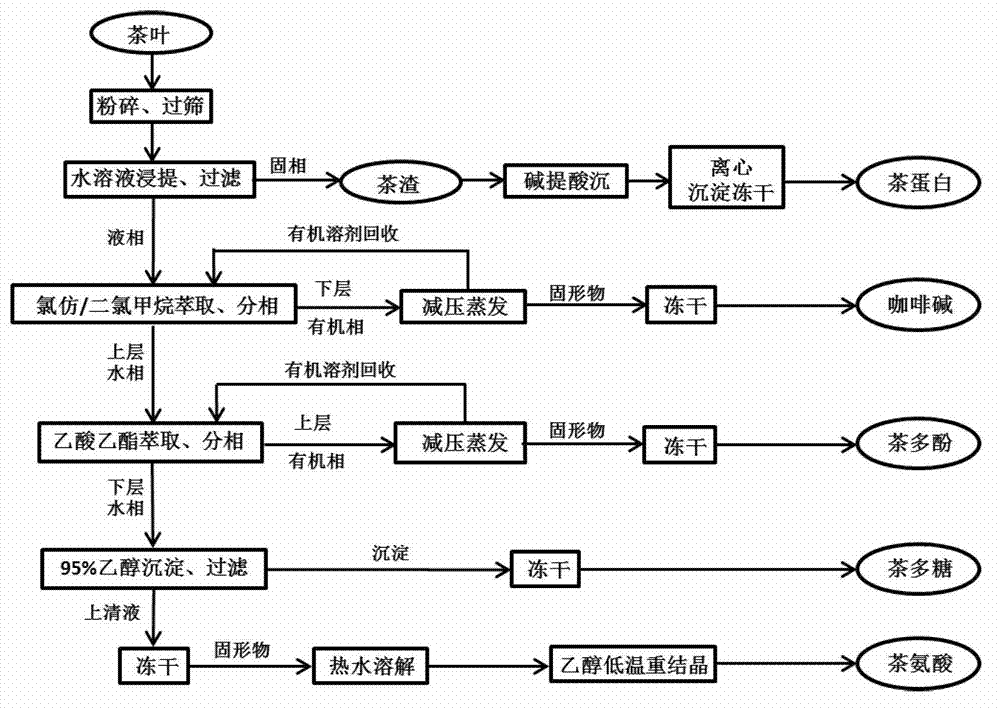

A technology for comprehensive extraction of active ingredients, which is applied in the field of comprehensive extraction of active ingredients in tea and efficient preparation of active ingredients in tea, can solve problems such as extraction of tea protein, improve utilization rate and production efficiency, and make the production process efficient and environmentally friendly. The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Weak acidic aqueous solution extraction of active ingredients of tea

[0033] Dedust and pulverize the dried tea leaves, and pass through a 60-80 mesh sieve. Take 10g of 60-80 mesh tea powder, add 150mL of phosphate buffer solution with a pH of 5, and then place the system in a constant temperature water bath with a temperature of 50°C to shake and extract. After extracting for 30 minutes, filter, collect tea dregs and dry them. Serum for later use.

[0034] (2) Extraction of tea protein

[0035]Take 5g of the tea residue collected in step (1), add 100mL of alkaline NaOH aqueous solution with a concentration of 0.06mol / L at a solid-to-liquid ratio of 1:20, and place the system in a constant temperature water bath at 70°C Shake and extract for 60 minutes, filter to obtain the alkaline water extract of tea protein; add 0.05mol / L hydrochloric acid to the alkaline water extract of tea protein, adjust the pH to 4.5 for precipitation, centrifuge to remove the supernatan...

Embodiment 2

[0044] (1) Weak acidic aqueous solution extraction of active ingredients of tea

[0045] Dedust and pulverize the dried tea leaves, and pass through a 60-80 mesh sieve. Take 10g of 60-80 mesh tea powder, add 250mL of phosphate buffer solution with a pH of 5-6, and then place the system in a constant temperature water bath with a temperature of 70°C to shake and extract. After extracting for 40 minutes, filter the tea dregs and add them according to the above steps 250mL of phosphate buffer solution with a pH of 5.5 was extracted once more, the tea dregs were collected by filtration and dried, and the supernatants of the two extractions were combined for later use.

[0046] (2) Extraction of tea protein

[0047] Take 5g of the tea residue collected in step (1), add 150mL of alkaline NaOH aqueous solution with a concentration of 0.08mol / L at a solid-to-liquid ratio of 1:30, and place the system in a constant temperature water bath at 80°C Shake and extract for 90 minutes, filt...

Embodiment 3

[0055] (1) Weak acidic aqueous solution extraction of active ingredients of tea

[0056] Dedust and pulverize the dried tea leaves, and pass through a 60-80 mesh sieve. Take 10g of 60-80 mesh tea powder, add 300mL of phosphate buffer solution with a pH of 5-6, and then place the system in a constant temperature water bath at 80°C to extract by shaking. The 6 phosphate buffer solution was repeatedly extracted twice, filtered, the tea residue was collected and dried, and the supernatants extracted three times were combined for later use.

[0057] (2) Extraction of tea protein

[0058] Take 5g of the tea dregs collected in step (1), add it into 200mL of alkaline NaOH aqueous solution with a concentration of 0.10mol / L at a solid-to-liquid ratio of 1:40, and place the system in a constant temperature water bath with a temperature of 90°C Shake and extract for 120 minutes, filter to obtain the alkaline water extract of tea protein; add 0.10mol / L hydrochloric acid to the alkaline w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com