Film pulverizer with recovery device

A technology of recycling device and shredder, which is applied in plastic recycling, recycling technology, mechanical material recycling, etc. It can solve the problems of crushed film without receiving anything, low utilization value, and inability to achieve the effect of depletion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

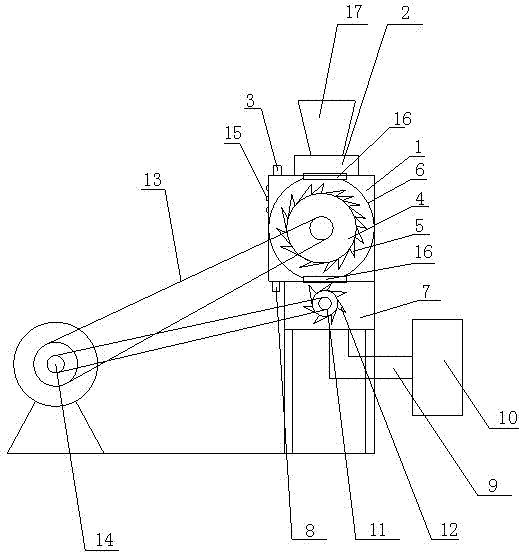

[0013] Such as figure 1 As shown, a film pulverizer with a recovery device of the present invention includes a crushing chamber 1 and a feed port 2, the top of the crushing chamber 1 is provided with a feed port 2, the top of the crushing chamber 1 is provided with a water inlet 3, and the crushing chamber 1 is provided with a water inlet 3. 1. There is a knife holder 4 in the middle of the interior, and a plurality of rotor flying knives 5 are arranged on the knife holder 4. A rotatable circular screen 6 is arranged inside the crushing chamber 1. A discharge chamber 7 and a drainage chamber are arranged at the bottom of the crushing chamber 1. Hole 8, discharge chamber 7 is connected with discharge port 9, discharge port 9 is connected with film recovery device 10, feed port 2 and discharge chamber 7 are all connected with negative air pressure pump 16, and the center of discharge chamber 7 is provided with There is a small knife rest 11, the small knife rest 11 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com