Press mounting device for one-time mounting of differential bearing of forklift

A forklift differential, press-fitting technology, applied in metal processing, metal processing equipment, manufacturing tools and other directions, can solve the problems of unsafe, high labor intensity for handling and turning over, high labor intensity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

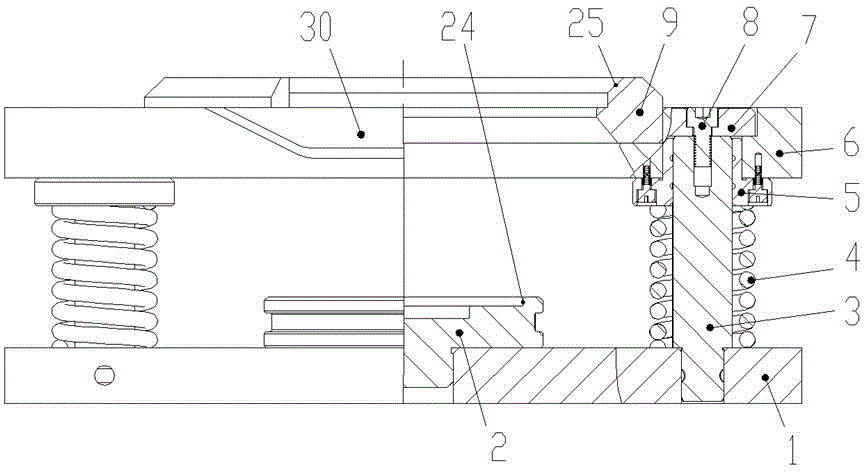

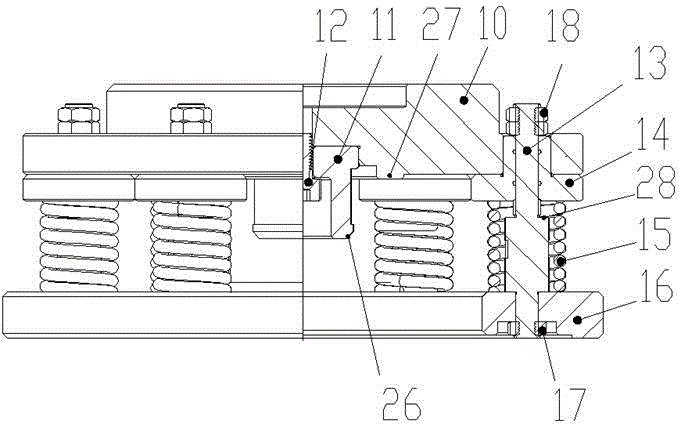

[0023] see figure 1 , The press-fitting device used for one-time installation of forklift differential bearings includes an upper platen mechanism and a lower seat mechanism. see image 3 , The upper platen mechanism includes an upper base plate 10 corresponding up and down, an upper floating platen 16 and six upper guide shafts 13 . The middle part of the upper base plate 10 is provided with an upper positioning shaft hole, and six upper base plate guide holes are evenly distributed around the periphery; the upper floating pressure plate 16 is a ring plate, and six upper floating guide holes are evenly distributed on the circumference, and the upper floating guide holes are upper. Small and large step holes, the lower port is a large port; the upper end of each upper guide shaft 13 is located in the upper base plate guide hole of the upper ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com