Method for determining and optimizing power parameters in manufacturing process of plasma display screen

A plasma display screen and manufacturing process technology, applied in the direction of tube/lamp screen manufacturing, etc., can solve the problems of wasting manpower and kinetic energy consumption costs, large manpower and kinetic energy consumption costs, and reducing production efficiency, so as to save time and resource costs , Improve direction accuracy and reduce scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] A method for determining and optimizing dynamic parameters in a plasma display manufacturing process, comprising the following steps:

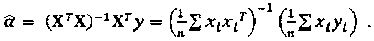

[0019] Step 1. Establish a regression model of important dynamic parameters and yield rate in the plasma display manufacturing process. The specific method is as follows:

[0020] (1) Segment production records in different time periods for three types of dynamic parameters (temperature, humidity, pressure). The specific segmentation methods are as follows:

[0021] 1) Determine the specific time for the product to pass through each piece of equipment during the entire production process;

[0022] 2) Count and record the quantity of products passing through each device and the final quality level of the corresponding products within a set period of time (such as one day or one month);

[0023] 3) Sampling and recording the environmental parameter information of each device, and use this sampling frequency as the basic sampling frequenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com