Working condition-simulating numerically controlled rotary table test-bed loading control system and control method

A technology of CNC turntable and control system, which is applied in control/adjustment system, non-electric variable control, mechanical pressure/force control, etc. It can solve the problem that the performance parameters of CNC turntable cannot be detected, and the most critical dynamic parameters of CNC turntable performance cannot be effectively performed. The measurement, the failure to determine the CNC turntable and other problems, achieve the effect of superior performance, light weight and large bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

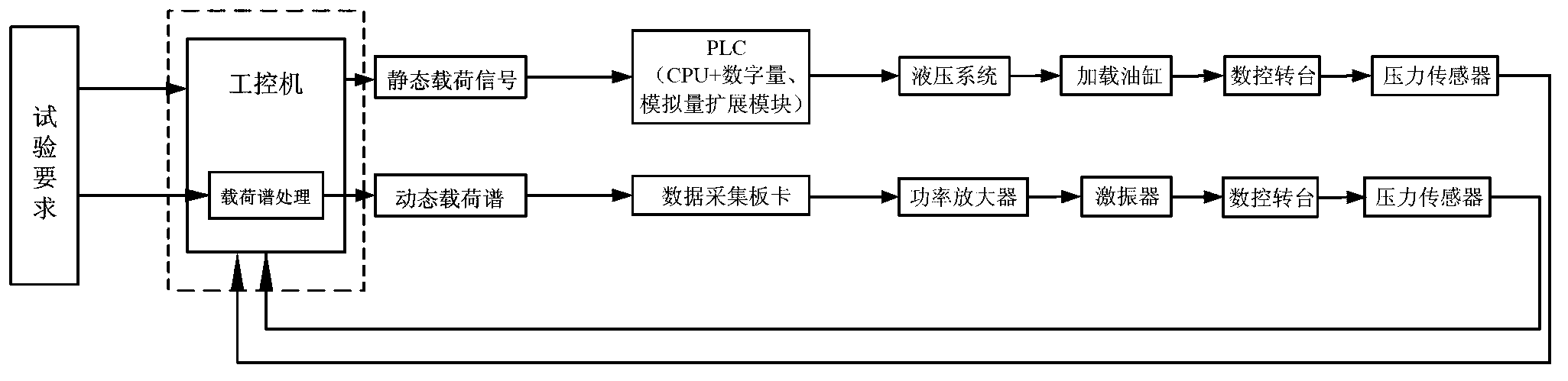

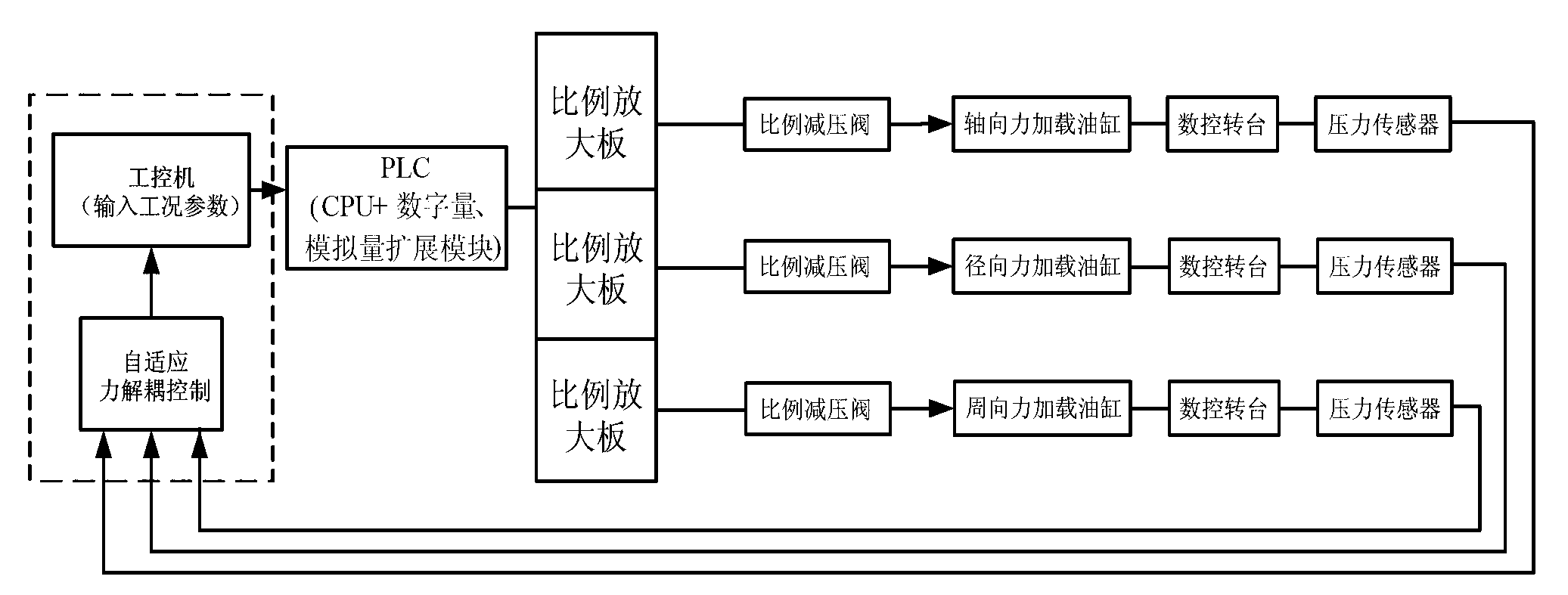

[0031] A numerically controlled turntable test bench load loading control system for simulating working conditions, characterized in that it includes a hydraulic loading system for simulating static loads, an excitation system for simulating dynamic loads, and a control system for simulating loading of loads, and the hydraulic pressure for simulating static loads The loading system includes a motor, a variable vane pump, a proportional pressure reducing valve and an electromagnetic reversing valve, and thus forms a pressure-adjustable and controllable hydraulic loading circuit; the vibration system for simulating dynamic loads includes a power amplifier, a high-energy vibration exciter and a pressure sensor; the load simulation loading control system includes an upper computer, an industrial computer and a PLC lower computer.

[0032] The hydraulic loading system for simulating static load also includes a fuel tank, an air filter, a liquid level gauge, an oil suction filter, a ...

Embodiment 2

[0037] A numerically controlled turntable test bench load loading control system for simulating working conditions, characterized in that it includes a hydraulic loading system for simulating static loads, an excitation system for simulating dynamic loads, and a control system for simulating loading of loads, and the hydraulic pressure for simulating static loads The loading system includes a motor, a variable vane pump, a proportional pressure reducing valve and an electromagnetic reversing valve, and thus forms a pressure-adjustable and controllable hydraulic loading circuit; the vibration system for simulating dynamic loads includes a power amplifier, a high-energy vibration exciter and a pressure sensor; the load simulation loading control system includes an upper computer, an industrial computer and a PLC lower computer.

[0038] The hydraulic loading system for simulating static load also includes a fuel tank, an air filter, a liquid level gauge, an oil suction filter, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com