Detection jig for back plates of display screen

A technology for detecting fixtures and display screens, applied in measuring devices, mechanical measuring devices, mechanical diameter measurement, etc., which can solve the problems of complicated measurement process and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical solutions, technical features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

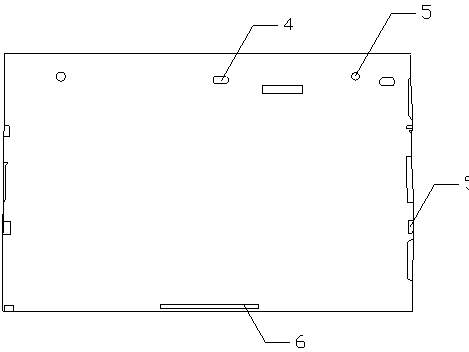

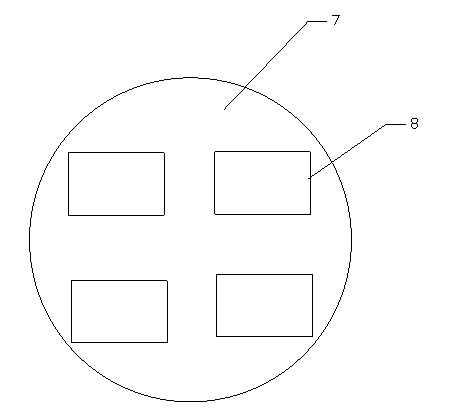

[0018] according to Figure 1-Figure 3 , the detection fixture of the display screen backplane is characterized in that: the detection fixture is a hollow structure, and several protrusions 6, depressions 4 and solid parts 5 that cooperate with the backplane 8 are arranged around the detection fixture, and the detection that can move up and down The jig is placed above the rotatable round platform 7 . The protrusion 6 cooperates with the recessed part 3 of the backboard 8 , the said depression 4 cooperates with the raised part 2 of the backboard 8 , and the said solid part 5 cooperates with the hole 1 of the backboard 8 . A number of backboards 8 to be detected are placed on the rotatable round table 7, and several backboards 8 to be detecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com