Fabricated prestressed honeycomb web steel beam

A prestressed, honeycomb-shaped technology, applied in the direction of joists, girders, truss beams, etc., can solve problems such as the need to improve the shear bearing capacity, affect the mechanical performance of components, and the effect is not very ideal, to achieve excellent out-of-plane stiffness, Improve the effect of mechanical performance and mechanical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention is further illustrated below by means of embodiments in conjunction with the accompanying drawings.

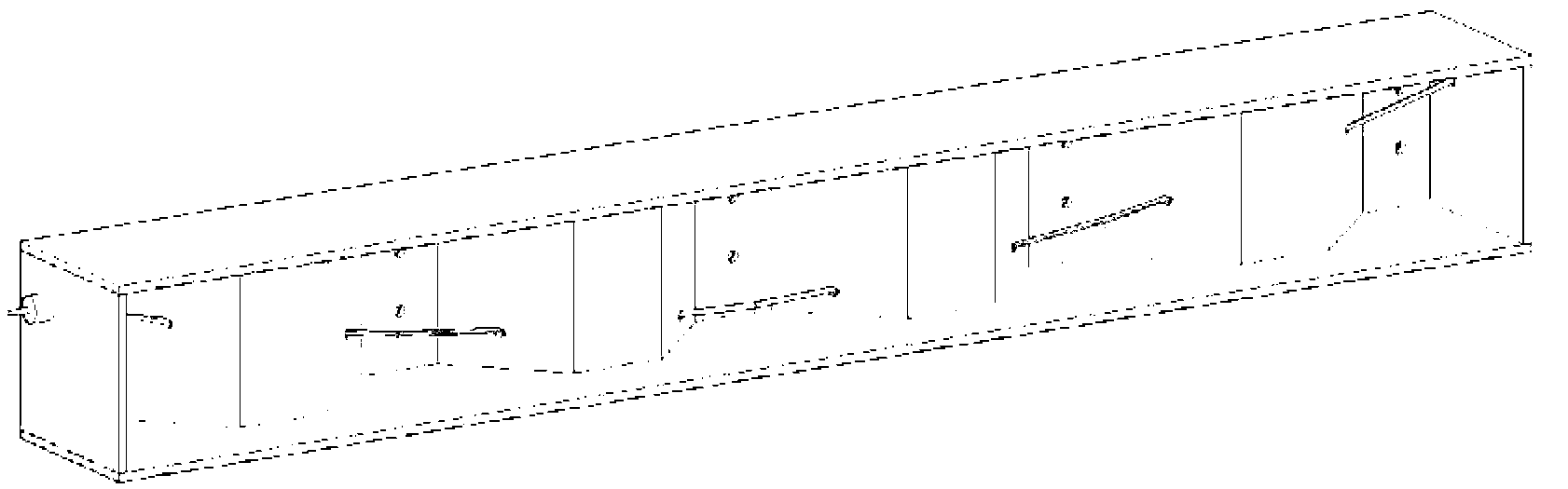

[0042] as attached Figure 1-2 As shown, the assembled prestressed honeycomb web steel girder proposed by the present invention is assembled by two prestressed corrugated web channel steel girders 1 through bolts 6, and the two prestressed corrugated web channel steel girders 1 web The butt joint is assembled and connected at the bolt hole 5 by using the bolt 6 at the web.

[0043] as attached Figure 3-4 As shown, the prestressed corrugated web channel steel girder 1 includes an upper flange 2, a web 3, a lower flange 4, a prestressed cable 7, an anchor 9 and a beam end plate 10; Flange 2, web 3 and lower flange 4, the upper flange 2 is parallel to the lower flange 4, the web 3 is vertically located between the upper flange 2 and the lower flange 4, and the web 3 is provided with Bolt holes 5 and prestressed cable holes 8.

[0044] as attached...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com