Method for continuously preparing silkworm chrysalis protein antioxidant peptides by using enzyme membrane reactor

A technology of enzyme membrane reactor and silkworm chrysalis protein, which is applied in the field of food biochemistry, can solve the problems of high labor intensity, long production cycle, and low utilization rate of protease, and achieve the effects of reducing labor intensity, avoiding activity reduction, and improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

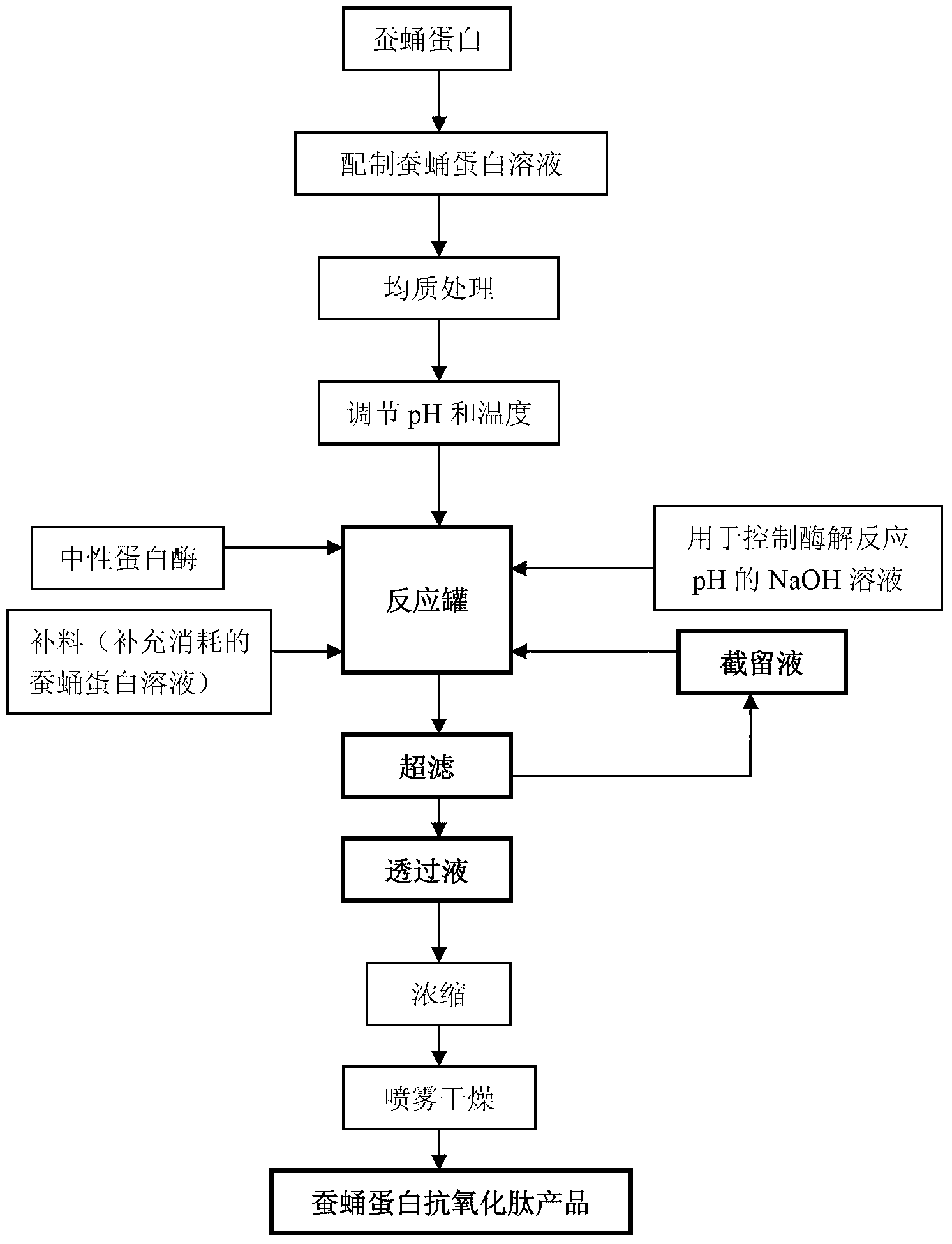

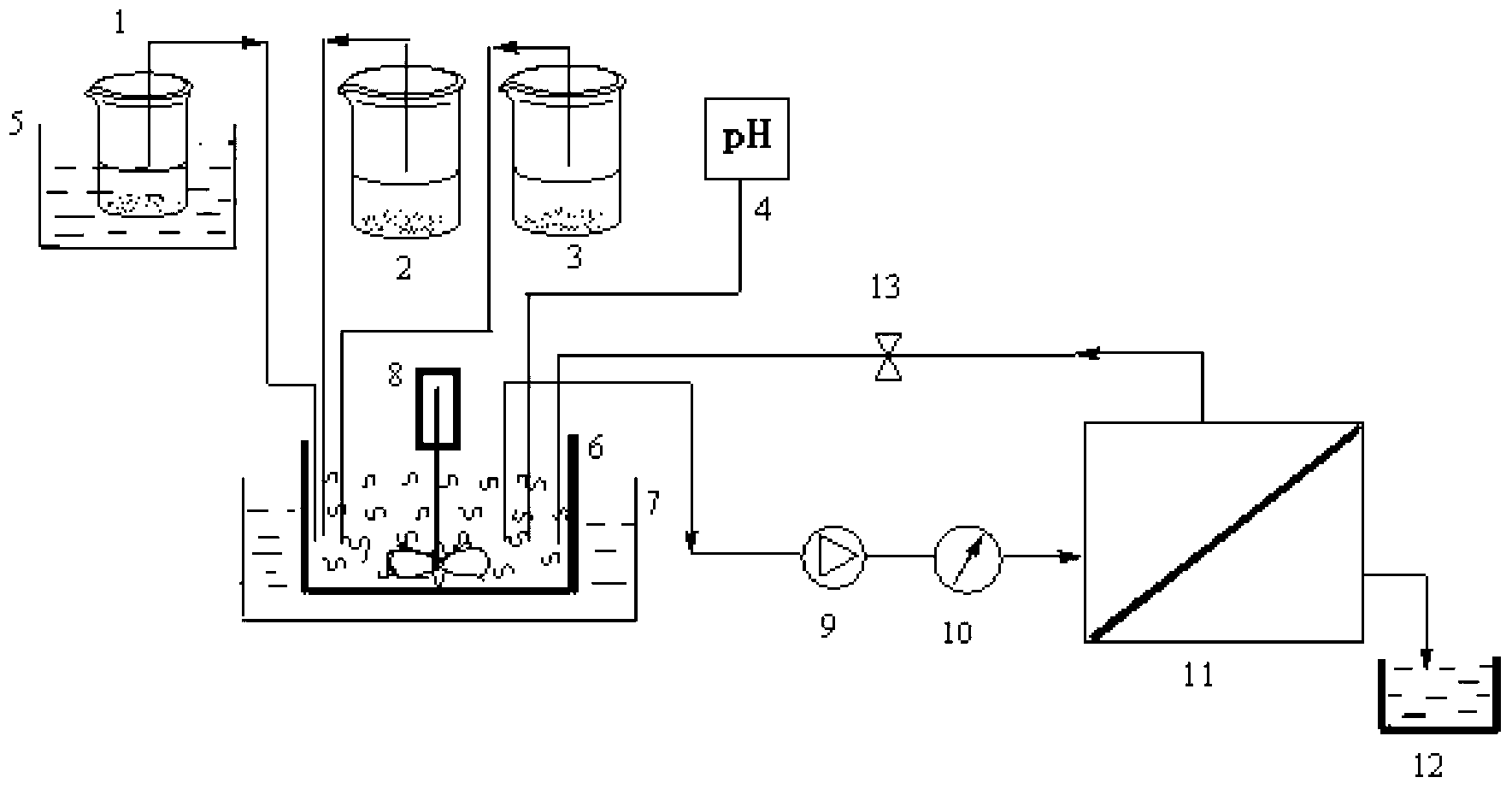

Method used

Image

Examples

Embodiment 1

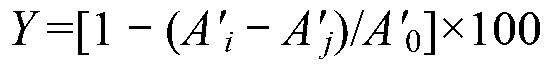

[0035] Prepare silkworm chrysalis protein into a 1.0% (w / v, g / mL) solution with distilled water, adjust its pH to 6.0 after homogenization, heat to 40°C and add it into the reaction tank together with neutral protease, stir evenly and carry out enzyme Membrane reaction, the amount of enzyme added is 2000U / g, the pH is 6.0, the temperature is 40°C, the molecular weight cut-off of the ultrafiltration membrane is 3kDa, and the ultrafiltration pressure is 0.6kg / cm 2 , the peptide output rate is 6mL / min; the enzymatic hydrolysis product solution passes through the ultrafiltration membrane, the incompletely reacted silkworm chrysalis protein and neutral protease are intercepted and flow back to the reaction tank to continue the reaction, and the enzymatic hydrolysis product passing through the ultrafiltration membrane The permeate is collected; at the same time, according to the concentration of the peptide in the permeate of the enzymatic hydrolysis product during the enzyme membran...

Embodiment 2

[0037] Prepare silkworm chrysalis protein into a 2.0% (w / v, g / mL) solution with distilled water, adjust its pH to 6.5 after homogenization, add it into the reaction tank together with neutral protease after heating to 50°C, and perform enzyme Membrane reaction, the amount of enzyme added is 4000U / g, the pH is 6.5, the temperature is 50°C, the molecular weight cut-off of the ultrafiltration membrane is 5kDa, and the ultrafiltration pressure is 0.8kg / cm 2 , the peptide output rate is 5mL / min; the enzymatic hydrolysis product solution passes through the ultrafiltration membrane, the incompletely reacted silkworm chrysalis protein and neutral protease are intercepted and flow back to the reaction tank to continue the reaction, and the enzymatic hydrolysis product passing through the ultrafiltration membrane The permeate is collected; at the same time, according to the concentration of peptide in the permeate of the enzymolysis product during the enzyme membrane reaction, the same c...

Embodiment 3

[0039] Prepare silkworm chrysalis protein into a 4.0% (w / v, g / mL) solution with distilled water, adjust its pH to 7.5 after homogenization, add it into the reaction tank together with neutral protease after heating to 60°C, stir evenly, and perform enzyme Membrane reaction, the amount of enzyme added is 6000U / g, the pH is 7.5, the temperature is 60°C, the molecular weight cut-off of the ultrafiltration membrane is 10kDa, and the ultrafiltration pressure is 0.9kg / cm 2 , the peptide output rate is 4mL / min; the enzymatic hydrolysis product solution passes through the ultrafiltration membrane, the incompletely reacted silkworm chrysalis protein and neutral protease are intercepted and flow back to the reaction tank to continue the reaction, and the enzymatic hydrolysis product passing through the ultrafiltration membrane The permeate is collected; at the same time, according to the concentration of peptide in the permeate of the enzymolysis product during the enzyme membrane reacti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com