Corporate aircraft engine upper placement and front swept wing duck type layout

A technology of engines and business jets, which is applied in the aviation field, can solve the problems of increasing the airflow velocity on the lower surface of the wing and reducing the lift of the wing, so as to achieve the effect of ensuring the control efficiency of the rudder surface, small wing area and long range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

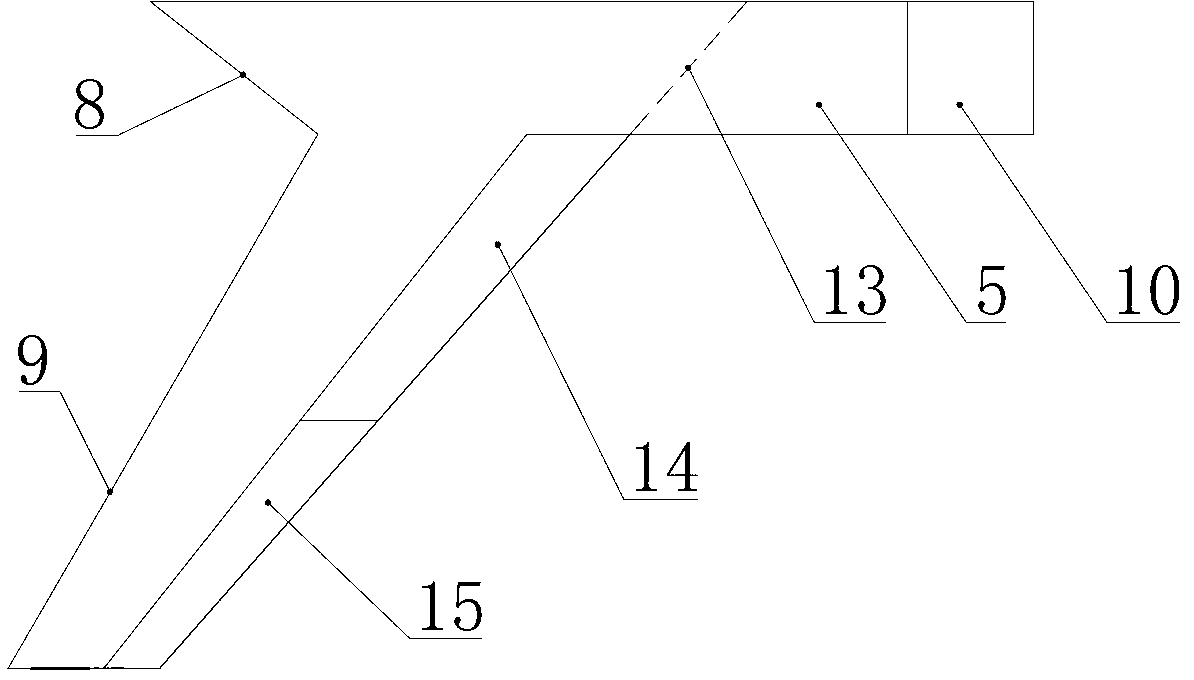

[0025] (1) The aircraft is mainly composed of fuselage 2, canard 7, wing 1, vertical tail 3, engine 4 and rear body strip 5, in which the engine 4 is supported on the rear body edge near the rear edge of the wing through the engine bracket 6 On the upper surface of the bar 5, an elevator 16 is arranged on the rear edge of the canard 7, an inner elevon 14 is arranged on the inner side of the rear edge of the wing, an outer elevon 15 is arranged on the outer side, and a side rudder 10 is arranged on the rear edge of the rear body side bar 5. , the rear edge of the vertical tail 3 is arranged with a rudder 13, see figure 1 ,

[0026] (2) The inner section 8 of the leading edge of the wing is swept back, the outer section 9 of the leading edge is swept forward, and the inner section 17 of the trailing edge of the wing is connected with the side strip 5 of the rear body, see figure 2 ;

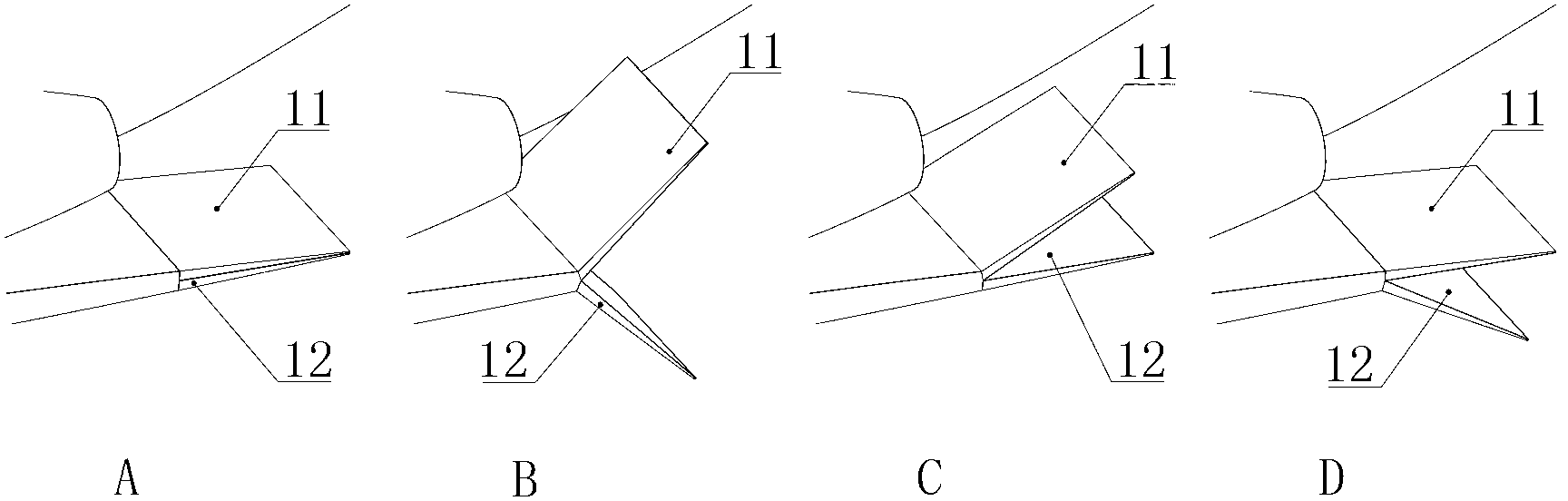

[0027] (3) The side bar rudder 10 at the rear edge of the rear body side bar 5 is a split de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com