Preparation method for hollow nano metal

A hollow nano-metal technology, which is applied in the preparation of microspheres, microcapsule preparations, etc., can solve the problems of difficult adjustment of the size of hollow nano-metals, poor shape and monodispersity of hollow nano-metals, etc. Low price, good monodispersity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

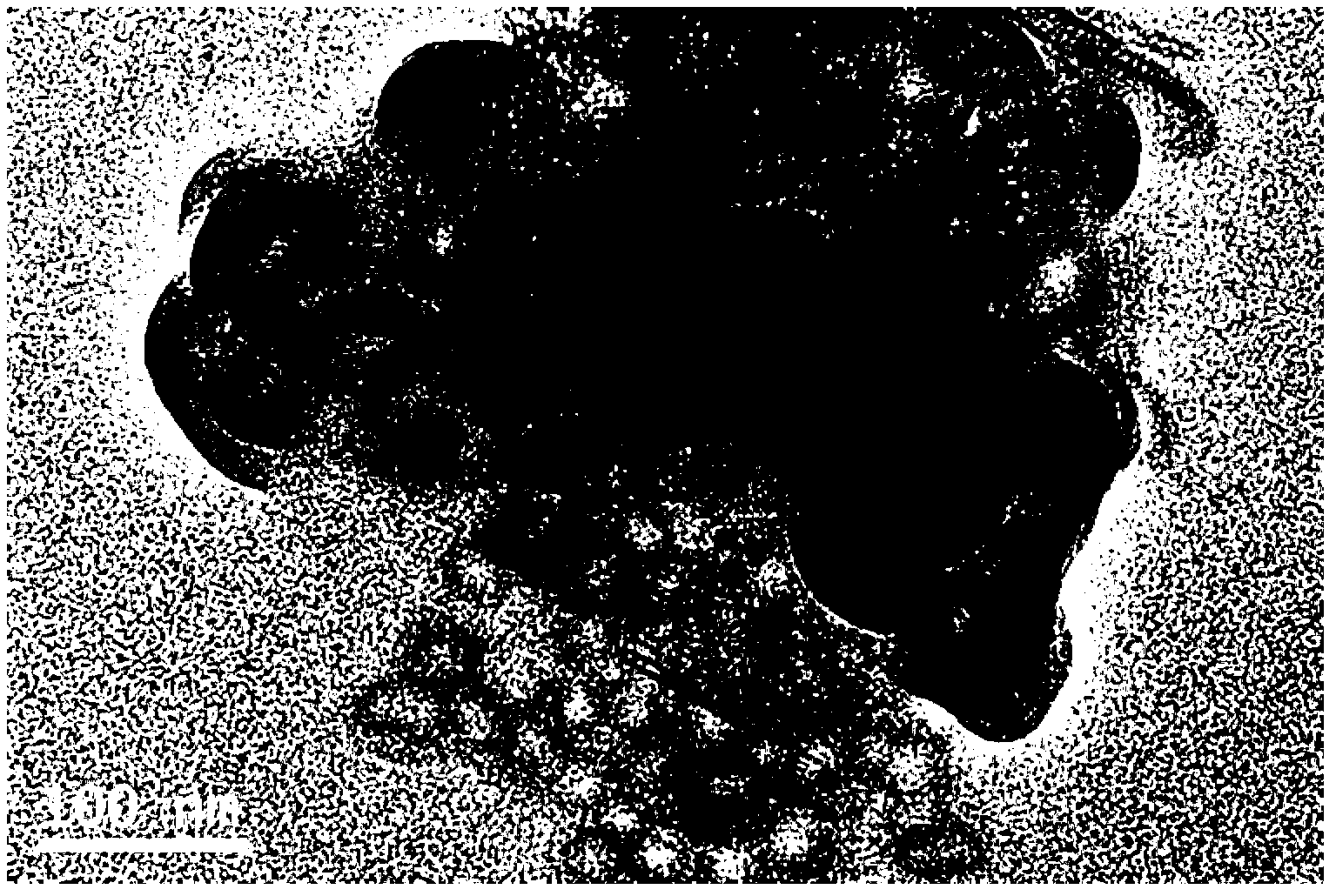

[0025] Dissolve 0.2 g of glucose in 10 g of water, pour it into a three-necked flask, add 1 g of AOT and 100 ml of benzene, put it into the rotor, put the three-necked flask into an oil bath and stir. Raise the temperature of the oil bath to 100°C until the system is clear. Weigh 0.14 g of triphenylphosphine and dissolve it in 2 ml of benzene, then add 0.05 g of silver nitrate for complexation, complex the silver nitrate and triphenylphosphine, and then add it to a clear solution at 70°C for reaction. After reacting for 6 hours, take out the sample. After being centrifuged at 10,000 rpm by a centrifuge, the precipitate was taken, and the glucose was washed away with water and then centrifuged to obtain spherical hollow nano-silver. The average size of the hollow silver nanoparticles is 30nm, and the wall thickness is 2nm. Microemulsion-assisted preparation of hollow silver nanoparticles transmission electron microscope images such as figure 1 shown. figure 2 It is the XRD ...

Embodiment example 2

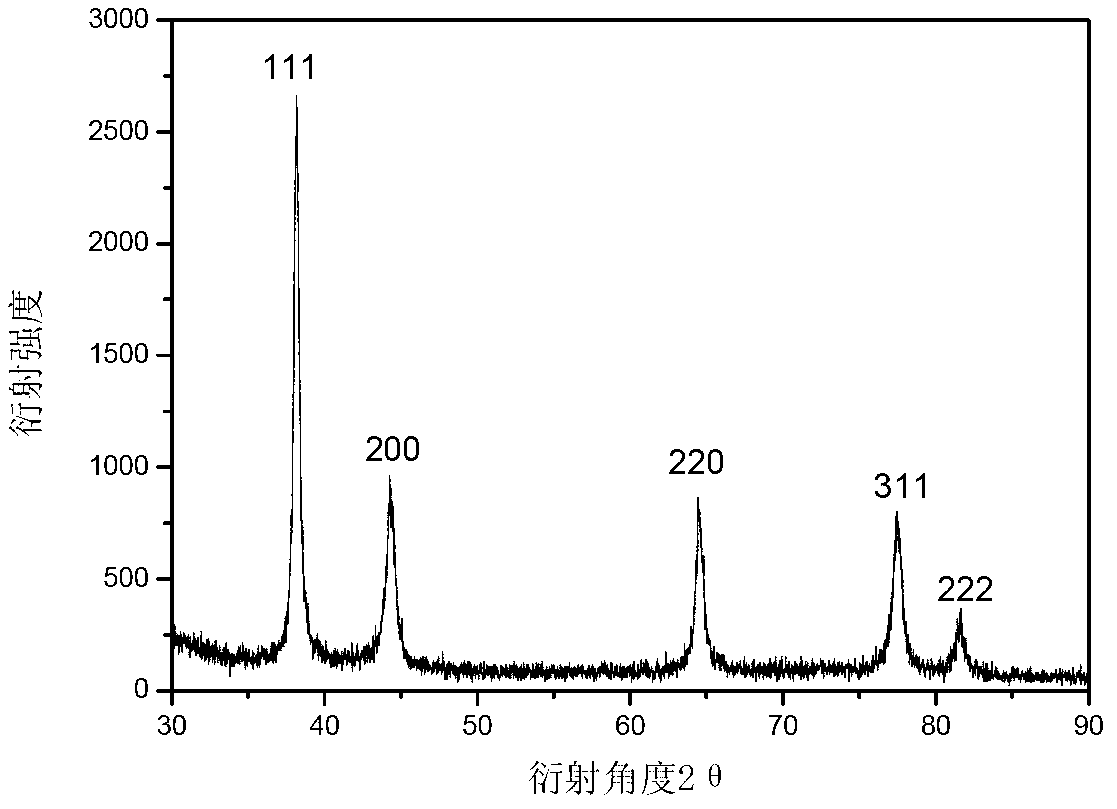

[0027] Dissolve 0.4 g of glucose in 2 g of water, pour it into a three-necked flask, add 0.78 g of n-octylamine and 16 ml of petroleum ether, put it into the rotor, put the three-necked flask into an oil bath and stir. Raise the temperature of the oil bath to 60°C and azeotrope until the system is clear. Weigh 0.17 grams of silver nitrate, complex the silver nitrate with 1.56 grams of n-octylamine, and add it to the clear solution at 0°C. After reacting for 3 hours, take out the sample, centrifuge at 8500 rpm in a centrifuge, and get the precipitate. Glucose was washed away with water and then centrifuged to obtain cubic hollow nano-silver. The average size of the hollow silver nanoparticles is 200nm, and the wall thickness is 50nm. image 3 is the TEM image of cubic hollow silver nanoparticles. Figure 4 It is the XRD spectrum of cubic hollow nano silver. The XRD pattern shows five obvious absorption peaks of nano-silver, corresponding to (111), (200), (220), (311), (222) ...

Embodiment 3

[0030] Dissolve 1 gram of fructose in 10 grams of water, pour it into a three-necked flask, add 0.1 gram of AOT and 100ml of benzene, put it into the rotor, put the three-necked flask into an oil bath and stir. Raise the temperature of the oil bath to 20°C and azeotrope until the system is clear. Weigh 0.05 g of chloroauric acid, complex the chloroauric acid with 0.1 gram of triphenylphosphine and add it to a clear solution at 80 ° C. After reacting for 3 hours, take out the sample and centrifuge at 12000 rpm to get the precipitate. Fructose was washed away with water and then centrifuged to obtain spherical hollow gold nanoparticles. The average diameter of the hollow gold nanoparticles is 100nm, and the wall thickness is 10nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com