Circular orbit forming mold

A technology for forming molds and circular rails, which is applied in manufacturing tools, metal processing equipment, groove needles, etc., and can solve problems such as shortening the life of related mechanisms.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

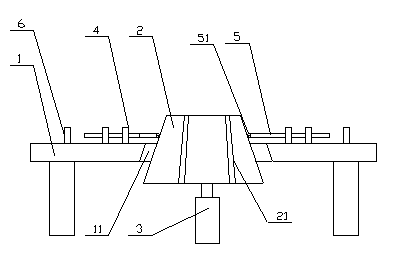

[0010] The circular track molding die includes a platen 1, a truncated cone body 2, a jacking mechanism 3, several guide pieces 4, a pressure column 5 and a limit plate 6, a circular hole 11 is provided in the middle of the platen 1, and the truncated cone body 2 is located on the In the round hole, the jacking mechanism 3 is driven and connected with the frustum of conical body 2, the limit plate 6 is evenly distributed on the side of the platen along a circumferential direction, and the guide piece 4 and the limit plate 6 are correspondingly arranged on a smaller circle, guiding There is a guide hole (not shown in the figure) in the middle of the plate, and the pressure column is slidably arranged in the guide hole. One end of the pressure column 5 is provided with a roller 51 for rolling. The channel 21 is connected in contact. The jacking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com