Diethylene glycol monomethyl ether resistant coating

一种涂料、硫醇的技术,应用在环氧树脂涂料、聚脲/聚氨酯涂料、涂层等方向,能够解决没有提供足够耐酸性耐微生物副产物性、消耗飞机燃料系统塑料和橡胶组分、产生酸性代谢副产物等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

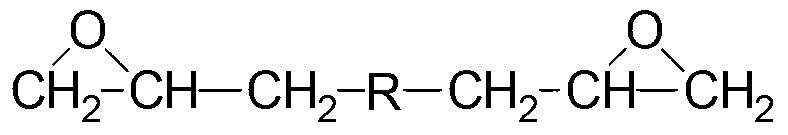

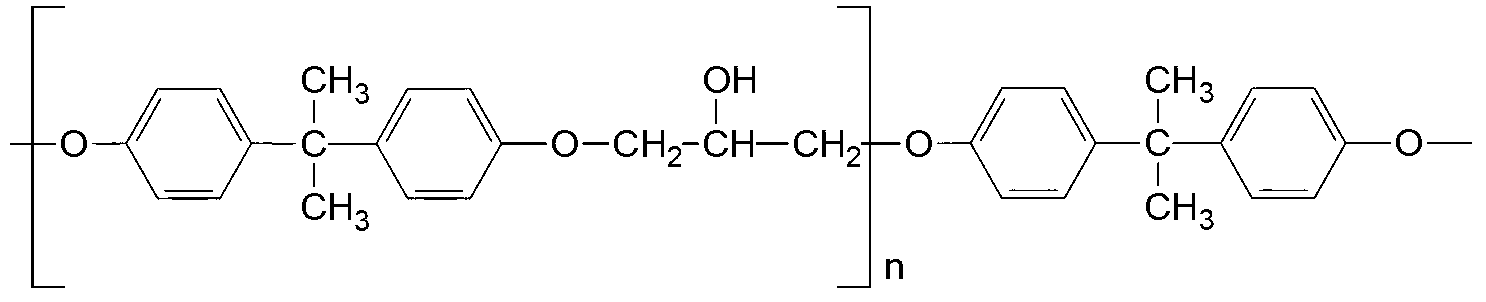

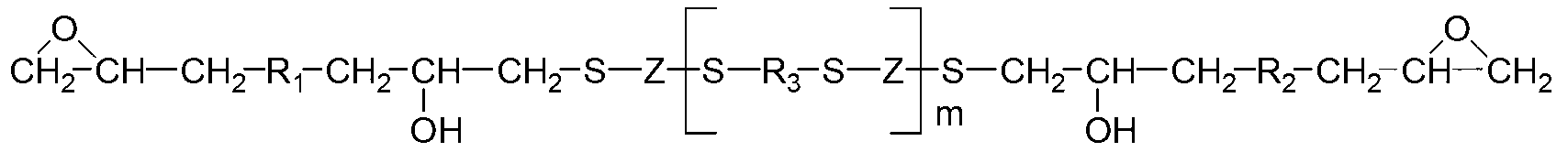

[0165] Example 1: Synthesis of polysulfide containing polyol

[0166] The reaction between epoxy resin (Epon1001F) and thiol-terminated polysulfide (Permapol P-3.1E) is carried out at 125-130°C. The ratio of epoxy equivalent to mercaptan equivalent is approximately 3.5:1.0. The amount of each reactant is listed in Table 1 below. The reaction is monitored by thiol equivalent titration, and a high thiol equivalent indicates completion of the reaction. A polysulfide solution containing polyol with the following properties was obtained: NVM: 70.0%, weight / gallon (WPG): 8.96 lb / gal, OH equivalent (theoretical): 1141 at 70% NVM, mercaptan equivalent : At 70% NVM, it is 1803917.

[0167] Table 1

[0168] Preparation of sulfur-containing epoxy functionalized polyol

[0169]

Embodiment 2

[0170] Example 2: Synthesis of polysulfide containing polyol

[0171] The reaction between epoxy resin (Epon1001F) and thiol-terminated polysulfide Thioplast G-1 is carried out at 125-130°C. The ratio of epoxy equivalent to mercaptan equivalent is 3.5:1.0. The amounts of reactants are listed in Table 2 below. The reaction is monitored by thiol equivalent titration, and a high thiol equivalent indicates completion of the reaction. A polysulfide solution containing polyol with the following properties was obtained: NVM: 70.0%, WPG: 8.96 lb / gal, OH equivalent (theoretical): 1141 at 70% NVM, and mercaptan equivalent: at 70% NVM It is 1283800.

[0172] Table 2

[0173] Preparation of sulfur-containing epoxy functionalized polyol

[0174]

Embodiment 3

[0175] Example 3: Polysulfide coating formulation

[0176] The sulfur-containing, epoxy-functionalized polyol prepared according to Example 1 was used to prepare the coating composition. The amounts of sulfur-containing, epoxy-functionalized polyol and other components of the coating composition are listed in Table 3.

[0177] table 3

[0178] Preparation of DIEGME fuel tank paint

[0179]

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight-average molecular weight | aaaaa | aaaaa |

| weight-average molecular weight | aaaaa | aaaaa |

| weight-average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com