LED light source improvement method and LED light source

A technology of LED light sources and LED lamp beads, which is applied in the field of LED light sources, can solve the problems of low utilization rate of LED lamp beads and poor uniformity of light sources, and achieve the effect of increasing utilization rate and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

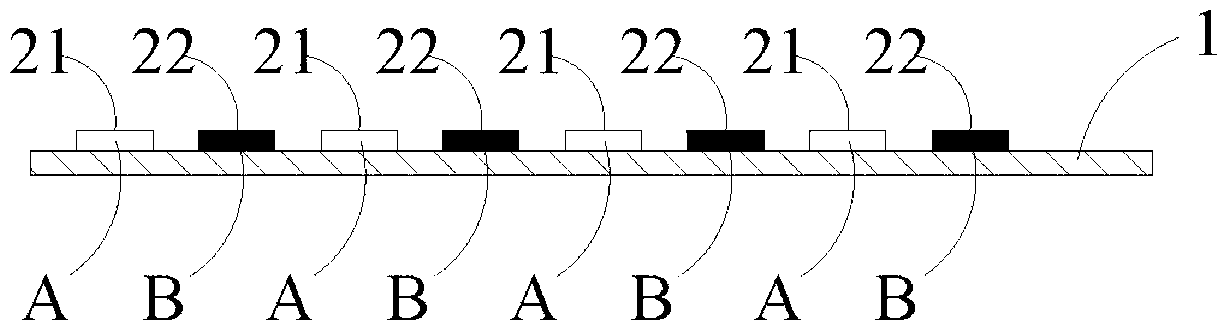

Embodiment 1

[0025] In the design of LCD backlight modules, usually based on the minimum brightness and central chromaticity requirements required by the backlight module, the minimum required LED light source can be easily estimated by considering factors such as the brightness enhancement factor of the optical film and the light loss of the light guide plate. The total brightness and central chromaticity, and then divided by the total number of LED lamps arranged under ideal conditions, can estimate the minimum brightness and central chromaticity requirements of each LED lamp bead, assuming that the minimum brightness of the LED lamp bead is required to be L=36LM, center color coordinates (x,y)=(0.26,0.22). At present, the common practice of backlight modules is to use LED lamp beads of the same specification with the minimum brightness of L=36LM and the center color coordinates (x, y)=(0.26, 0.22) to be arranged at equal intervals, resulting in LED lamp bead utilization. Low, poor unifo...

Embodiment 2

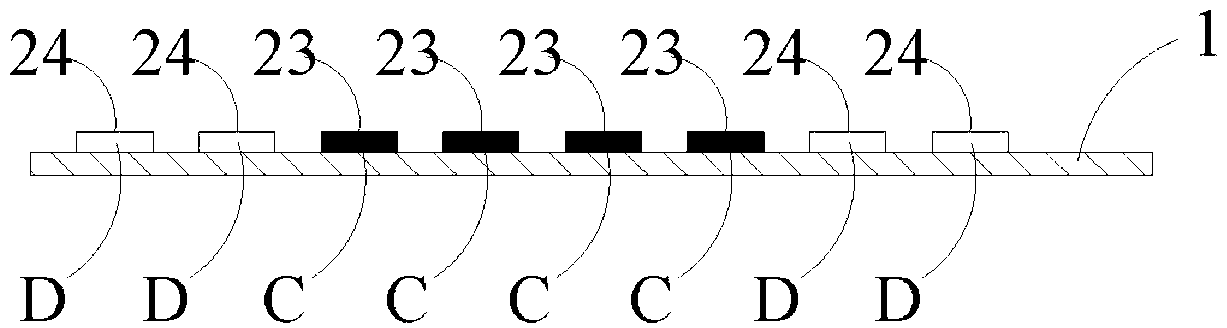

[0035] Please refer to figure 2 The difference between this embodiment and the first embodiment is that in order to improve the light uniformity of the backlight module, the brightness of each LED light bead on the substrate 1 when it is working normally is changed from the light-emitting area located in the center of the substrate to the peripheral area located on the substrate. The luminescent area increases sequentially. In this embodiment, the LED lamp beads of the two kinds of specifications adopt the brightness L 1 =35LM, color coordinates (x 1 ,y 1 )=(0.27,0.23) LED lamp bead 23 and brightness L 2 =37LM, color coordinates (x 2 ,y 2 )=(0.25,0.21) LED lamp bead 24. Divide the substrate 1 into 8 light-emitting areas connected in parallel, and the same light-emitting area is provided with LED lamp beads with the same specifications; the four light-emitting areas located in the center are provided with LED lamps with relatively low luminance during normal operation B...

Embodiment 3

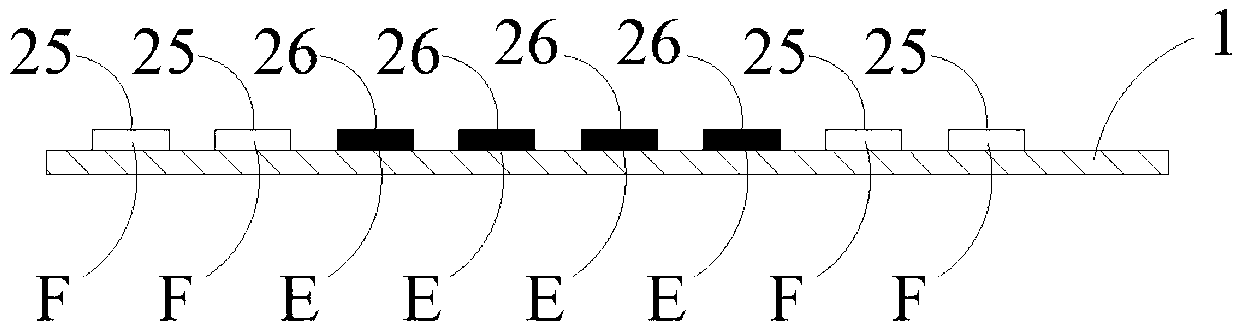

[0038] Please refer to image 3 The difference between this embodiment and the second embodiment is that in order to improve the central brightness of the backlight module, the brightness of each LED lamp bead on the substrate 1 when it is working normally is changed from the light-emitting area located in the center of the substrate to the LED lamp beads located in the peripheral area of the substrate. The luminous area decreases successively. In this embodiment, the LED lamp beads of the two kinds of specifications adopt the brightness L 1 =35LM, color coordinates (x 1 ,y 1 )=(0.27,0.23) LED lamp bead 25 and brightness L 2 =37LM, color coordinates (x 2 ,y 2 )=(0.25,0.21) LED lamp bead 26. Divide the substrate 1 into 8 light-emitting areas connected in parallel, and the same light-emitting area is provided with LED lamp beads with the same specifications; the four light-emitting areas located in the center are provided with LED lamps with relatively high luminous brig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com