Automatic suction and ecological treatment system for polluted bottom sediments of rivers

A technology for ecological treatment and bottom sludge, applied in biological sludge treatment, water/sludge/sewage treatment, sustainable biological treatment, etc. problems, to achieve the effect of no secondary pollution, no operating costs, survival and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with example further illustrate the present invention.

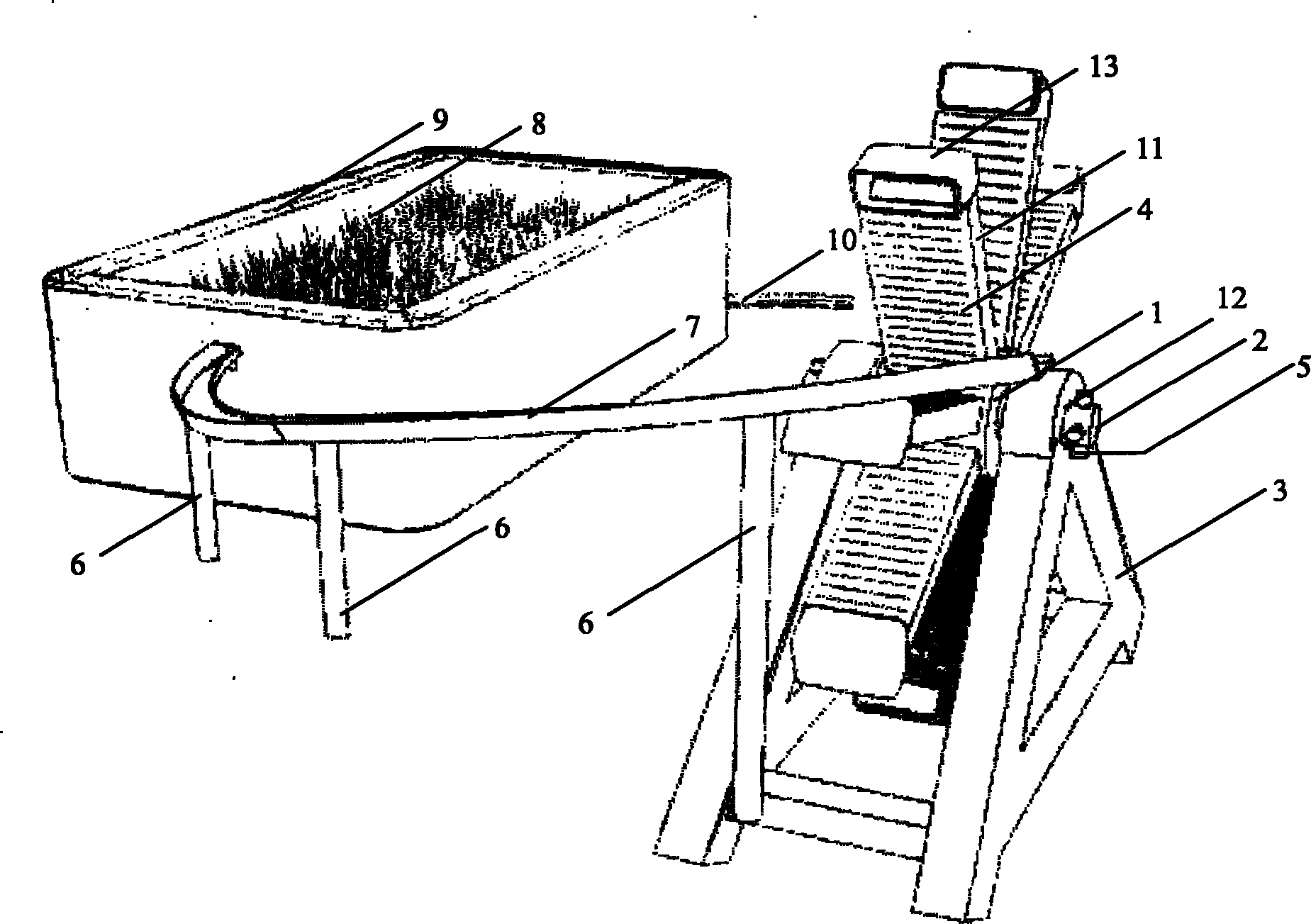

[0019] The main body of the system for automatic suction and ecological treatment of river polluted sediment is a wooden waterwheel with a diameter of 320cm. Install 8 waterwheel blades at 45° on a wooden ring with an outer diameter of 60cm, an inner diameter of 10cm, and a width of 50cm. Each waterwheel blade is 120cm long, 50cm wide, and 5cm thick. 1cm thick activated carbon fiber is laid on both sides. A suction mud bucket is installed perpendicular to the paddle at each paddle top of the waterwheel, and the thickness of the suction mud bucket is 10cm, wide and 50cm, and deeply 20cm. The wooden ring is installed in the opening of the waterwheel bracket at the top of the waterwheel bracket through the waterwheel rotating shaft. The diameter of waterwheel rotating shaft is 10cm, and long is 120cm. The waterwheel support is an isosceles triangle support, the height of the waterwheel support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com