A microwave oven magnetron preheating control method and control circuit

A magnetron preheating and control method technology, which is applied in the microwave oven magnetron control circuit and the microwave oven magnetron preheating control field, can solve the problems of increasing the complexity of the control circuit and inconvenient actual operation, and achieves simple structure and high efficiency. Long service life, uniform heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

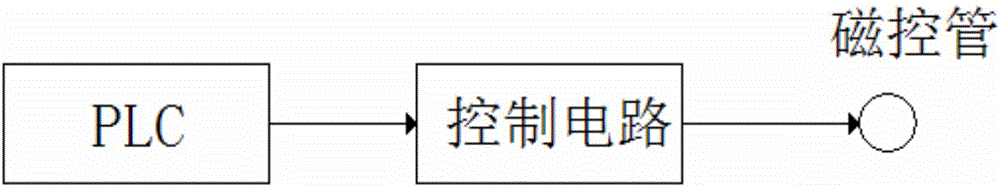

[0021] Embodiment 1: The microwave oven magnetron preheating control method of the present invention, for a microwave heating source composed of n magnetrons, n AC contactors are used to control and connect n magnetrons respectively, and the n AC The contactor is connected to the PLC under control, and the closing and opening of the AC contactor is controlled by programming the output signal of the PLC, so that m of the n magnetrons work first, and the filament of the m+1th magnetron is turned on , to preheat it; then stop the first magnetron every 90 to 200 seconds, start the m+1th magnetron, and start the m+1th magnetron at the same time to make the m+2th magnetron Turn on the filament of the control tube to preheat it; then stop the second magnetron every 90 to 200 seconds, start the m+2 magnetron, and start the m+2 magnetron at the same time The filament of the m+3th magnetron is turned on to preheat it until the nth magnetron is started, and at the same time the filament ...

Embodiment 2

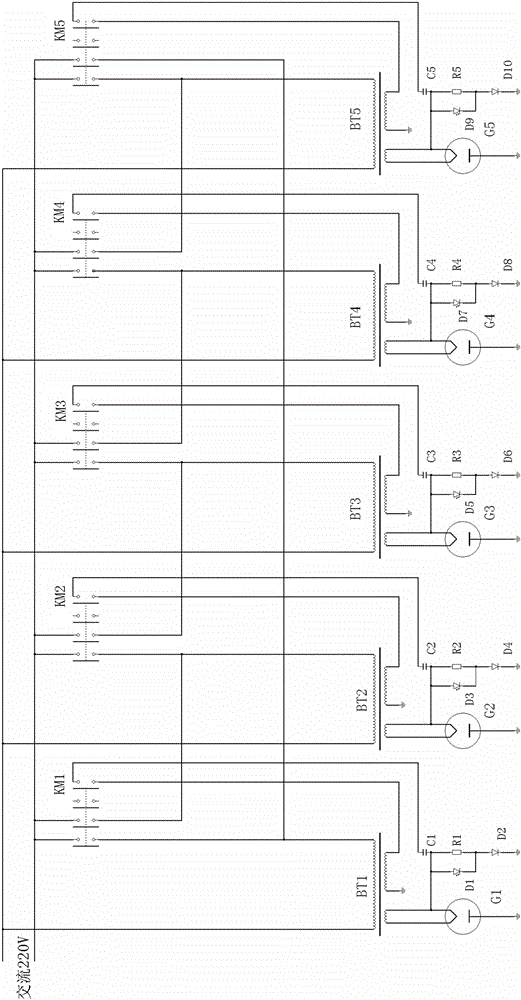

[0022] Embodiment two: see figure 1 , figure 2 , this embodiment is a single-phase microwave oven magnetron control circuit for realizing the preheating control method of microwave oven magnetron as described above, including PLC, n AC contactors, n magnetrons and their power supply circuits, n AC The contactor is correspondingly connected to n magnetrons, and the n AC contactors are respectively controlled and connected to the PLC. The primary winding of the transformer in each magnetron power supply circuit is connected through the first set of normally open contacts of the corresponding AC contactor. power supply, each AC contactor is provided with a third set of normally open contacts connected in series between the secondary high-voltage winding of the transformer in the corresponding magnetron power supply circuit and the voltage doubler rectifier capacitor; at the same time, each AC contactor is provided with The second group of normally open contacts starts from the ...

Embodiment 3

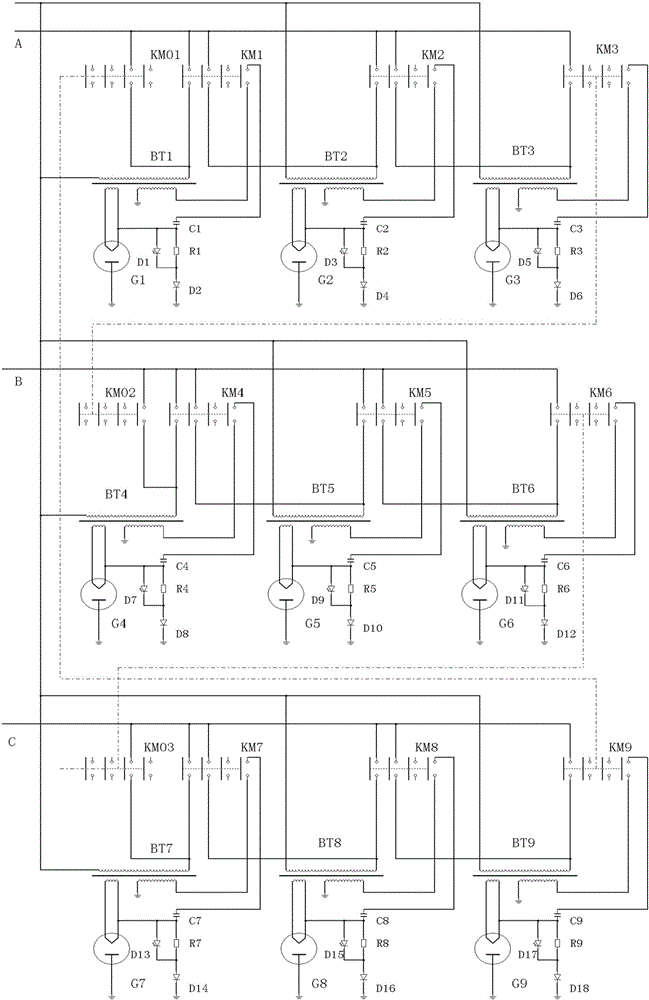

[0030] Embodiment three: see figure 1 , image 3 , the present embodiment is to realize the three-phase microwave oven magnetron control circuit of the microwave oven magnetron preheating control method as described above, including PLC, AC contactor, magnetron and power supply circuit thereof, all connected in each phase power supply There are n AC contactors corresponding to n magnetrons connected to the control, and all AC contactors are controlled and connected to the PLC respectively. In each phase, the primary winding of the transformer in each magnetron power supply circuit passes through the first AC contactor. A group of normally open contacts is connected to the phase power supply, and each AC contactor is provided with a third group of normally open contacts connected in series between the secondary high voltage winding of the transformer in the corresponding magnetron power supply circuit and the voltage doubler rectifier capacitor; At the same time, each AC conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com