Focusing mechanism of monitoring lens

A lens and support base technology, applied in camera, focusing device, installation, etc., can solve the problems of high manufacturing cost, unsuitable automatic focusing of monitoring lens, complex structure, etc., and achieve convenient focusing, high focusing accuracy, and overall simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

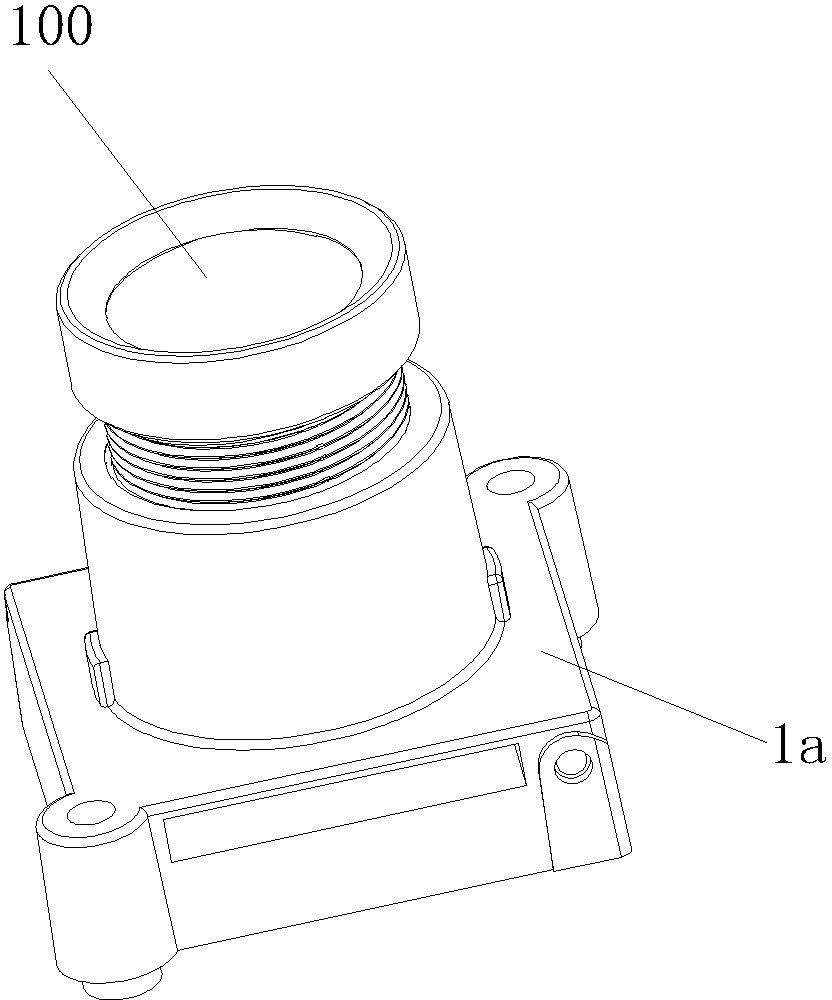

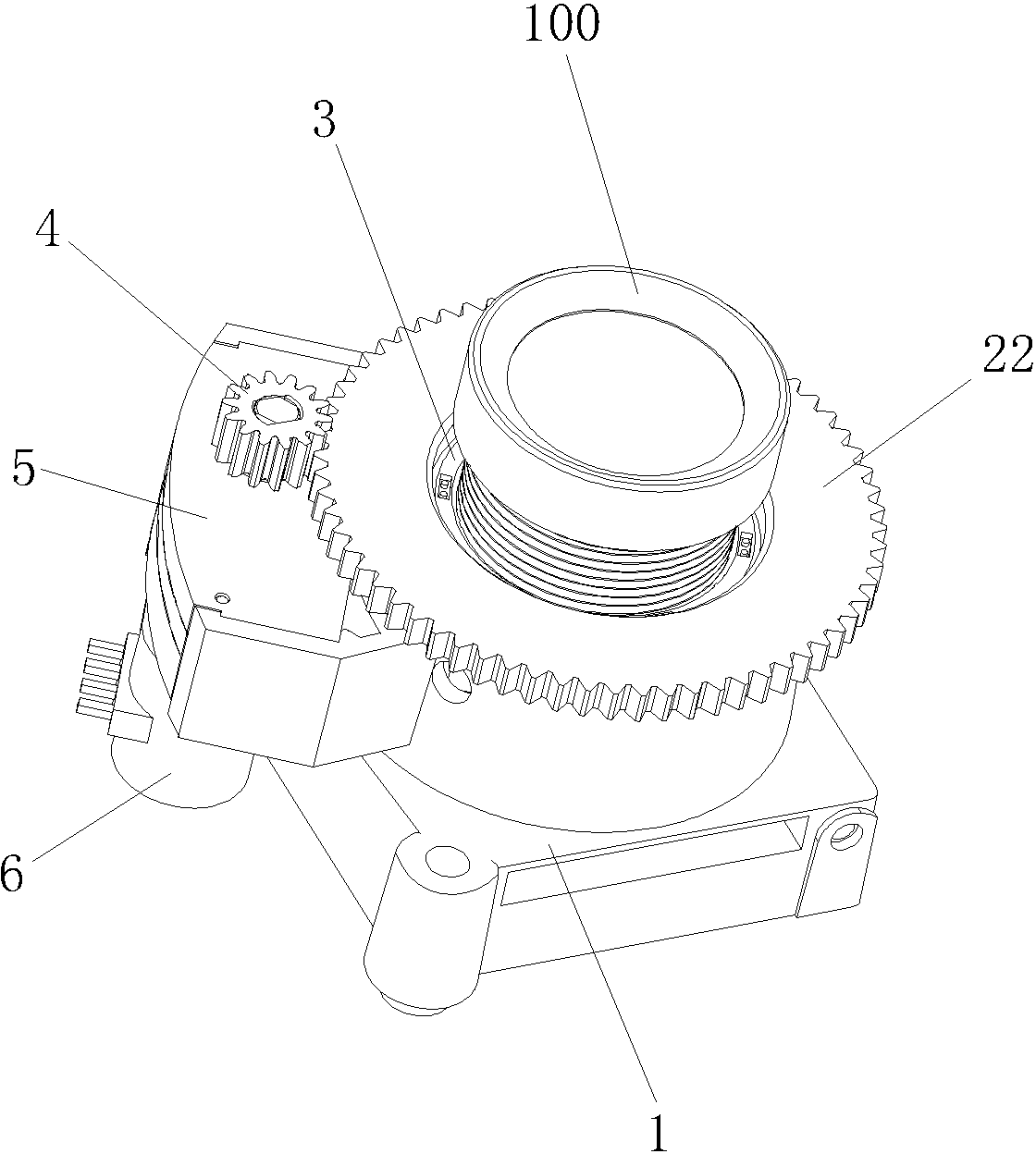

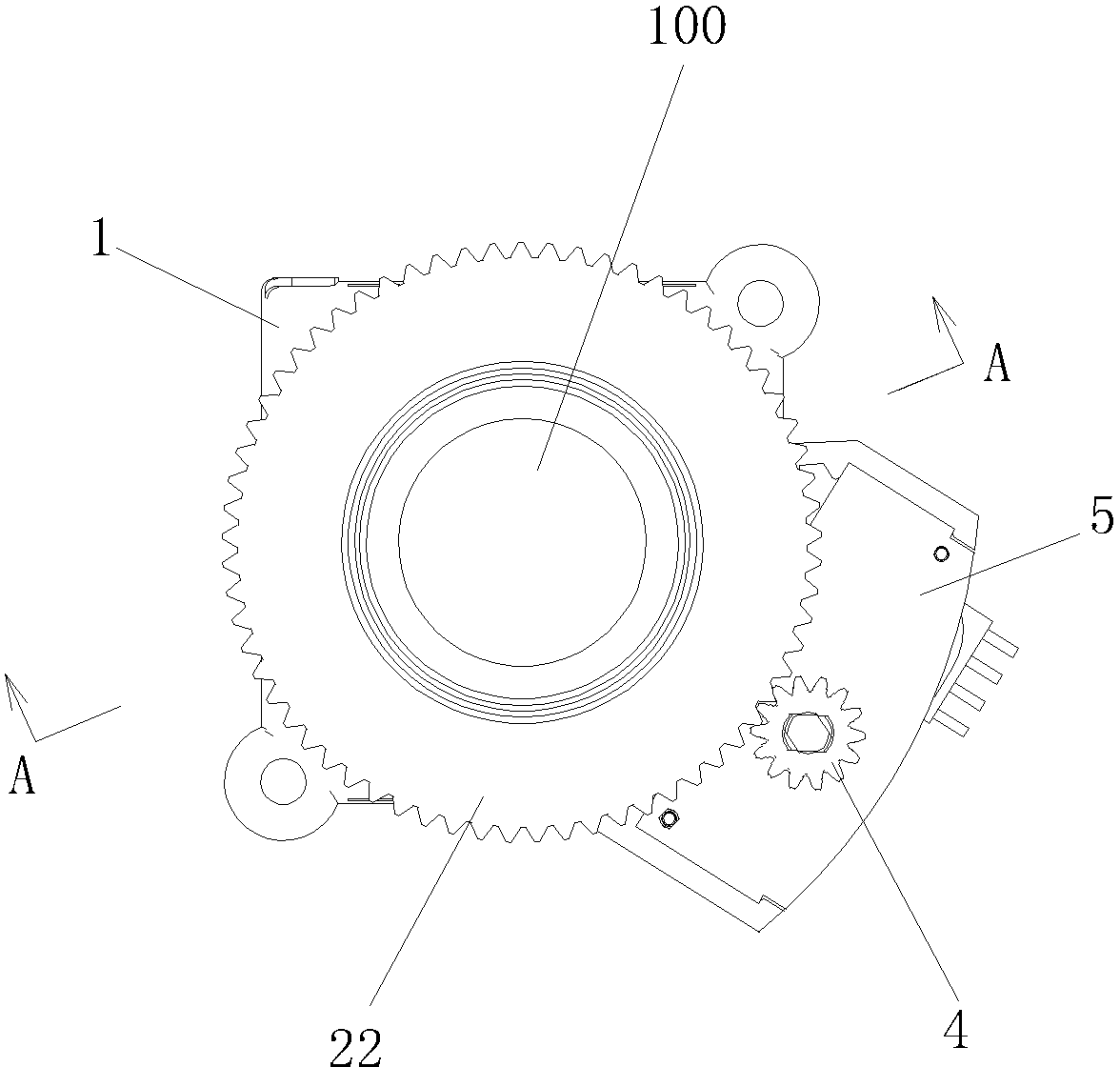

[0023] Embodiment 1. Figure 1 to Figure 8 As shown, a focusing mechanism for a monitoring lens includes a support base 1, a circular through hole 11 is provided in the middle of the support base 1, and a rotating sleeve 2 is sleeved in the circular through hole 11, and the middle of the rotating sleeve 2 There is a lens connecting sleeve 3 for assembling the lens 100, the rotating sleeve 2 is uniformly distributed with three spiral guide holes 21 along the outer peripheral surface, and the inner wall of the circular through hole 11 is uniformly distributed with three axial elongated guide grooves 111, The outer side of the support base 1 is provided with a driving gear 4, the driving gear 4 is connected with the stepping motor 6 through a reduction mechanism 5 fixed to the support base 1, and the end of the rotating sleeve 2 is provided with a driven gear 22 and the matched with the driving gear 4;

[0024] The lens connecting sleeve 3 is radially locked with three guide pin...

Embodiment 2

[0029] Embodiment two, Figure 9 As shown, what is different from the first embodiment is that the rear end of the support base 1 is provided with an assembly thread 13, which is convenient for matching with a camera with an internal thread interface.

[0030] The working principle of the present invention is as follows: the end of the guide pin 7 is limited by the elongated guide groove 111 and can only move in the axial direction, the guide pin 7 is fixed with the lens connecting sleeve 3 , and the lens 100 is mounted on the lens connecting sleeve 3 , and the guide pin 7 passes through the helical guide hole 21 on the rotating sleeve 2. When the driving gear 4 drives the driven gear 22 on the end of the rotating sleeve 2 to rotate, the helical guide hole 21 on the rotating sleeve 2 drives the guide. The pin 7 moves in the axial direction, so the lens 100 moves along the guide pin 7 in the axial direction to realize automatic or manual focus adjustment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com