Exchange tube support and securing assembly for tube exchanger

A technology for fixing components and supports, applied to fixed tubular conduit components, heat exchange equipment, heat exchanger types, etc., can solve the problems of pressure head loss, high manufacturing cost, etc., and achieve the effect of reducing pressure head loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] definition

[0050] The term "ring" is understood to mean an element having a closed profile having a thickness and delimiting an internal space open on either side of the closed profile. Typically, the closed profile has a generally circular cross-section, but it may have a different cross-section, such as oval, oblong, etc.

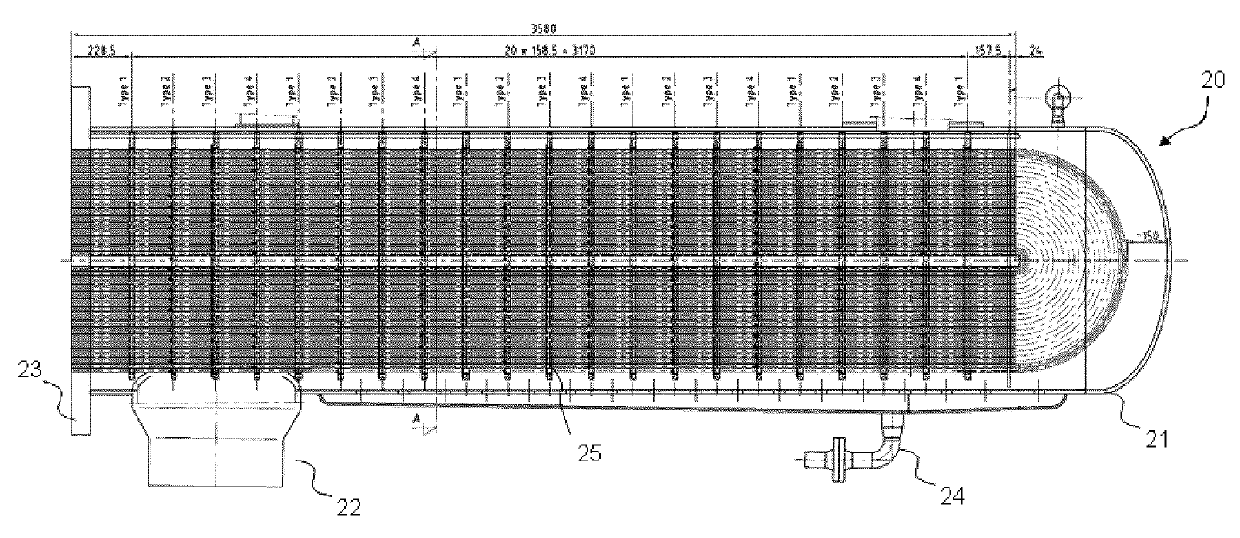

[0051] The term "column" is understood to mean the shell of an exchanger into which fluid is injected for its cooling or its heating, and includes rings such as those defined in the present invention. Typically, the post is cylindrical.

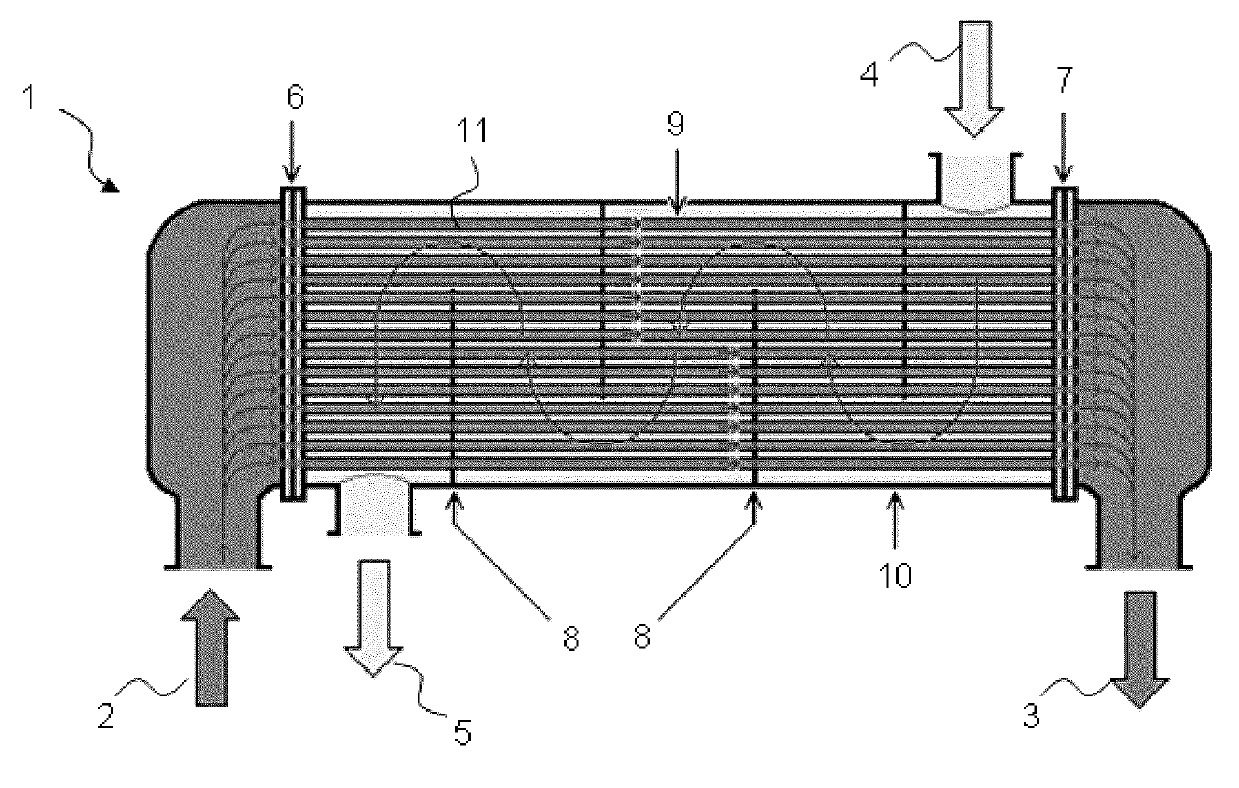

[0052] The expression "column and tube exchanger" is understood to mean an exchanger in which at least two fluids exchange heat, one fluid circulating in a column and a second fluid circulating in a tube. The surface of the tube acts as a support for exchanging heat between the two fluids.

[0053] The expression ""U"-shaped rod" is understood to mean an assembled or folded or bent rod forming three branches,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com