Construction method of track gauge variation block slippage of long span spatial composite roof truss

A construction method and pipe truss technology, which are applied in the processing of building materials, construction, building structure, etc., can solve the problems of large hoisting radius, difficulty, and extensive on-site cross-construction operations, and achieve broad application prospects and improve construction quality. , The effect of high construction precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

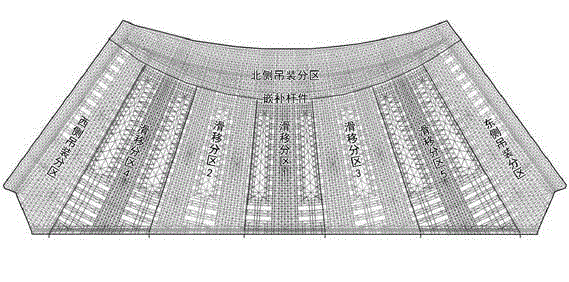

[0027] Such as figure 1 The long-span space pipe truss roof is described, and the roof is divided into five sliding partitions and three hoisting partitions; the construction method of the large-span space pipe truss roof variable amplitude and block sliding, the specific steps as follows:

[0028] (1) Divide the large-span space tube truss roof into five sliding partitions and three hoisting partitions;

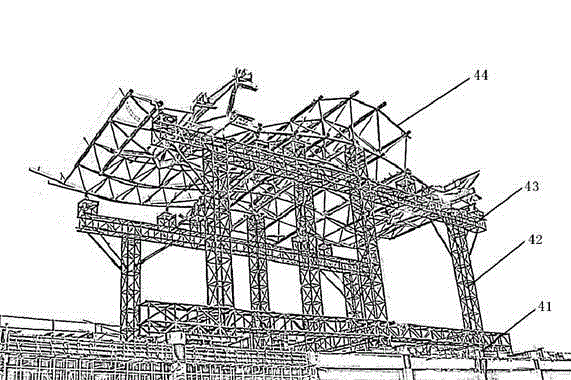

[0029] (2) Set up an assembly site in the airside area of the lobby to assemble the sliding supports for the sliding of each sliding area and auxiliary sliding area;

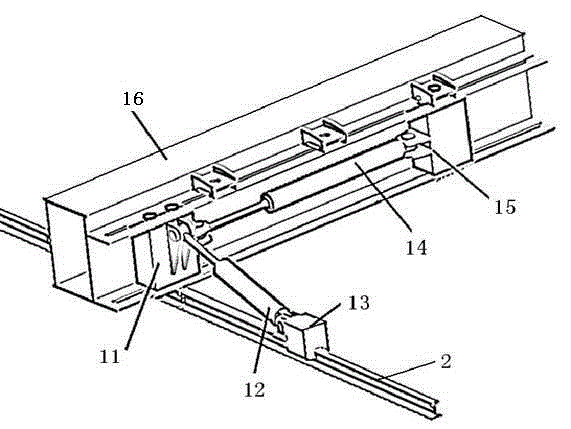

[0030] (3) After the sliding partition is assembled, it is disassembled into sliding blocks, and the sliding track is laid on the floor to be installed in the hall according to the radial position of the arc, and the sliding bracket and the sliding block are hoisted on the sliding track , and then carry out the radial accumulation slip together; the method of the radial accumulation slip installation is: s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com