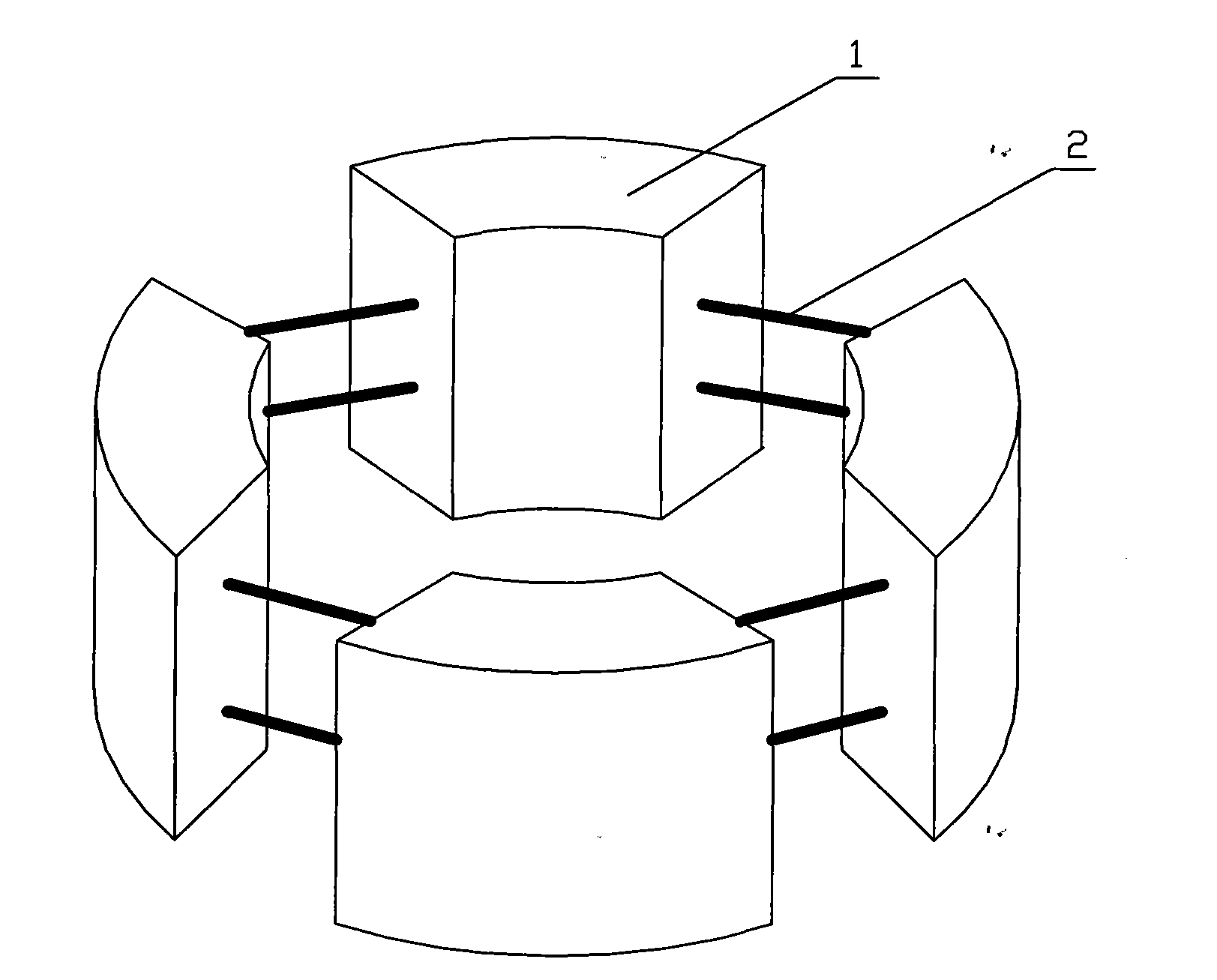

Construction method for adjustable arc-shaped beam cylindrical node assembling clamp

A construction method and technology of arc-shaped beams, which are applied in construction, building structure, processing of building materials, etc., can solve the problems of loss of turnover value, uneconomical, poor molding quality, etc., achieve appearance size and quality assurance, and improve work efficiency. and project quality, the effect of improving construction technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Example 1: Materials and Equipment

[0020] 1.1 Materials

[0021] 1.1.1 Use custom shaped steel formwork.

[0022] 1.1.2 When using the release agent, brush it evenly with a roller brush, and it must not flow, and it is strictly forbidden to contaminate the steel bars.

[0023] 1.1.3 See Table 1 for the construction material plan.

[0024] Table 1 Construction material schedule

[0025]

[0026]

[0027] Note: The unit is not specified in the table: mm: mm

[0028] 1.2 Mechanical equipment

[0029] Chainsaws, hand saws, hand hammers, wrenches, spirit levels, steel tapes, line sinks, etc. required by the project must be in good condition, and repairs should be made in time if there are problems to ensure the needs of the project.

Embodiment 2

[0030] Example 2: Quality Control

[0031] 2.1 All the preparatory work before construction should be ready, and the machinery and equipment can work normally after inspection without hidden dangers.

[0032] 2.2 The commercial concrete used has a factory certificate and a raw material test report, and the strength grade and other properties of the concrete meet the design requirements and construction specifications.

[0033] 2.3 When pouring concrete, the polluted steel bars should be dealt with in time, the displaced steel bars should be sorted and reset in time, and the operation horseway should be built in advance when pouring the roof concrete to ensure the safety of the operators.

[0034] 2.4 It is strictly forbidden to add water to the concrete, and the remaining concrete on the ground shall not be added to the newly poured concrete.

[0035] 2.5 The cloth is uniform and the blanking height is limited. The formwork is tightly seamed and must have sufficient rigidity...

Embodiment 3

[0040] Example 3: Security Measures

[0041] 3.1 Before the concrete is poured, the vibrator should be tested. The vibrator operator should wear rubber boots and insulating gloves; the vibrator should not be hung on the steel bar, and the wet hand should not touch the power switch.

[0042] 3.2 When pouring arc-shaped beams and cylindrical concrete, an operating table should be set up, and the operator should not stand directly on the formwork or support to avoid slipping or breaking the support and falling.

[0043] 3.3 All operators should wear safety helmets; safety belts should be worn for high-altitude operations, and sufficient lighting should be provided for night operations. Temporary electricity use at the construction site is strictly implemented in accordance with the relevant specifications of the "Technical Specifications for Temporary Electricity Use at Construction Sites" JGJ46-88.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com