Interrupted type centrifugal melting body electrostatic spinning device

A melt electrospinning and melt technology, which is applied in textiles and papermaking, filament/thread forming, fiber processing, etc., can solve the problems of difficulty in industrialization, large-scale production, high production cost, and low spinning quality. , to achieve the effect of overcoming multi-needle blockage, simple equipment and improving spinning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described in detail below in conjunction with specific embodiments.

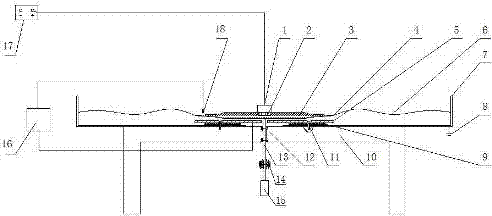

[0010] Such as figure 1 As shown, the concave depth of the feeding dish (2) is 1 / 2 of the thickness of the spinner (3), the cage bracket (1) is riveted on the upper surface of the spinner (3) by steel wire with good electrical conductivity, and the high-voltage power supply (17) Connected to the center of the top of the cage bracket (1), the diameter of the spinner (3) is 160mm, the angle between the tip is 8°, the pinhole nozzle (4) is located on the horizontal centerline of the wall of the spinner (3), and the diameter is 1mm , the spacing is 5mm, the outer wall of the spinner (3) is coated with a black coating to improve the radiation heat absorption rate, the heating plate (5), the heat insulating plate (9) and the receiving ring (7) are fixed on the On the base (10), prevent the shaking caused by the high-speed rotation of the rotating shaft (13) during the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com