Assembly line conveying device based on personal information modules and controlling method thereof

A technology of information modules and transmission devices, which is applied in the direction of conveyor control devices, conveyor objects, transportation and packaging, etc., can solve problems such as worker tension, production quality reduction, and quantitative evaluation, so as to reduce quality problems, improve efficiency, and alleviate problems. The effect of tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

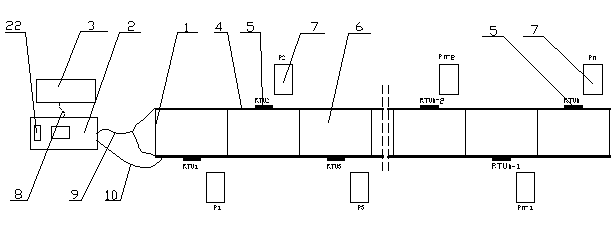

[0030] The present invention is described below in conjunction with accompanying drawing.

[0031] Such as figure 1 As shown, the assembly line based on the plug-and-play multifunctional personal information module: including the transmission line 1, the main control circuit board 2, the HMI operation interface 3, the quadruple metal guide rods 4 located on the two sides of the transmission line, and the quadruple Several plug-and-play multifunctional personal information modules 5 metal to the rod 4, the transmission line material box installed in the transmission line 1, the connecting cable 8 between the main control circuit board and the HMI operation interface, the main control circuit board and The connection cable 9 between the four metal guide rods of the transmission line, and the connection cable 10 between the main control circuit board and the transmission line.

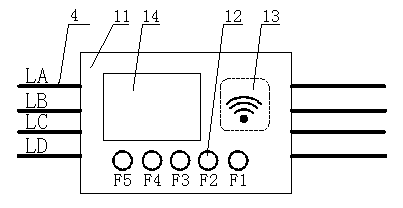

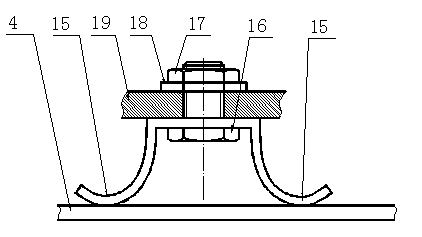

[0032] Such as figure 2 As shown, the plug-and-play multifunctional personal information module 5 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com