Automatic stereoscopic warehouse unit cargo self-aligning storage platform and alignment method thereof

A technology for three-dimensional warehouses and goods, applied in transportation, packaging, storage devices, etc., can solve the problems of relying on the technical level of workers, affecting storage efficiency, and increasing labor costs, so as to improve storage efficiency and automation level, and simplify delivery Steps, the effect of reducing labor requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention.

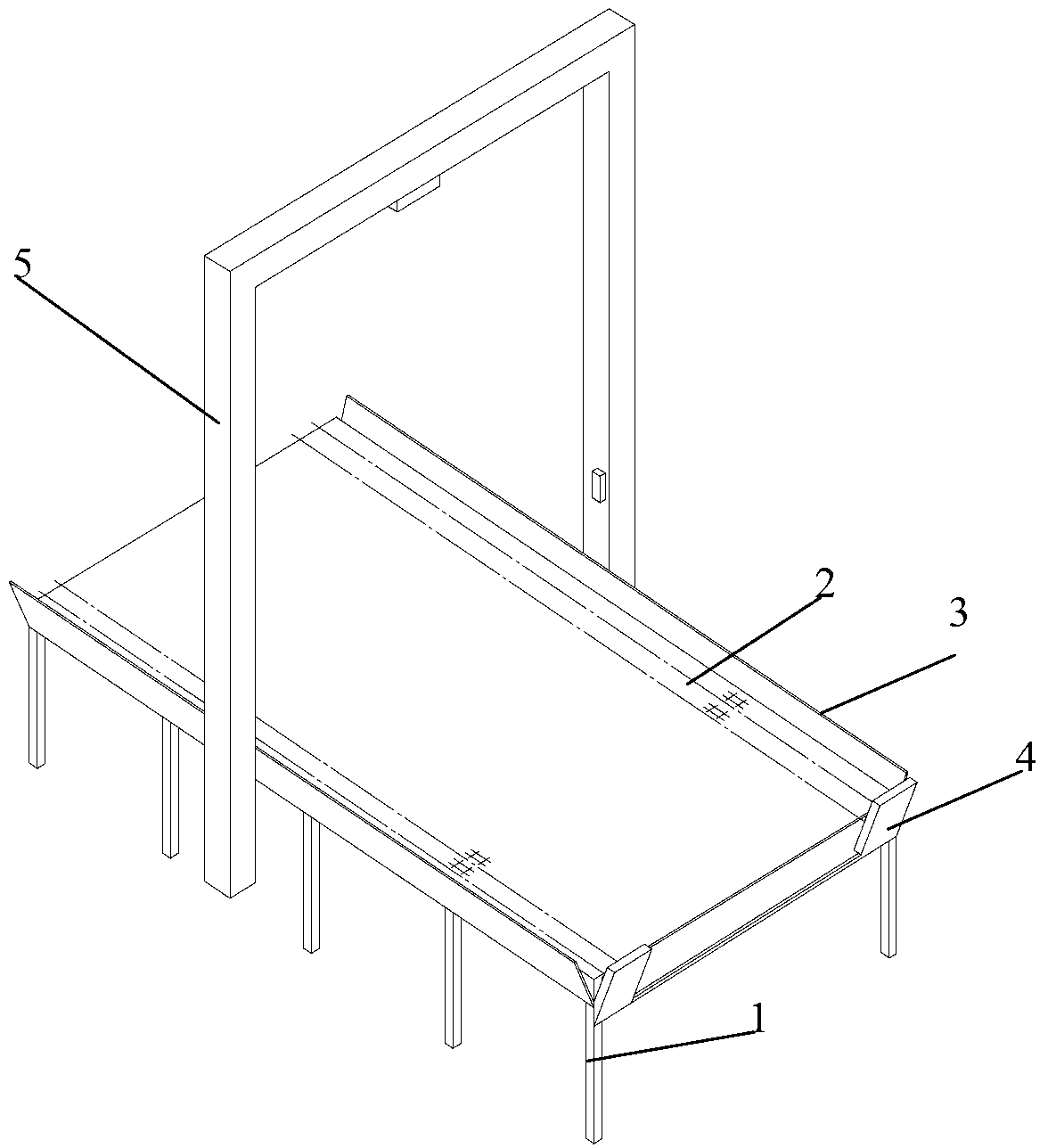

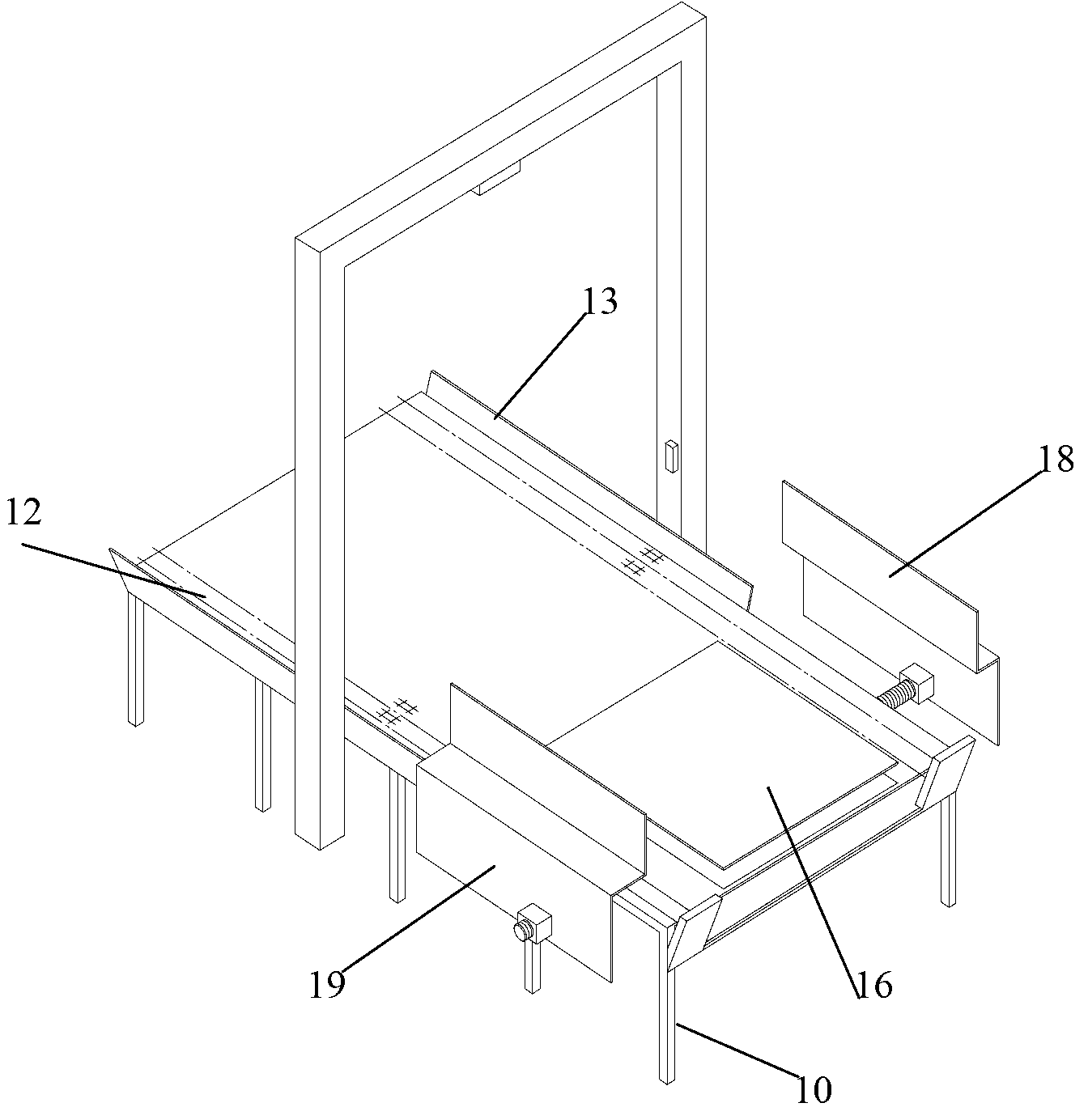

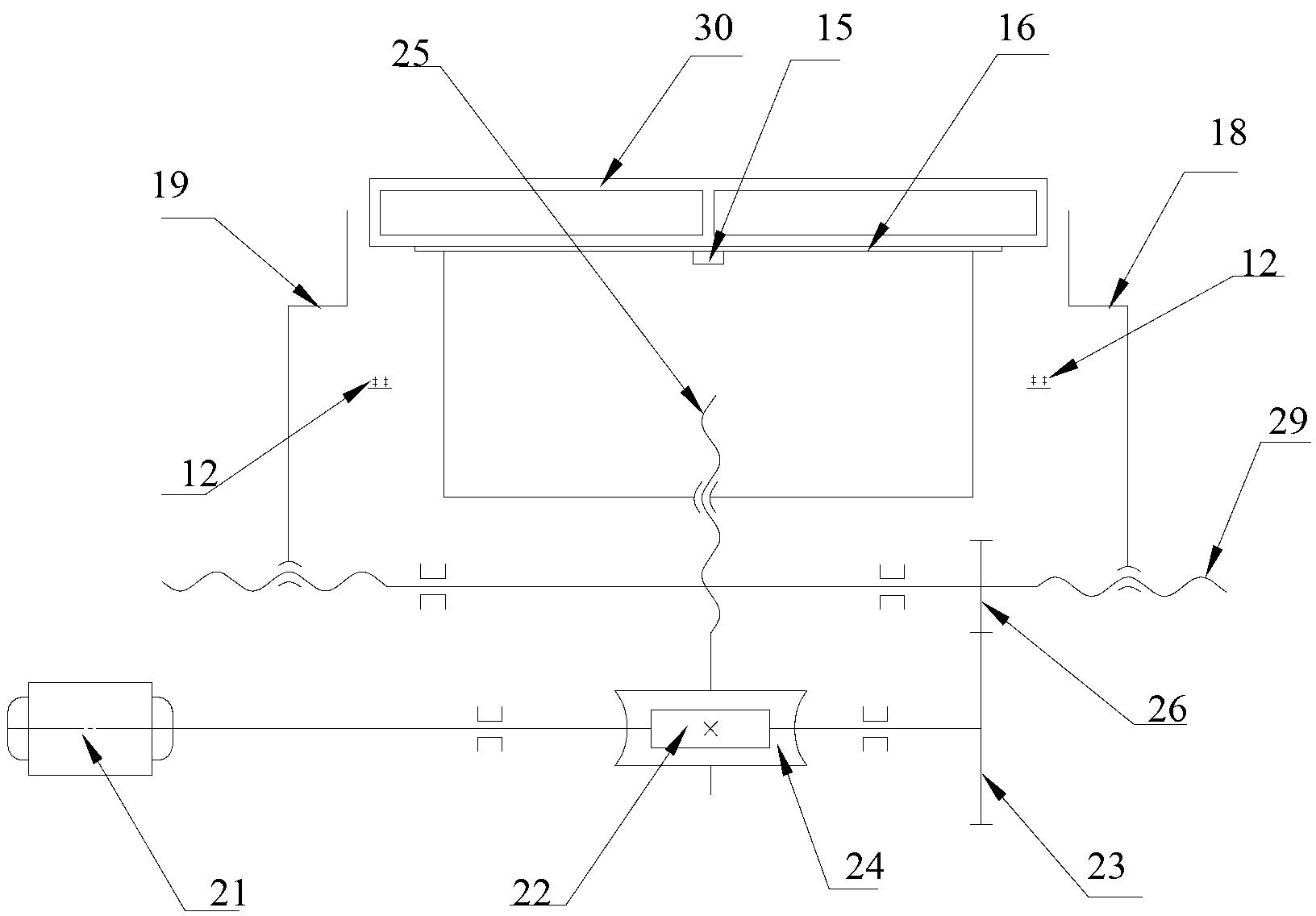

[0029] Such as figure 2 with image 3 As shown, the automated three-dimensional warehouse unit of the present invention automatically adjusts the warehousing station, including a rack 10, a chain 12 arranged on the rack for carrying and transporting the unit goods, and also including two chain receiving ends The receiving platform 16 in the middle and the correcting mechanisms arranged on both sides of the receiving platform 16. The receiving platform is provided with a weight sensor 17 and can be driven vertically to move up and down according to the change of the weight sensor signal. The righting mechanism includes respective The left centralizing plate 19 and the right centralizing plate 18...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com