Heating/cooling system for a vehicle battery and operation method for the same

A technology for motor vehicles and batteries, applied to heating/cooling equipment, batteries, secondary batteries, etc., can solve problems such as complex structures, and achieve the effects of low cost, constant vehicle weight, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

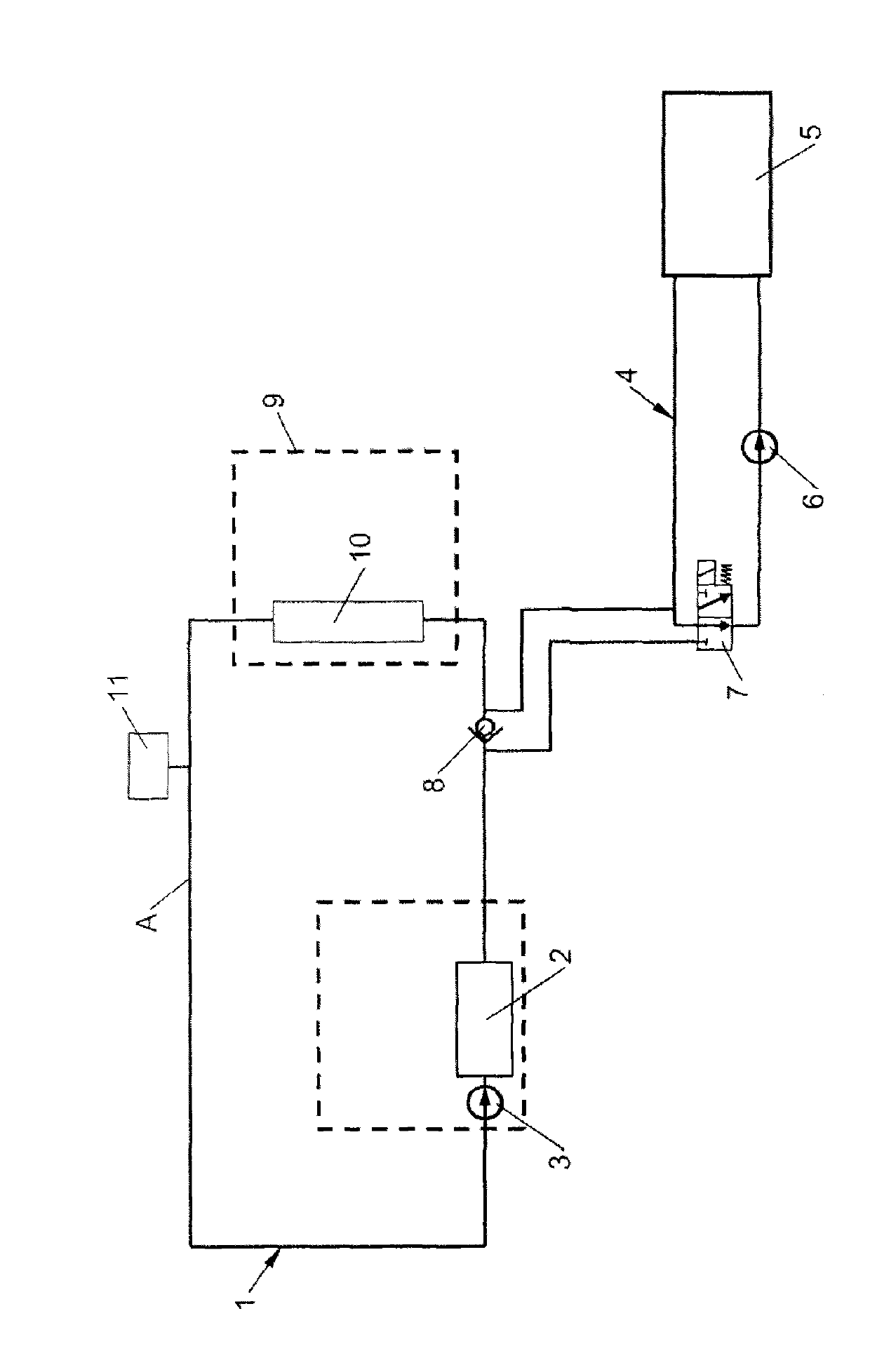

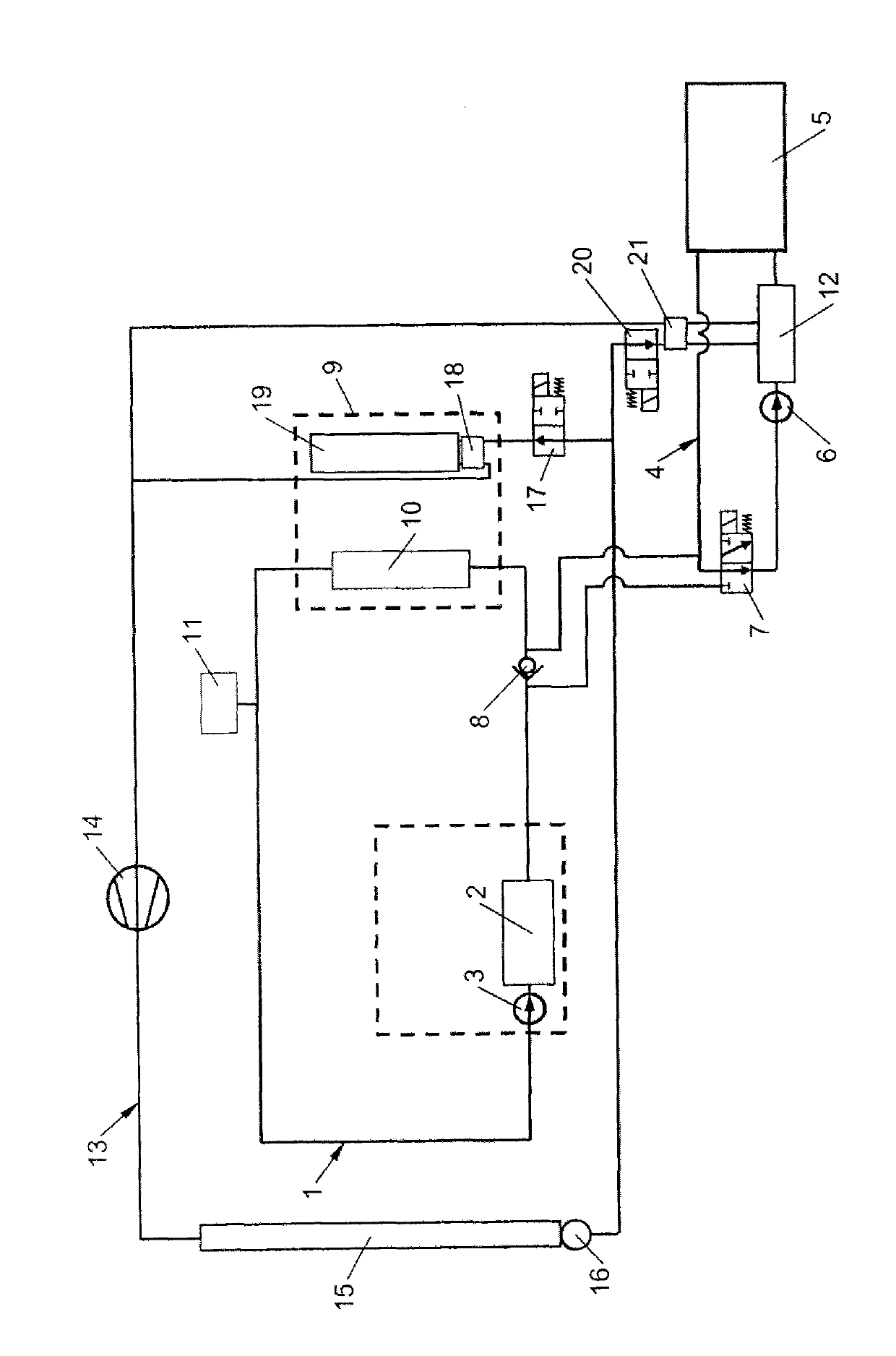

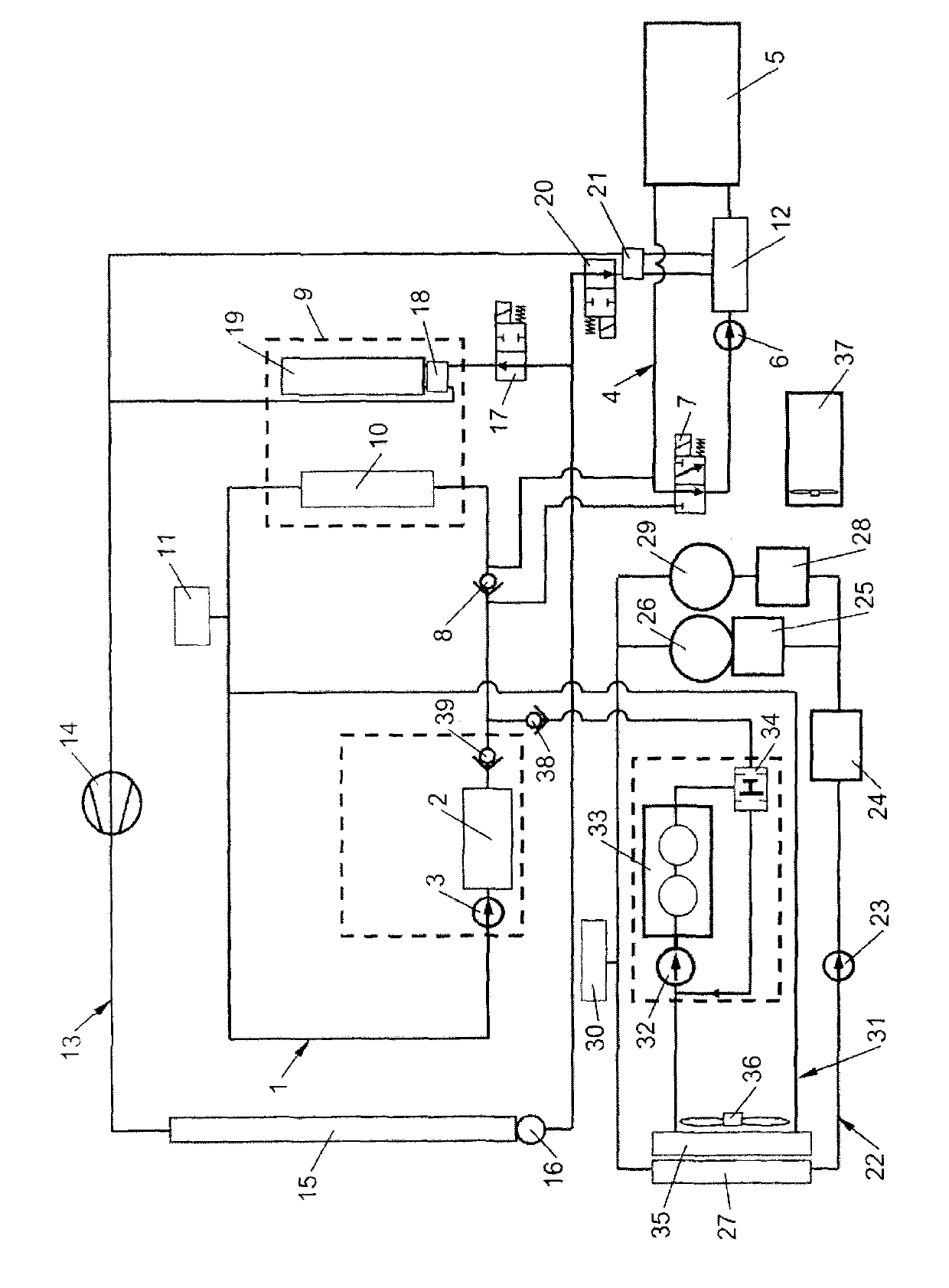

[0032] figure 1 Shown is a first heating circuit 1 with a heat source 2 arranged therein and a first pump 3 , and a second heating circuit 4 with a battery 5 arranged therein to be heated and a second pump 6 . The two heating circuits 1 and 4 can be connected via a valve 7 in such a way that the same liquid heating medium flows through these circuits. Specifically, the valve 7 is implemented as a clock-pulsed reversing valve, so that the heat exchange between the first and the second heating circuit 1 and 4 can be adjusted. Optionally, valve 7 can also be implemented as a mixing valve. In addition, the first heating circuit 1 also includes a check valve 8 arranged between the two connecting pipelines leading to the second heating circuit 4, a check valve 8 arranged in the figure 1 A heat exchanger 10 and a compensating tank 11 in the passenger compartment 9 of the vehicle of the arrangement shown in .

[0033] figure 1 The functionality of the device shown is as follows: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com