Guide die

A technology of guiding dies and guiding sleeves, which is applied in manufacturing tools, forging/pressing/hammer devices, forging/pressing/hammering machines, etc. The effect of improving the accuracy, increasing the guiding distance, and improving the guiding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

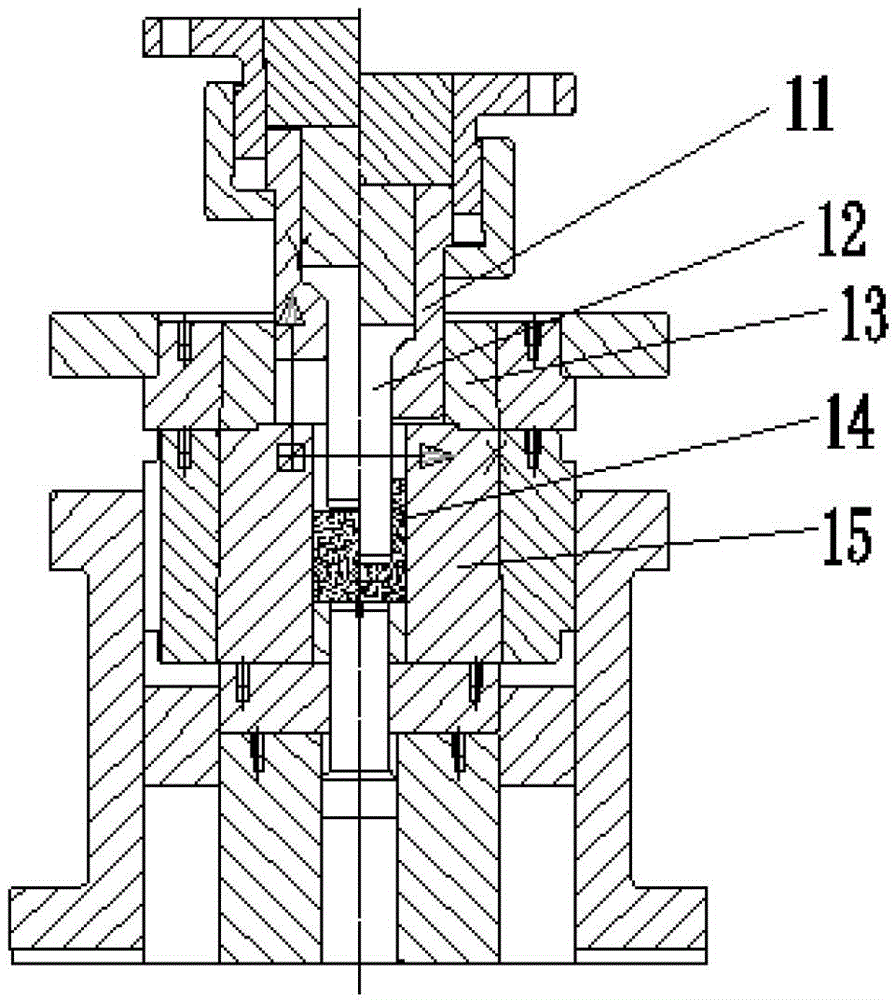

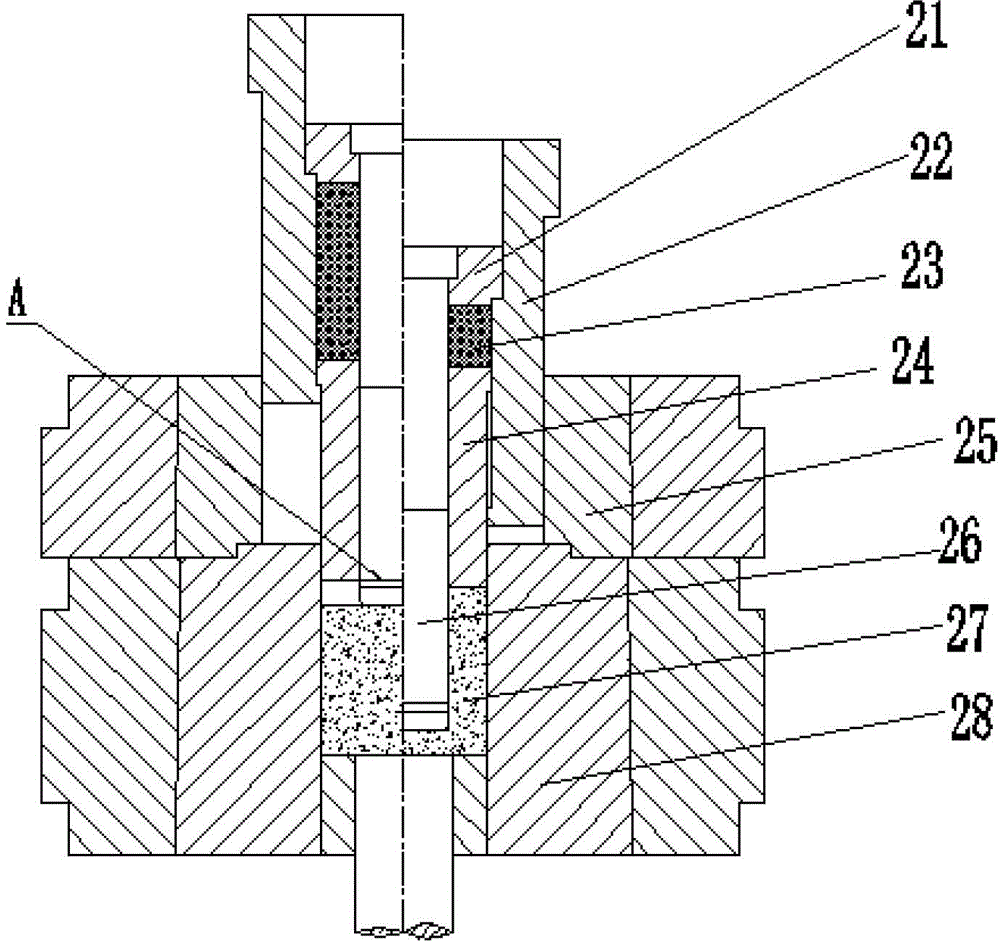

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0017] see figure 2 As shown, it is a structural schematic diagram of the guide die of the present invention. Such as figure 2 As shown, it includes a punch 26, a punch sleeve 21 sleeved at the root of the punch 26, a punch guide sleeve 24 sleeved at the end of the punch 26, wherein the punch sleeve 21 and the punch guide sleeve 24 are arranged There is an elastic member 23 . In this embodiment, the elastic component 23 is a buffer material for the mold, which may be a polyurethane elastomer. In other embodiments, the elastic component 23 can also be other cushioning materials with high elasticity and good flexibility, which should not damage the mold, be durable and easy to use.

[0018] read on figure 2 , which also includes a die 28 provided with a die cavity, and a forging blank 27 to be forged is placed in the die cavity. The side wall of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com